Products Description

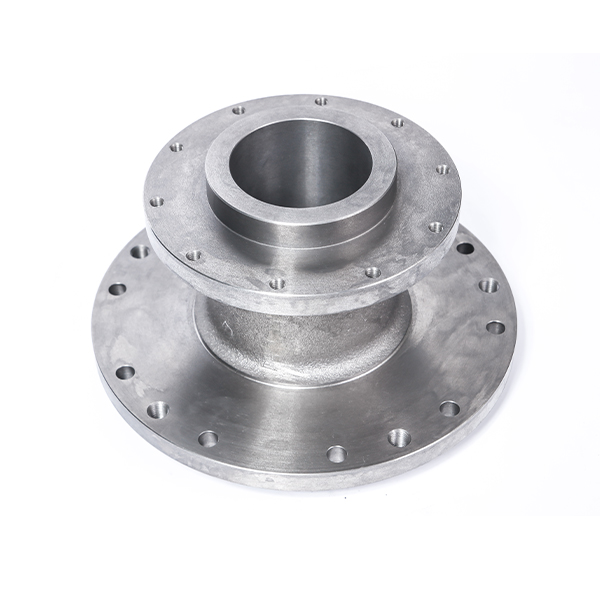

Connector castings are common parts in pump equipment that are used to connect different components or pipes. These castings are usually made of metal materials such as cast iron, stainless steel or aluminum alloys. The design and material selection of connector castings is critical to the performance and stability of pumping equipment. The right connector castings can ensure proper operation of pump equipment and reduce the risk of leakage or damage. When selecting connector castings, factors such as their corrosion resistance, wear resistance and ability to withstand pressure need to be considered. The efficiency and reliability of pumping equipment can be improved with quality connector castings.

Connector castings are common parts in pump equipment that are used to connect different components or pipes. These castings are usually made of metal materials such as cast iron, stainless steel or aluminum alloy. The design and material selection of connector castings is critical to the performance and stability of pumping equipment. The right connector castings can ensure proper operation of pump equipment and reduce the risk of leakage or damage. When selecting connector castings, factors such as their corrosion resistance, wear resistance and ability to withstand pressure need to be considered. The efficiency and reliability of pump equipment can be improved through quality connector castings.

Finished pump castings have high shape accuracy. In the casting process, the use of fine molds and advanced equipment can ensure that the finished pump castings have high shape accuracy. This is particularly important for pump parts, because the pump needs to have good sealing in the working process, shape accuracy directly affects the sealing performance of the pump.

Dimensional accuracy refers to the pump castings in the casting is completed, and the design drawings require a smaller size error. Dimensional accuracy is one of the important indicators of casting quality, especially critical for pump parts, because the pump's working performance and installation with the need to meet certain dimensional requirements.

Pump castings have a smooth surface, no sand holes, no air holes and other defects, which can reduce the subsequent machining process of repair and grinding process, improve production efficiency. And good surface quality can improve the efficiency and service life of the pump, reduce the failure rate of the pump.

Pump castings in the casting process, the use of advanced production technology and equipment, can realize mass production, improve production efficiency and product quality. Compared with the traditional casting method, the finished pump castings can reduce the subsequent processing procedures, reduce energy consumption and labor costs, and improve production efficiency.