First, stainless steel valve body processing method overview

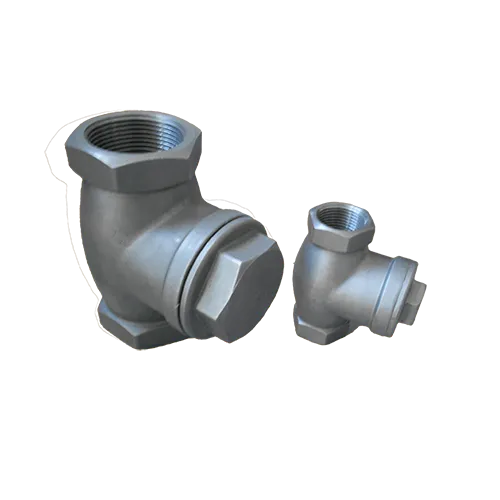

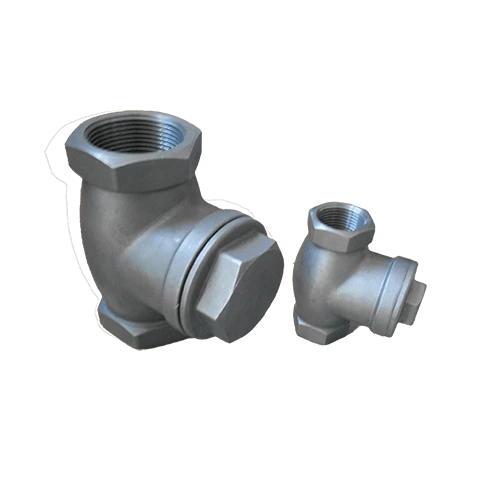

Stainless steel valve body is a common industrial valve, usually used to control the flow of liquid or gas in pipelines. In the manufacture of stainless steel valve body, there are a variety of stainless steel materials to choose from, so it is necessary to use professional processing methods in order to manufacture products of qualified quality.

Commonly used stainless steel valve body machining methods include milling, turning, stamping and so on.Among them, milling can be used to process the plane and curved shape of the stainless steel valve body, turning is mainly used for processing holes, shafts and surfaces and other parts, and stamping is used for processing metal plates.

Material selection is the first step in processing stainless steel valve body. According to the use of the valve body environment and the nature of the medium, select the appropriate stainless steel material. Commonly used stainless steel materials include 304 and 316L, which have good corrosion resistance, high strength, high temperature resistance and other characteristics.

Processing technology

Sphere processing: the raw material is cut into rods with similar diameters and formed into spheres through turning, milling, grinding and other processes.

Valve body processing: the processing of the valve body is also completed through turning, milling, boring and other processes in order to make a precise fit with the ball to achieve the sealing effect.

Valve assembly: the valve body, valve stem, valve seat, seals and other parts are assembled, generally using a combination of mechanical processing and manual assembly.

Surface treatment

Surface treatment generally adopts polishing, pickling and other processes to beautify the product appearance and improve corrosion resistance.

Suggestions for improving processing efficiency and quality

Use advanced processing equipment and processes, such as CNC machine tools and laser welding technology, to improve processing accuracy and efficiency.

Optimize the processing flow to reduce unnecessary processes and material waste.

Provide professional training to operators to improve operation skills and safety awareness.

Through the above steps and methods, you can effectively improve the processing efficiency and quality of stainless steel valve body to meet the needs of different application scenarios.

Second, stainless steel valve body processing methods

- Milling method

Milling is carried out on the CNC milling machine, in which the spindle and table can carry out a variety of different forms of movement in order to process different shapes of parts. When machining stainless steel valve bodies, precise dimensional control and surface finish are usually required. Therefore, the following points need to be noted in the milling process:

(1) Select the appropriate milling cutter and spindle speed;

(2) Reasonably set the feed rate and cutting depth to avoid overcutting or undercutting;

(3) Timely cooling and lubrication to avoid high processing temperature leading to surface quality degradation.

- Turning method

Turning is carried out on CNC lathes, usually used to process the holes, shafts and surface parts of the stainless steel valve body. The following points need to be noted in the turning process:

(1) Select the shape and material of the tool, and adjust it according to the size of the part and process requirements;

(2) Reasonably set the feed rate and spindle speed to avoid overcutting or undercutting;

(3) Clean the cutting fluid regularly to ensure the quality of the workpiece surface.

- Stamping method

Stamping is a process method of processing metal sheets into the desired shape by pressure. In the processing of stainless steel valve body, usually need to control the thickness and strength of the plate, in the stamping process also need to pay attention to the following points:

(1) Select the appropriate mold according to the requirements of the workpiece to ensure accurate processing dimensions;

(2) Reasonable arrangement of punching sequence, to avoid affecting the processing of the next process;

(3) Processing process of mold and plate maintenance and maintenance, to ensure processing quality and productivity.

Third, stainless steel valve body processing considerations

In stainless steel valve body processing, in addition to the above methods, but also need to pay attention to the following details:

(1) Select the appropriate processing tools and materials when processing;

(2) Strictly control the processing size and surface accuracy to ensure product quality;

(3) Pay attention to safety during machining to reduce the possibility of accidents;

(4) Strengthen the maintenance and care of equipment and tools to extend the service life.

Fourth, the summary

The above introduces the stainless steel valve body processing methods and precautions, each processing method has its own characteristics and applicable scenarios, in the actual production need to choose the appropriate processing method according to the specific circumstances. Attention to detail is required in the processing process to ensure product quality and productivity.