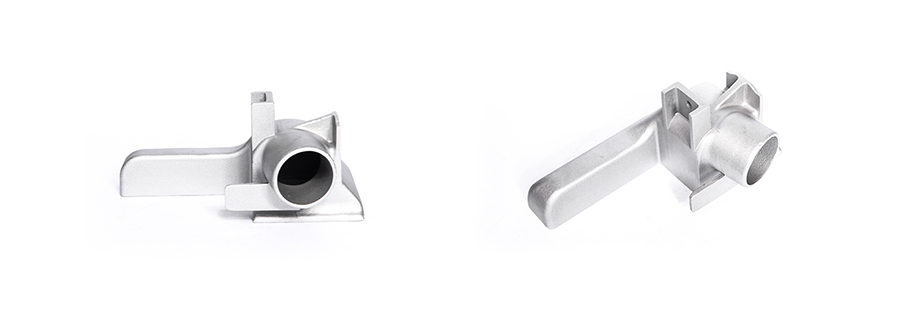

Products Description

Radiator tank castings are usually parts made by casting process for the tank part of the radiator. This casting is usually made of aluminum alloy or copper alloy, which has good heat dissipation performance and strength. Radiator tank castings are widely used in automobiles, industrial equipment and household appliances for cooling and heat transfer of radiators. Manufacturing radiator tanks through the casting process enables the production of complex structures, improves production efficiency and reduces production costs. These castings usually require precision machining and surface treatment to ensure that their quality and performance meet the requirements.

The automotive radiator is an important part of the automotive engine cooling system, and its role is to emit heat from the coolant (coolant) through the radiator core to reduce the temperature of the engine to ensure that the engine operates at normal operating temperatures.

The engine will produce a large amount of heat when working, if you can not dissipate the heat in time, it will lead to engine overheating, causing engine block, cylinder head, cylinder liner, valve and other parts deformation, damage, which leads to serious mechanical failure.

At the same time, the radiator can also keep the engine temperature stable, improve fuel combustion efficiency, reduce emissions of pollutants, save energy and extend engine life.