- Definition of structural components

Structural components refer to member parts used for fixing, connecting, supporting and transmitting force and power, and realizing mechanical structure. They are usually used in mechanical structures, building structures, vehicle and ship structures and other fields. Structural components mainly include fasteners, connectors, hinges and so on.

Second, the classification of structural components

- Fasteners: screws, nuts, etc. used to shorten the contact distance between pieces. Fasteners can be divided into metal materials, synthetic materials and non-metallic materials according to material classification.

- Connectors: components used to connect different components, such as bolts, nuts and washers. The materials and specifications of connectors are also very diverse.

- Hinges: components used to make two members rotate relative to each other along a specific axis, usually used in furniture, doors and windows. There are various forms of hinges, such as fan hinges, flat hinges, door pins and so on.

- spring: used to store and release mechanical energy components, usually used in machinery manufacturing, electrical and electronic industries. Springs can be divided into metal springs and non-metallic springs according to the material of the elastic material.

- Vibrators: used to convert electrical, mechanical or other forms of energy into vibration, usually including motors, sound and vibrators. The manufacturing materials and specifications of vibrators are also very diverse.

Third, the application areas of structural components

The application fields of structural components are very wide, and common fields include mechanical structures, building structures, vehicle and ship structures, electronic equipment, general-purpose hardware and so on. In these fields, the materials, specifications and quality of structural components will have different requirements and need to be selected according to different needs.

Fourth, the manufacturing materials of structural components

There are many kinds of manufacturing materials for structural parts, such as metal materials (e.g. steel, stainless steel, copper, aluminum, etc.), synthetic materials (e.g. plastics, fiber-reinforced composites, etc.) and non-metallic materials (e.g. rubber, ceramics, etc.). The manufacturing materials will be selected according to the application areas and requirements of the structural components, and different materials will have different characteristics and advantages.

Structural components are component parts used for fixing, connecting, supporting and transmitting force and power, realizing the mechanical structure, including fasteners, connectors, hinges and so on. The application fields of structural components are very wide, and the manufacturing materials are also very diversified, which need to be selected according to different needs.

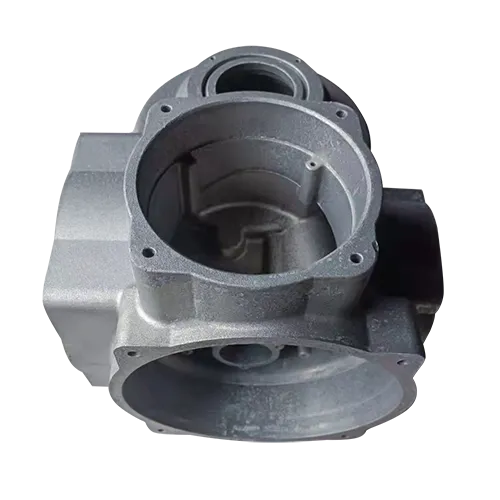

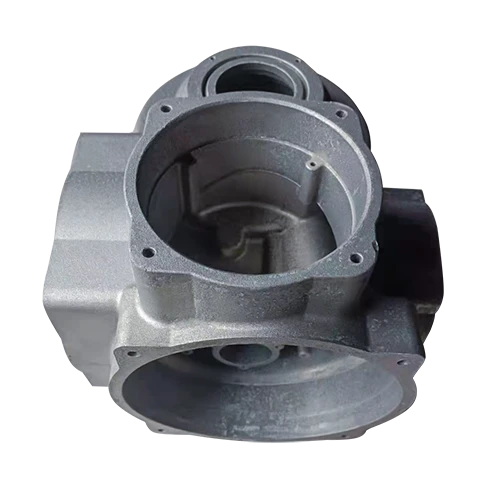

Link head castings are castings used to connect different components or systems, and are usually used in machinery, industrial equipment and other fields to realize the connection and transmission function between components. These castings are usually made of metal materials through a casting process and have high strength and durability. The design and manufacture of link head castings requires consideration of their manufacturability and structural elements to ensure that they are capable of meeting specific usage requirements.

Link head castings are used in a wide range of applications, including but not limited to:

Automotive engine components: such as cylinder blocks, cylinder heads, intake manifolds, etc. These components are often made from materials such as aluminum alloys to reduce weight and improve performance.

Industrial equipment: in a variety of industrial equipment, link head castings are used to connect and fix key components, such as pipe connectors, gearboxes, etc.

Special casting technology: With the development of science and technology, the traditional lost wax casting technology has been developed into new technology such as sequential solidification investment casting, which makes the production of link head castings more accurate and efficient.

In addition, the link head castings can also be customized according to specific needs, such as stainless steel castings for the production of non-standard accessories, such as hose couplings, quick couplings, etc. These products are widely used in a variety of industrial fields, such as hydraulic systems, pneumatic systems, etc., in order to achieve rapid connection and disassembly between components.

In summary, the link head castings are an indispensable part of the industrial field, they realize the effective connection between the components through the precision casting process and design, and improve the performance and reliability of the equipment.