Overview

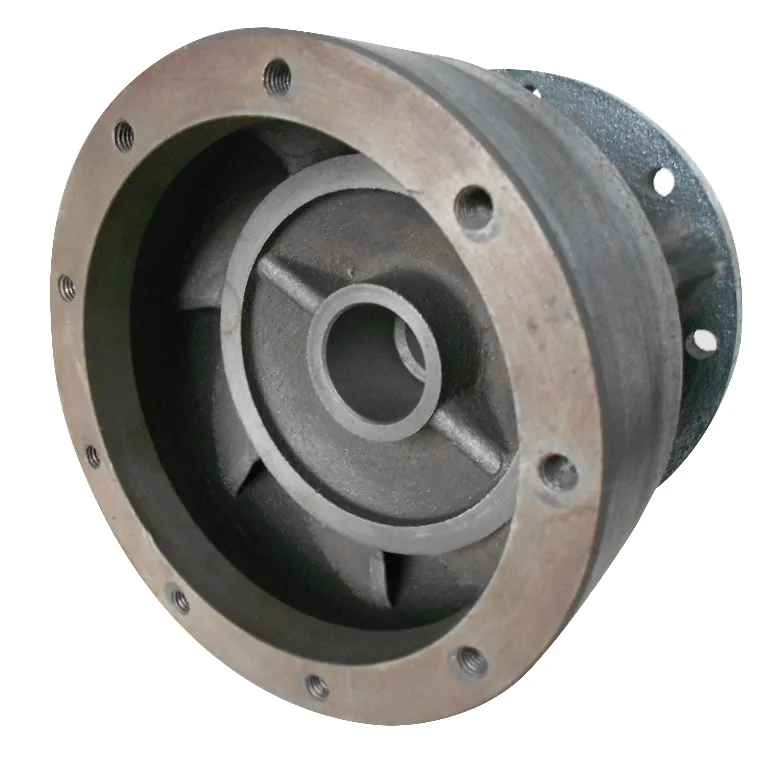

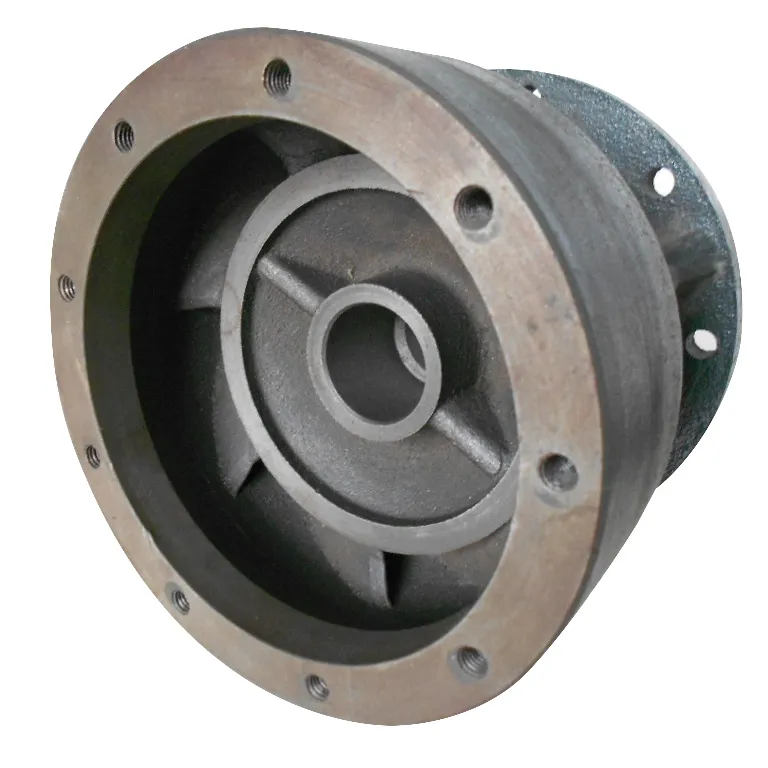

The deflector shell is an important functional component in aviation, track and other high-speed sports equipment, to ensure the safe and stable operation of high-speed sports equipment has a very important role. This paper introduces the specific steps and technical points of the casting process of the deflector shell.

Second, the choice of raw materials

Deflector shell material selection on the structure and performance of the deflector shell has a decisive impact. General selection of high temperature alloy materials for manufacturing, such as chromium, molybdenum and other metal materials. Also need to consider the thickness and density of the deflector shell and other factors to ensure the strength and stiffness of the deflector shell.

Third, the deflector shell casting process

1. Modeling: first of all, the three-dimensional drawing of the deflector shell is made into a solid model.

2. mold production: according to the solid model of the deflector shell to make molds, inside the mold pressing filler to ensure that the density and uniformity of the filler.

3. Melting and casting: melt the selected high-temperature alloy material and pour it into the mold for melting and casting to ensure uniformity of melting and casting to avoid thermal cracking.

4. Cooling: to be melting and casting is completed, the mold will be placed in a naturally ventilated place for cooling, not to be taken out in a hurry.

5. out of the mold: after cooling, open the mold and take out the infusion shell. At this time, the shell is still in a semi-finished product state, need to be further processed and treated.

6. Side pressure, machining: the deflector shell will be side pressure processing and machining to ensure the surface finish and dimensional accuracy of the deflector shell.

Precautions

1. Choose suitable material and manufacturing process to avoid strong thermal deformation and friction wear of the deflector shell in high-speed movement, which will lead to equipment damage and other safety problems.

2. in the process of melting and casting, make sure that the melting and casting temperature is suitable, and control the parameters such as melting and casting time and pressure, so as to avoid defects such as porosity, inclusions, cracks and so on.

3. adopt natural ventilation method for mold cooling, avoid using rapid cooling and other methods to lead to deformation and cracks in the guide shell.

4. When machining, ensure the stability of the machine tool and the accuracy of the machining parameters to avoid vibration interference in the machining process.

Conclusion

The casting process of the deflector shell is a tedious job that requires specialized knowledge and technology. Select the appropriate material and manufacturing process, master the key technology of each step, in order to ensure that the quality and performance of the deflector shell to meet the requirements.

Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Write your message here and send it to us

Related PRODUCTS