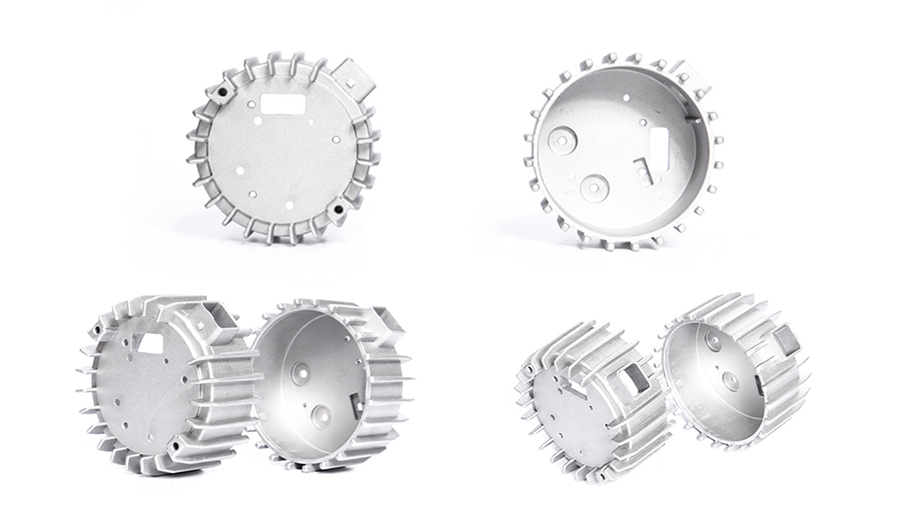

Products Description

Die casting radiator is a radiator manufacturing technology that injects molten metal into the mold through high pressure and subsequently die-casts it against the form. It has the advantages of high molding efficiency, good dimensional accuracy, high strength, no seams, etc., and is widely used in various fields. Aluminum alloy is currently the most commonly used die-casting radiator material, its low density, good thermal conductivity, strong processing performance and other characteristics can meet the basic requirements of radiator materials.

At the same time, aluminum alloy also has excellent corrosion resistance, mechanical strength and reliability, which can meet the needs of various fields such as automotive, engineering machinery, motorcycles and compressors. Among them, ADC12 aluminum alloy is the most commonly used die-casting radiator material.

Aluminum alloy radiator die casting is a manufacturing process that uses aluminum alloy material to fill a mold with molten aluminum alloy through high-pressure injection, and then cools and solidifies. The advantage of this process is that it can accurately shape complex radiator structures, while the superior thermal conductivity of aluminum alloy can quickly transfer heat and improve heat dissipation efficiency. Advantages of aluminum alloy radiator die casting:

(1) Lightweight and sturdy: aluminum alloy heat sink die-casting products have lightweight characteristics, which not only reduces the overall weight, but also maintains sufficient structural strength, making it an ideal choice for electronic equipment.

(2) Excellent thermal conductivity: aluminum alloy heat sinks have better thermal conductivity than other materials, which can quickly transfer heat to the heat sink and accelerate the heat dissipation process, effectively guaranteeing the normal operation of the equipment.

(3) Strong customization: Aluminum alloy radiator die-casting process is flexible and diverse, and can be personalized according to the needs of different equipment, to meet the heat dissipation requirements in different scenarios.

(4) energy saving and environmental protection: aluminum alloy radiator is recyclable and reusable environmentally friendly materials, the manufacturing process reduces resource consumption, in line with the modern concept of energy saving and environmental protection.

Aluminum alloy radiator die casting is widely used in all kinds of electronic equipment, such as computers, servers, televisions, smart phones, etc., as well as automobiles, new energy vehicles and other means of transportation. In high-performance processors, graphics cards, chips and other core components, aluminum alloy radiator is an indispensable key component.