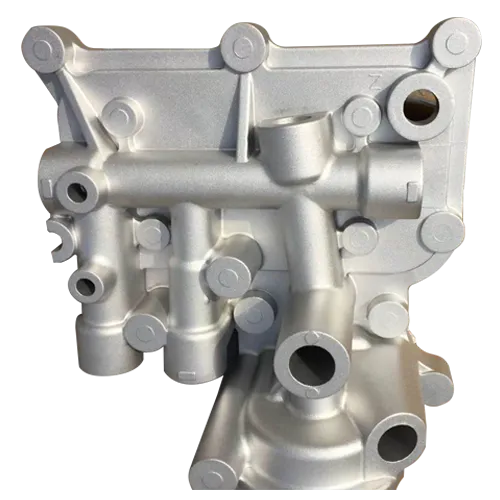

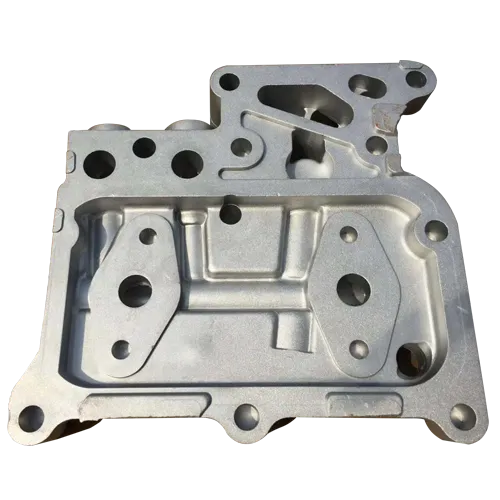

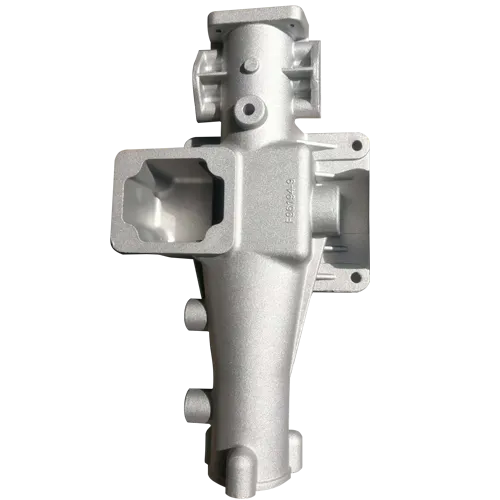

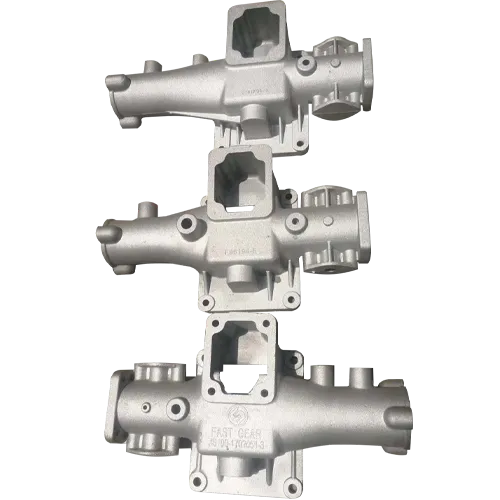

Aluminum alloy shell die casting

Aluminum die casting is the use of pressure to create the shape of the mold you need, usually by pouring a liquid substance into the mold to create an item that meets your needs for use.

The common base processes for die casting aluminum are annealing, normalizing, quenching, and tempering.

Annealing: In order to ensure that the material can have a more efficient cutting function, depending on the material, the appropriate temperature is chosen to heat the material to achieve the effect you want.

Quenching: The material is treated at a high temperature, and when the material rises to a certain temperature, it is cooled with water or other inorganic salt liquids to achieve the effect of making the material stronger.

Tempering: The method of quenching makes the steel brittle, and in order to reduce the brittleness, tempering was derived, which means that the material that has undergone quenching is put into an extremely high temperature environment of 650 degrees, and then cooled down again, so as to achieve the desired degree of hardness.

Aluminum alloy shell has the characteristics of high strength, high rigidity, corrosion resistance, wear resistance, good heat dissipation, etc., and many demanding application scenarios use aluminum alloy shell products. OuYuanda's automobile related accessories shell, connector shell and other precision hardware shell die casting has been affirmed and supported by customers.

Finally, aluminum die casting and aluminum materials can reduce human resources, more in line with the requirements of green environmental protection. The most important thing is that its fluidity performance can meet the various requirements of everyone, manufacturing a variety of finished molds, so it is also one of the most popular choices in the market at present.