Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Metal Castings: Precision, Fast Lead Times, ISO-Certified

pièces moulées en métal is a key solution in the manufacturing industry, specifically within foundries and Aluminum casting manufacturing. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- metal castings Overview

- Benefits & Use Cases of metal castings in Aluminum casting manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on metal castings from Welcome To Hebei Yuanda Trade Co., Ltd.

metal castings Overview

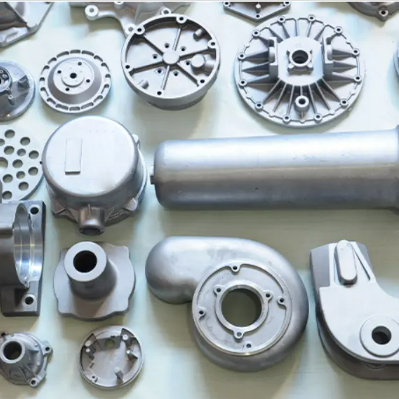

Metal castings are engineered components formed by pouring molten metal into a mold to achieve near-net shapes with repeatable precision. In Aluminum casting manufacturing and foundries, processes like aluminum die casting, permanent mold casting, and green sand metal casting are selected based on geometry, tolerances, mechanical requirements, and volume. Aluminum alloys such as A356, ADC12, and 6061 deliver an excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance—ideal for applications ranging from powertrain housings to industrial enclosures. When tight tolerances, fine surface finishes, or thin walls are critical, an expertly designed aluminum casting die can minimize machining and accelerate production.

Welcome To Hebei Yuanda Trade Co., Ltd. provides a robust portfolio of metal castings that serve OEMs and Tier suppliers in automotive, machinery, energy, and electronics. Backed by disciplined process control, simulation-driven tooling design, and thorough inspection (e.g., CMM, spectrographic analysis, and X-ray where required), Yuanda helps B2B decision makers de-risk launches and scale reliably. While aluminum leads in weight-sensitive designs, comparative materials such as stainless steel casting may be recommended for elevated temperature or high-corrosion environments, ensuring the right solution per use case.

Benefits & Use Cases of pièces moulées en métal in Aluminum casting manufacturing

In practice, aluminum metal casting enables complex geometries with integrated ribs, bosses, and channels—reducing part count and improving assembly efficiency. Typical applications include motor housings, gearbox covers, pump bodies, heat sinks, bracketry, and chassis components. For large runs, aluminum die casting offers high repeatability, tight dimensional control, and short cycle times. For mid-volume or larger components, permanent mold and green sand metal casting balance tooling cost with flexibility, making them excellent for industrial equipment and off-highway parts. Early involvement on the aluminum casting die design lets engineers optimize draft, fillets, and gating to reduce porosity and scrap.

Welcome To Hebei Yuanda Trade Co., Ltd. combines DFM feedback, rapid prototyping, and iterative tooling improvements to shorten PPAP timelines and stabilize production. Competitive advantages include reliable alloy selection for performance targets, process windows tuned for consistent mechanical properties, and an inspection plan aligned to critical-to-quality features. Whether you’re comparing die casting to machining from billet, or benchmarking against stainless steel casting for corrosive service, Yuanda’s application engineers help you quantify trade-offs in weight, cost, and durability for confident sourcing decisions.

Cost, Maintenance & User Experience

Total cost of ownership for metal castings is driven by tooling investment, alloy usage, cycle time, yield, and post-processing. Aluminum die casting typically has higher upfront die costs but offers compelling piece-price economics at scale through faster cycles and reduced machining. Green sand metal casting may provide lower tooling costs and greater size flexibility, beneficial for lower-volume programs. Optimizing the aluminum casting die for thermal balance and flow reduces defects and rework, directly improving ROI. Strategic finishing—such as heat treatment, shot blasting, impregnation, or coating—can extend service life and reduce warranty risk.

B2B customers report smoother launches when suppliers provide transparent APQP, capability studies, and traceability of heats and lots. Welcome To Hebei Yuanda Trade Co., Ltd. emphasizes proactive communication, clear inspection criteria, and stable logistics planning, which lowers the cost of quality across the program lifecycle. Practical maintenance recommendations—like scheduled die refurbishing, controlled melt practices, and consistent release agent application—help maintain dimensional stability and surface integrity, keeping your lines running and your parts within spec.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping metal castings. Aluminum’s high recyclability and favorable strength-to-weight ratio support light-weighting strategies in transportation, industrial machinery, and electrification. Foundries increasingly invest in efficient melting technologies, closed-loop sand reclamation, and water-based release systems to cut emissions and reduce waste. Buyers also evaluate supply partners on material traceability, recycled content, and conformance with regulations such as REACH and RoHS, along with emerging carbon disclosure requirements and customer-specific environmental standards.

Welcome To Hebei Yuanda Trade Co., Ltd. takes a forward-looking approach—leveraging design simulation to reduce trial iterations, promoting DFM that minimizes machining stock, and aligning process control to lower scrap. These practices improve both sustainability and cost performance. As the market trends toward nearshoring, shorter lead times, and quality analytics, Yuanda’s focus on robust planning and real-time feedback supports predictable delivery. Whether your roadmap includes aluminium metal casting for EV platforms or corrosion-resistant solutions comparing aluminum to stainless steel casting, partnering early ensures your specifications align with responsible, future-ready production.

Conclusion on metal castings from Welcome To Hebei Yuanda Trade Co., Ltd.

From concept to SOP, metal castings remain a cornerstone of modern manufacturing—especially in Aluminum casting manufacturing where speed, precision, and durability converge. Welcome To Hebei Yuanda Trade Co., Ltd. combines process expertise, disciplined quality, and application-driven engineering to deliver consistent results across die casting, permanent mold, and green sand routes. For B2B decision makers seeking reliable supply, optimized cost, and scalable performance, Yuanda is a capable partner. Contact us: email: info@ydcastings.com. Visit our website: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNouvellesNov.24,2025

-

Material Properties of CF8M CastingNouvellesNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNouvellesNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNouvellesNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNouvellesNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNouvellesNov.21,2025