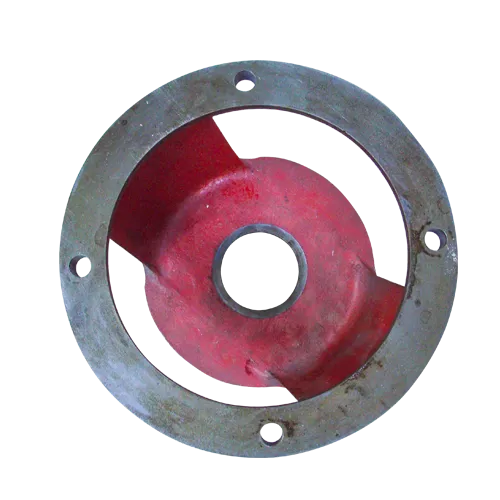

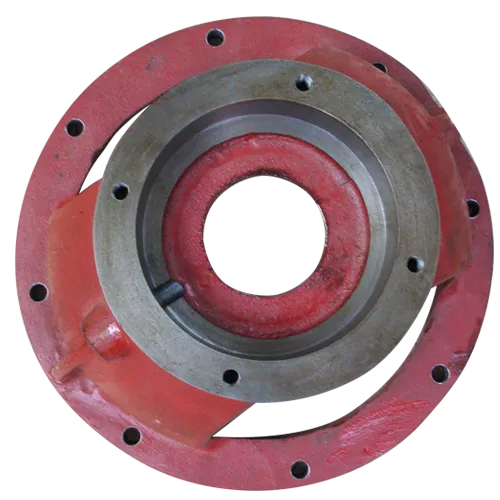

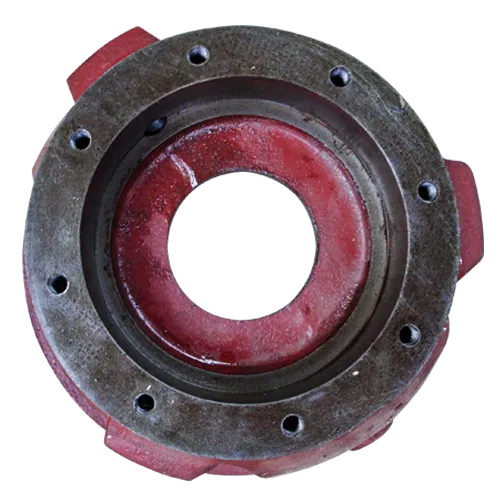

Stent casting parts brief introduction

Structural drawings and specifications: For the manufacture of stent castings, structural drawings and specifications are fundamental to manufacturing operations. Structural drawings need to be comprehensively labeled stent size, shape and surface roughness and other requirements. The specification includes the material, weight, volume and other parameters of the stent, as well as the applicable operating environment and operating conditions. Structural drawings and specifications need to be audited to ensure compliance with manufacturing requirements and relevant national standards.

Material selection and quality inspection: the material selection of the stent casting parts is crucial, taking into account the stent's load-bearing capacity, corrosion resistance, wear resistance and other factors. Commonly used materials include wear-resistant cast iron, cast steel, ductile iron and so on. When the material comes into the field, it needs to carry out quality inspection, including chemical composition analysis, mechanical properties test, etc., in order to ensure that the quality of the material meets the manufacturing requirements.

Casting technology and program: casting technology and program has a decisive role in the quality of the stent casting parts. Casting technology includes mold construction, melting, pouring, cooling and other sequences. Casting operations need to control the temperature, cooling rate and other parameters to ensure the dimensional accuracy and quality balance of the stent. The casting program needs to be carried out in accordance with the manufacturing program to ensure the manufacturing effect and product quality.

Quality inspection and control: quality inspection and control is an important means to ensure the quality of stent castings. Inspection content should include appearance inspection, dimensional measurement, internal quality inspection, mechanical properties test. The quality control system needs to be constructed to monitor and adjust the key parameters in casting operation in real time to ensure the quality balance of the stent.

Surface treatment: The surface treatment and coating of the stent casting possess an important role in its appearance, corrosion resistance, wear resistance and other properties. Common surface treatment methods include sand blasting, shot blasting, spray brushing and so on.

Assembly and debugging: assembly and debugging is the stent casting manufacturing operations in addition to the link. Before assembly, we need to check the size and connection of each component to ensure smooth assembly. In the debugging operation, we need to check the fixity and balance of the stent to ensure that the stent has balanced performance under normal operating conditions.

Packaging and transportation: Packaging and transportation is an important part to ensure that the stent casting parts are not damaged during transportation. Packaging materials need to have certain anti-pressure and anti-vibration properties to ensure that the stent is not subject to collision during transportation. At the same time, we need to choose the appropriate mode of transportation and route to ensure that the stent is delivered to the destination in a safe and timely manner.

In short, the manufacturing operation of stent casting involves many links, and each link plays a role in the formation of final product quality. Therefore, in manufacturing operations in accordance with the drawings and specifications, select the appropriate materials and technology, improve quality control and control to ensure product quality balance and reliability. At the same time, we also need to pay attention to environmental protection and safe manufacturing to ensure the balance and safety of manufacturing operations.