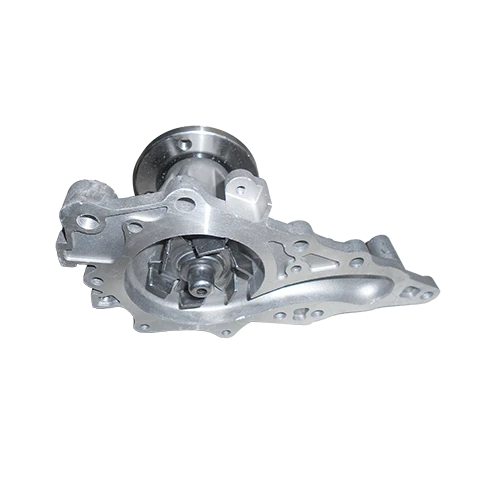

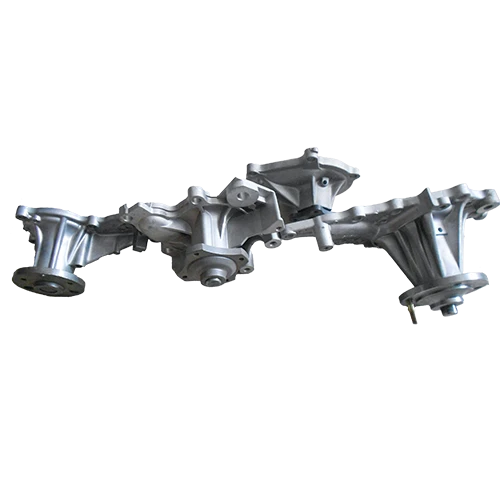

The casting method of automobile water pump shell mainly includes one-time casting molding method and die-casting process. Disposable casting molding method is suitable for one-time casting molding of complex structural products, by heating the upper and lower molds to 180-240 degrees, and then spraying material on the inner surface of the cavity formed after the mold is closed, and then heated to 300-350 degrees, and then installing the sand core in turn, and pouring liquid aluminum or liquid aluminum alloy through the pouring channel on the upper or lower molds. This method of molding products is simple, lightweight, low cost, and solves the casting and molding problems of many complex structures in one-piece structures1.

The die casting process is another common casting method used in the molding process of aluminum alloys for automobiles. Aluminum alloy has the advantage of weight reduction, energy saving and recycling, with the automotive parts increasingly lightweight, most of the automotive water pump using cast aluminum shell. Die casting process organization dense, surface quality and mechanical properties are better, is one of the most widely used process. Although die casting parts often have porosity and oxidation inclusions exist in the problem, but through the optimization of process design can improve its quality.

In summary, the casting method of automotive water pump shell includes one-time casting molding method and die casting process, the former is suitable for one-time molding of complex structure, the latter is widely used because of its excellent surface quality and mechanical properties.

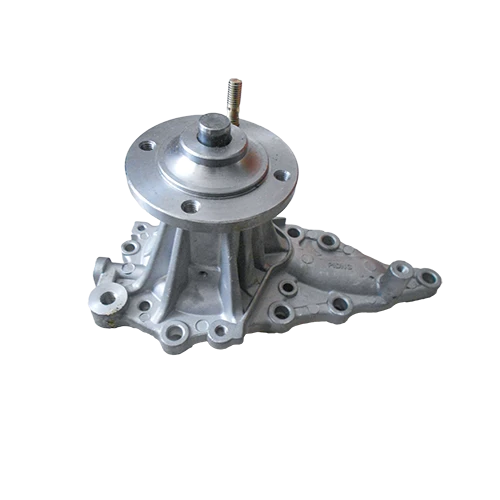

Automotive water pump preparation materials

A water pump bearing

- PTFE material water pump bearings: this material has good wear resistance, corrosion resistance and self-lubrication, widely used in automotive water pumps. 2.

- Ceramics material water pump bearings: this material has high hardness, high wear resistance and high corrosion resistance, in the high temperature and high pressure environment with good stability and durability.

- steel pump bearings: this material manufacturing process is simple, low cost and easy to process, widely used in general automotive water pump.

Second, mechanical seals

- graphite material mechanical seals: this material has good corrosion resistance and high temperature resistance, widely used in automotive water pumps. 2. rubber material mechanical seals: this material has good stability and durability.

- rubber material mechanical seal: this material has good sealing performance, and has good stability in the high temperature environment of automotive water pumps.

- metal oxide material mechanical seal: this material has high hardness and high wear resistance, and has good stability and durability in high temperature and high pressure environment.

Third, the impeller material

- aluminum alloy material impeller: this material manufacturing process is simple, low cost, but in the high temperature and high pressure environment is easy to deformation, not suitable for high temperature and high pressure environment.

- cast iron material impeller: this material has high heat resistance and high corrosion resistance, but more brittle, not impact resistance. 3. plastic material impeller: this material is not suitable for high temperature and high pressure environment.

- plastic material impeller: this material has good wear resistance and corrosion resistance, widely used in automobile water pump.

Fourth, the shell material

- aluminum alloy shell: this material is lightweight and easy to manufacture, but heat resistance is not strong enough for use in high temperature environments. 2. cast iron material shell: this material has good wear resistance and corrosion resistance, widely used in automotive water pumps.

2 cast iron material shell: this material has high strength, good corrosion resistance, widely used in automotive water pumps. 3 stainless steel material shell: this material has high strength, good corrosion resistance, widely used in automotive water pumps.

- stainless steel material shell: this material has excellent corrosion resistance, but the cost is higher, generally only in the advanced models or special models used.

In summary, automotive water pump preparation materials include water pump bearings, mechanical seals, impellers, shells, etc., each material has its own characteristics. In the actual application, it is necessary to choose the appropriate material according to the specific working environment and the type of car.