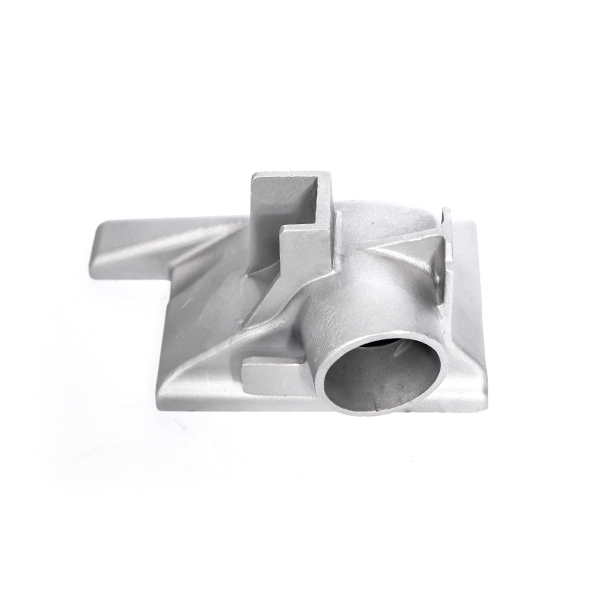

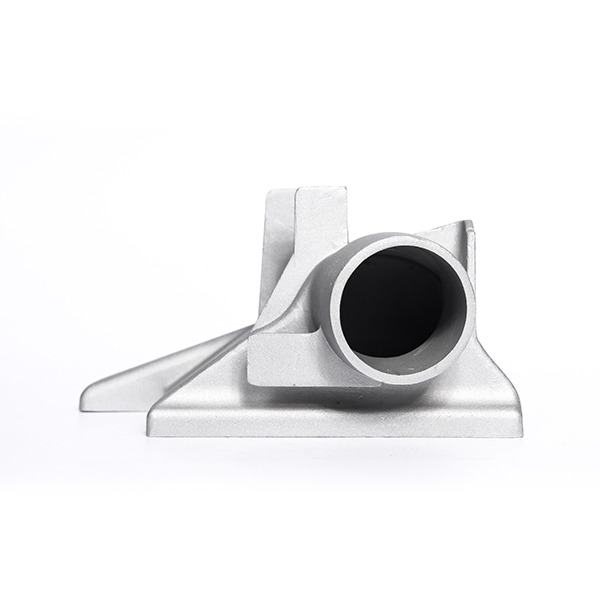

Products Description

Casting air chamber castings are usually used in the production of parts that require high quality, precision and surface finish, such as aerospace, automobile manufacturing and precision instruments. Through the rational design and use of air chamber casting technology, can effectively improve the quality and performance of castings.

Casting air chamber casting is a technology that controls the flow and solidification of metal liquids through the use of air chambers in the casting process. Air chamber casting can effectively reduce defects such as porosity, porosity and inclusions, and improve the quality and density of castings. During the casting process, the gas chamber can help expel gases from the metal liquid and induce the metal liquid to fill the mold evenly, resulting in a more uniform and stable casting.

Metal liquid molding has many processes and is difficult to control accurately, making the casting quality less stable. Compared with forgings of the same material, because of the loose organization and coarse grain size of liquid forming, it is easy to produce defects such as shrinkage, shrinkage and porosity internally.

Its mechanical properties are lower. In addition, the labor intensity is high and the conditions are poor. Have excellent mechanical and physical properties, it can have a variety of different strength, hardness, toughness with the comprehensive performance, but also can be combined with one or more special properties, such as wear-resistant, high and low temperature resistance, corrosion resistance.