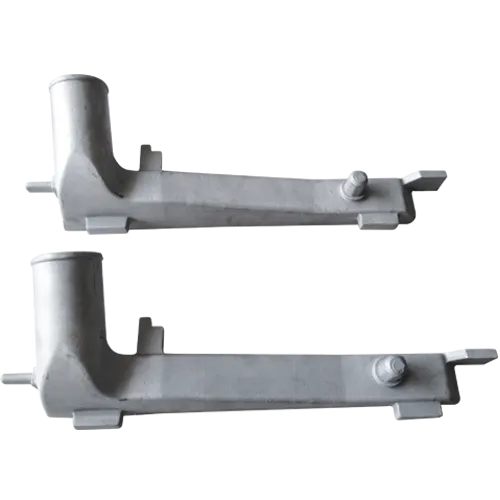

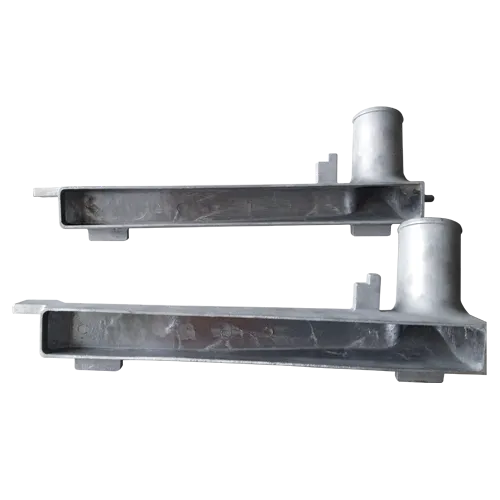

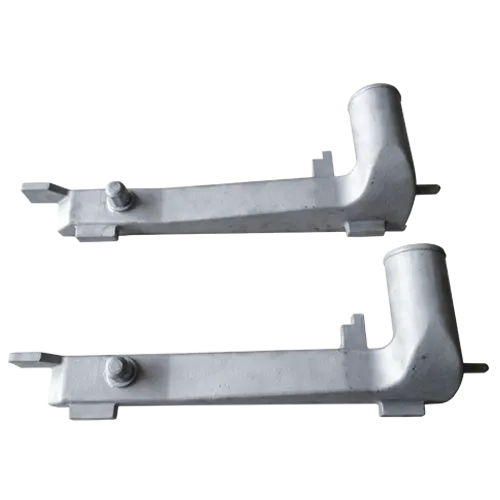

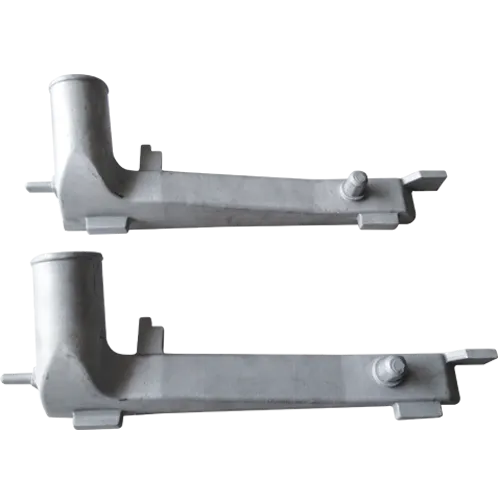

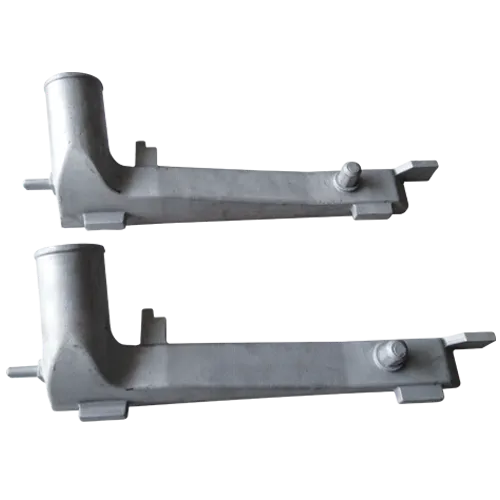

Intake pipe casting methods mainly include sand casting, precision casting and loss-in-weight casting three.

First, sand casting

Sand casting is a common casting method, suitable for various shapes of castings. In the production of air intake pipe, sand casting advantage lies in the production cost is relatively low, and the production process is simple, can adapt to the production of complex air intake pipe needs. At the same time, sand casting can also be used for the production of large and special shapes of the intake pipe. However, the sand casting precision and surface finish is relatively low, is not suitable for the surface finish and dimensional accuracy have strict requirements for the production of air intake pipe.

Second, precision casting

Precision casting is a high-precision casting method, suitable for a variety of complex shapes, surface finish requirements of high casting production. In the production of intake pipe, precision casting can be used for the production of complex shape of the intake pipe, at the same time can make the intake pipe surface finish and higher dimensional accuracy. However, the cost of precision casting is relatively high, applicable to the intake pipe precision has strict requirements of the scene.

Third, loss-in-weight casting

Loss-in-weight casting is a kind of advanced manufacturing technology applicable to the production of high-temperature alloy ultra-thin-walled rotor. In the production of intake pipe, loss-in-weight casting can be used to produce ultra-thin-walled, curved, complex shape of the intake pipe. Loss-in-weight casting can realize the directional solidification of high-temperature alloy, so that the intake pipe has better high-temperature performance and impact resistance. However, the cost of loss-in-weight casting is relatively high, and the manufacturing process also requires high equipment and technology.

In summary, the casting method of intake duct includes sand casting, precision casting and loss-in-weight casting. According to the shape, size and requirements of the intake pipe to choose the appropriate casting method can ensure the quality and performance of the intake pipe.