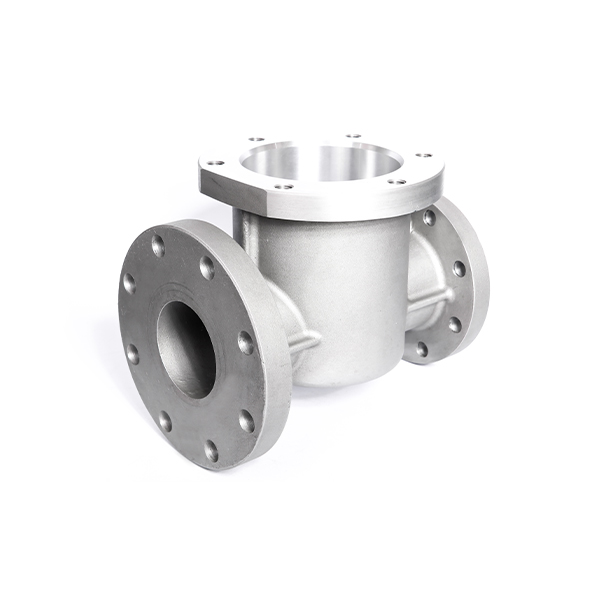

Products Description

Valve bodies and engine intake castings are important components in an engine. Valve bodies are typically used to control the direction of fluid flow, such as intake and exhaust valve bodies in automobile engines. These castings are usually made of cast iron, aluminum alloy or steel and have good wear and high temperature resistance. Engine intake castings, on the other hand, are the parts that connect the engine cylinder with the air intake port and play a role in guiding and distributing air flow.

Their design and quality directly affect the engine performance and combustion efficiency. Therefore, the selection and manufacturing process of these castings is very critical in the engine manufacturing process.

The inlet is one of the important parts of the supercombustion ramjet engine, and the main function of this part is to capture enough air and compress it with high efficiency to provide the combustion chamber with a certain pressure, temperature, speed and flow rate of the air, which plays a key role in realizing the hypersonic flight, and its working condition and dimensional accuracy directly affect the engine's thrust and efficiency, etc., and therefore, there are very high requirements on its performance and dimensional accuracy [1 Therefore, there is a high demand for its performance and dimensional accuracy[1-2].

At present, the inlet castings are developing towards lightweight, complexity and integrality, more and more use of large-size complex shaped surface of the thin-walled structure, the structure of this type of parts is irregular shape, such as polygons or shaped surfaces.