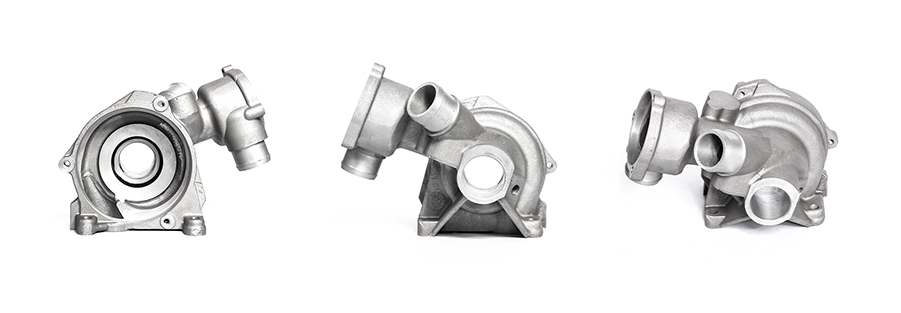

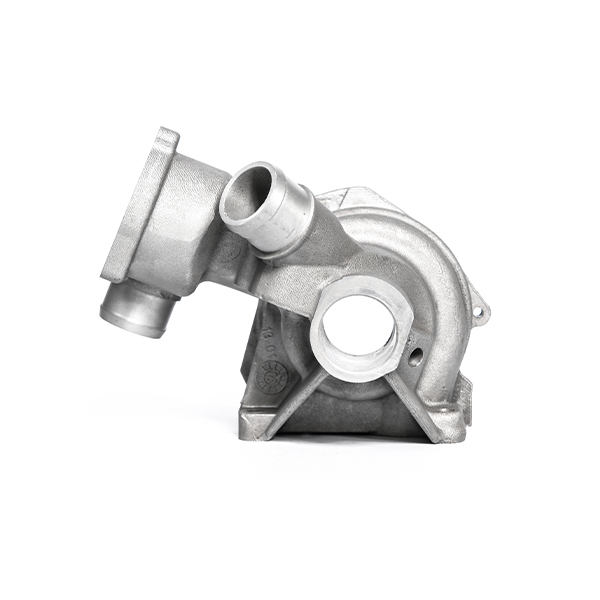

Products Description

Automotive water pump housing castings are an important part of automotive water pumps, usually made of aluminum alloy, cast iron and other materials. Water pump housing is an important part of the water pump, used to protect the internal parts of the pump and ensure the normal operation of the pump.

Casting is one of the common processes used to manufacture water pump housing, by injecting molten metal into the mold, to be cooled and solidified to form the shape of the shell. Casting process can produce complex shapes of parts, and has the advantages of low cost, high production efficiency.

The quality and design of automotive water pump housings play an important role in the performance and durability of automotive engines. Automobile manufacturers usually design and produce water pump housing castings according to the requirements of specific car models to ensure its compatibility and stability with the entire cooling system.

(1) Cast Iron Materials

Cast iron is the main material for traditional automotive water pumps. Cast iron has good rigidity and hardness, but also has good corrosion resistance. However, cast iron is heavy and not easy to mold.

(2) Cast steel material

Cast steel material is one of the more widely used materials. It has high strength and hardness, and also has good corrosion resistance. However, the cost of cast steel is high and it is not easy to mold.

(3) Aluminum Alloy Materials

Aluminum alloy material is one of the important materials in modern automobile production. It has light weight, high strength, good thermal conductivity and good corrosion resistance. Compared with cast iron and cast steel materials, aluminum alloy material has a lower cost and is also easier to form, so it is more widely used in the production of modern automotive water pumps.