Products Description

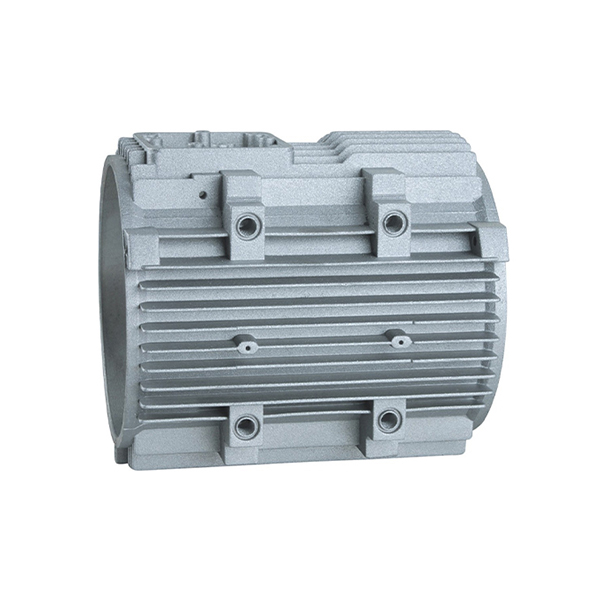

In the motor manufacturing industry, ductile cast iron and gray cast iron are commonly used to make motor shells. The motor shell is the outer shell of the motor, which mainly plays the role of protecting the internal parts of the motor and heat dissipation. For smaller power motors, gray cast iron is generally used, while larger power motors use ductile cast iron. Because of its high strength, good toughness, resistance to stretching, impact and abrasion, ductile iron is suitable for making motor shells that require a high degree of sealing.

Because the casting motor shell is softer, so commonly used in places where there is direct current, fast working speed but not much power; and ordinary cast iron motors in some driving force, the environment is relatively poor work will not be used in some places, the stability is not as high as aluminum, the cast iron motor shell of the motor running sound is also greater when working than the aluminum motor shell. The advantages of casting motor shell is light weight, good heat dissipation, good thermal conductivity, die-casting molding, good plasticity, elongation is higher than iron, low noise, good running stability.

The disadvantages are high price, low hardness, the advantages of high hardness, high resistance to external pressure, not easy to deform, cheap, can be installed in some driving force, the environment is relatively good work. But the disadvantages are heavy weight, poor thermal conductivity, not suitable for die-casting, poor plasticity, lower elongation than aluminum. Noisy, not as stable as aluminum. In short, the density of cast motor shell is relatively small, which can reduce the weight of the whole machine.