First, the material of the casting cover

The material of the cover is usually the same as the casting itself, and the commonly used materials are aluminium alloy, cast iron, steel and so on. According to the different uses, the material of the cover can also choose plastic, rubber and other materials.

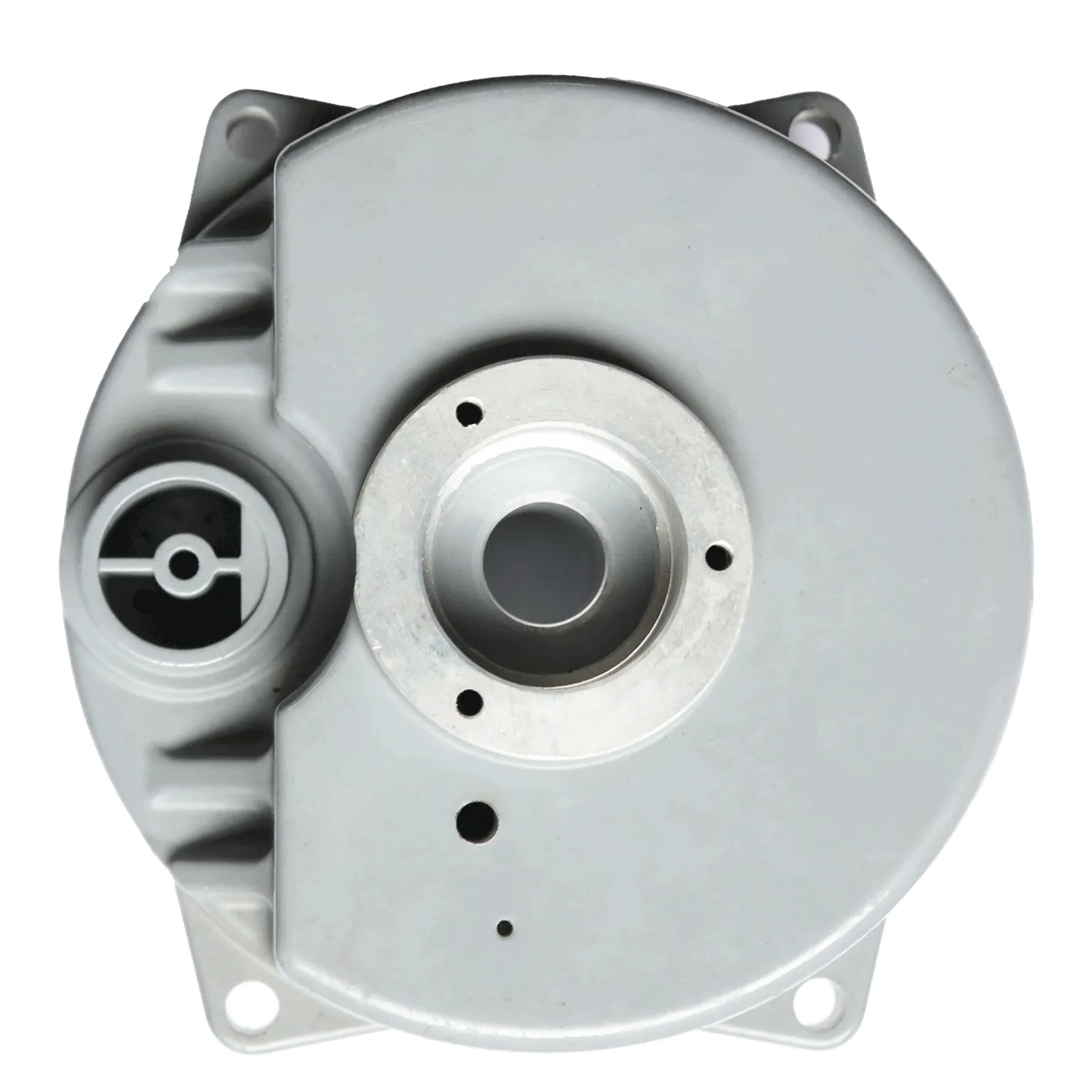

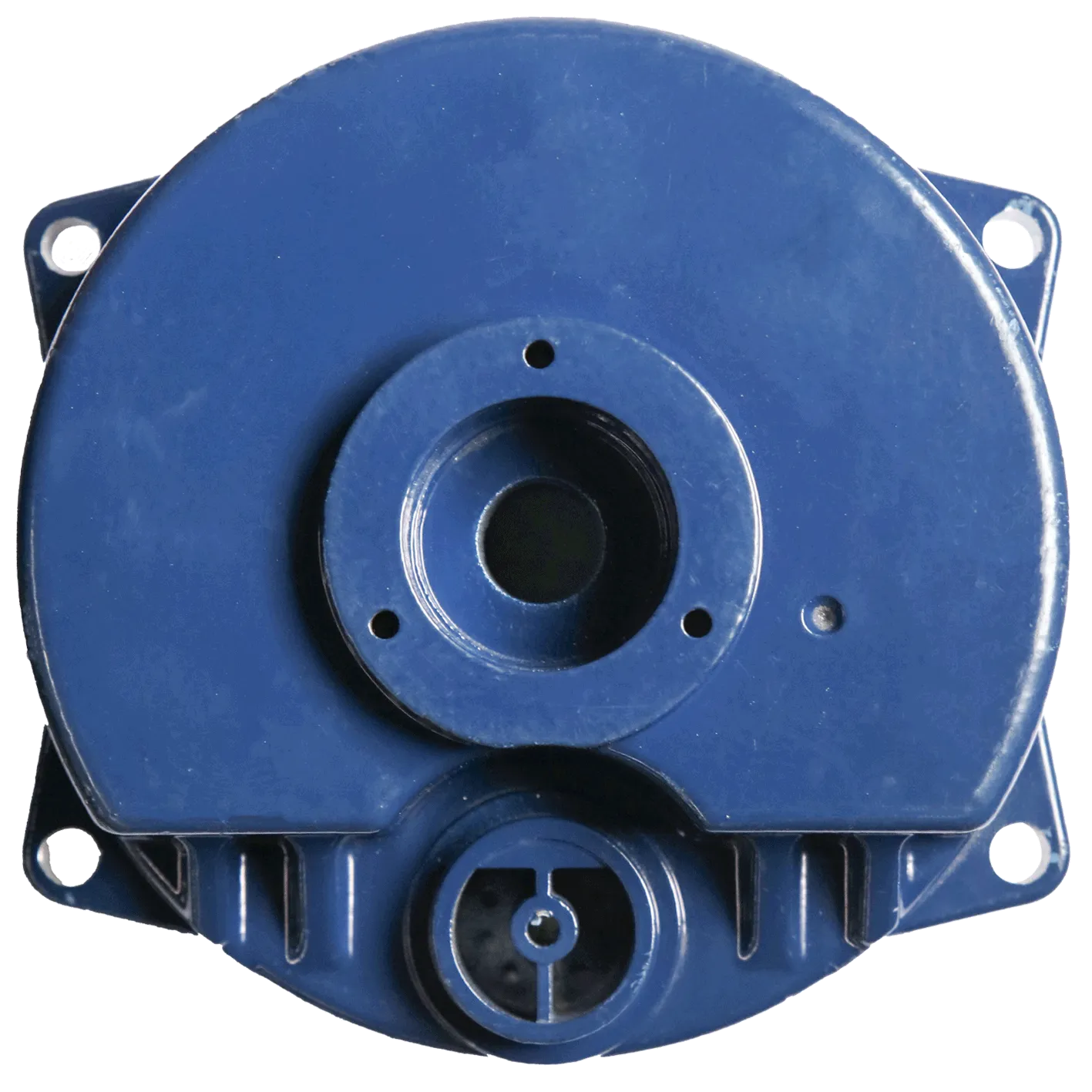

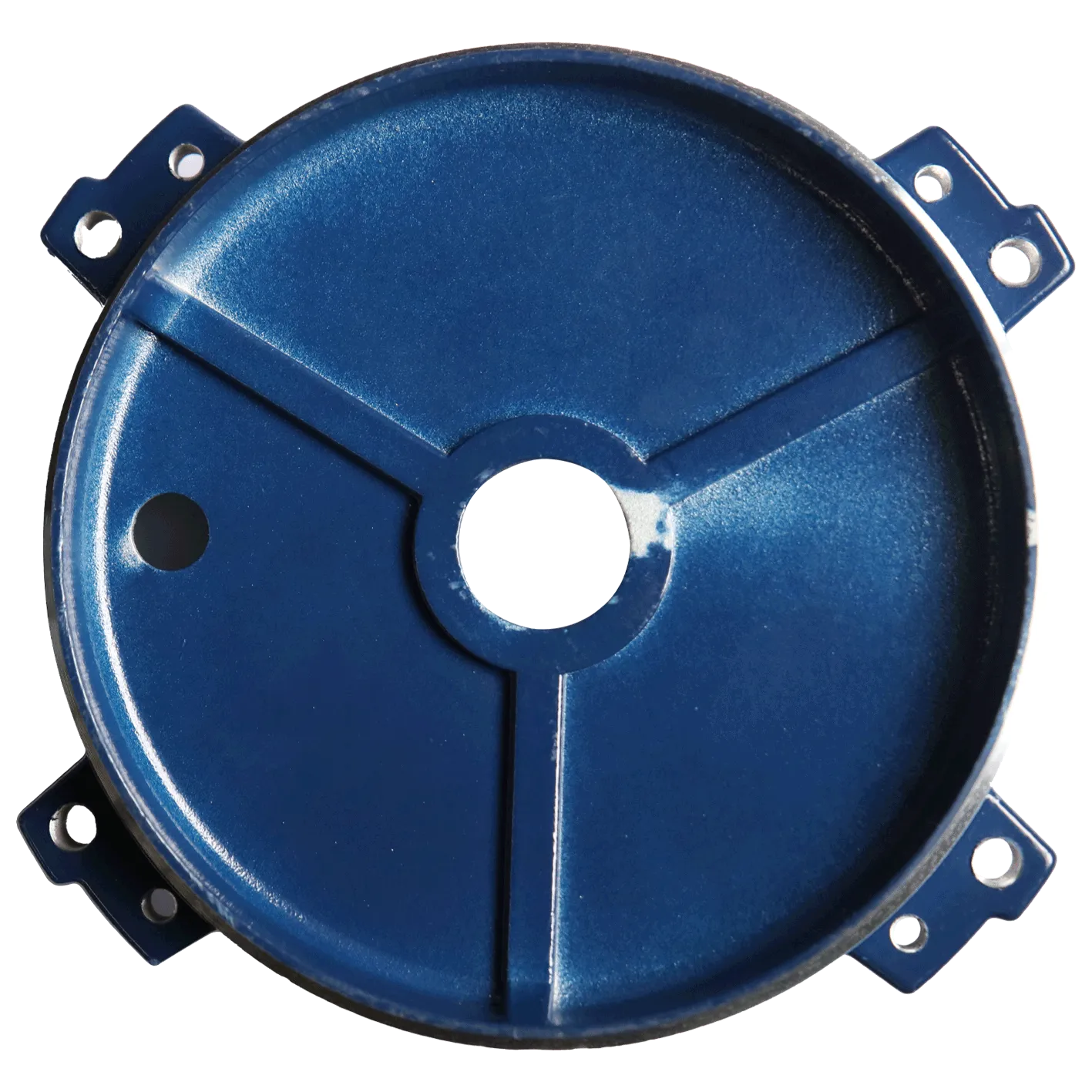

Second, the shape of the casting cover

The shape of the lid is generally designed and manufactured according to the shape and size of the casting. Common lid shapes include round lids, square lids, rectangular lids, triangular lids and so on. According to the use requirements of the lid, the edge of the lid can be flat, bevelled, rounded and other different shapes.

Third, the structure of the casting lid

The common lid structure has the following kinds:

- flat lid: the lid is parallel to the casting surface, commonly used in the need to seal the occasion;

- Convex lid: lid and casting surface presents a raised state, often used to prevent the casting is destroyed;

- recessed cover: the cover and casting surface shows a concave state, commonly used in fixed or sealed. 4;

- cover with support structure: the cover comes with a support structure, often used to increase the strength of the cover.

Fourth, the function of the casting cover

- protection: the cover can protect the casting from external forces and environmental influences, prolonging the life of the casting;

- support: the support structure of the cover can increase the strength and stability of the casting;

- sealing: flat cover and raised cover can realise the sealing of casting and prevent leakage;

- fixing: recessed lids can fix the position of the casting by lapping;

- Aesthetics: the shape of the cover design can beautify the appearance of the casting.

Fifth, the characteristics of the casting cover

Strength: ductile iron material has high strength, its tensile strength ób ≥ 420MPa, yield strength ós ≥ 300MPa, the same as low carbon steel material, grey iron material is three times 1.

Good toughness: the impact value of ductile iron is similar to medium carbon steel, grey iron material is more than 10 times 1.

Good plasticity: the elongation of ductile iron is ≥7%, which is similar to that of high carbon steel, while the elongation of grey iron material is zero1.

The use of casting cover

The casting cover is widely used in various fields, mainly used for water supply and sewage pipeline inspection wells, heating and gas inspection wells, postal, telecommunication and communication fibre-optic cable pipeline wells, electric power pipeline wells, street light wells, fire wells and various valve wells in urban construction. In addition, it can also be used for anti-corrosion engineering and open ditch cover 2.

The production process characteristics of casting cover

High strength: through the special heat treatment process, the strength and toughness of ductile cast iron is significantly improved.

Production process: the production process of ductile iron manhole cover includes casting and heat treatment, which ensures its excellent physical properties.