Automotive parts metal casting and processing technology performance analysis mainly involves the following aspects:

Casting technology: casting is one of the important processes in the production of automotive parts, accounting for about 15% to 20% of the total number of automotive parts. This process is mainly used for the production of power system key components and important structural components. Europe and the United States and other developed countries in the automotive industry in the automotive casting production technology is more advanced, good product quality, high production efficiency, environmental pollution is small. These countries generally use digital technology to enhance the casting process design level, casting scrap rate of about 2% to 5%. In contrast, China's automobile castings although the output is larger, but most of the value-added and lower technical content of the black castings, and the level of foreign countries with a large gap.

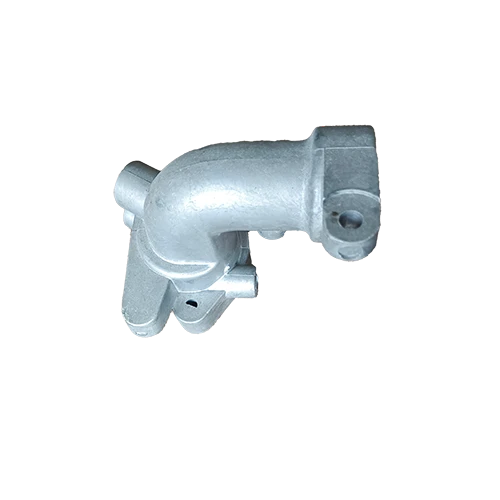

Die casting process: die casting process in modern automobile manufacturing plays a key role, through high pressure will melt the metal material into the mold, the formation of the precise shape of the parts, to ensure the dimensional accuracy and surface quality of the parts. This precision manufacturing process allows automotive parts to fit better with other components, improving the stability and performance of the entire vehicle. Die casting process can use a variety of metal alloys, such as aluminum alloys, zinc alloys, etc. These materials have excellent strength and durability, improving the safety and reliability of the car.

Semi-solid processing technology: semi-solid processing technology is a new type of process, mainly used in the production of integrated magnesium, aluminum alloy castings. This technology solves the problem of die-casting magnesium alloy performance and cost, so that the casting wall thickness can reach 1 ~ 1.5mm, pulling mold slope 1 ° -2 °. Foreign magnesium alloy in the automobile application of broad prospects, Europe and the United States domestic magnesium alloy die casting production to the annual rate of 25% growth. Magnesium alloy because of its light weight, high strength and good high temperature resistance, corrosion resistance, become the ideal material for automobile quality reduction.

Integrated design: with the automobile energy saving and environmental protection as well as reduce production cost requirements continue to increase, automobile casting integrated design has become the development trend. Through reasonable design and structural optimization, integrated parts casting forming, can effectively reduce the weight of the parts and reduce unnecessary machining processes, to achieve lightweight parts and high performance 1.

In summary, the development trend of metal casting and processing technology for automotive parts mainly focuses on improving production efficiency, reducing environmental pollution, improving product quality, and realizing the lightweight and high performance of parts. The development and application of these technologies are of great significance for improving the performance and safety of automobiles.