Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

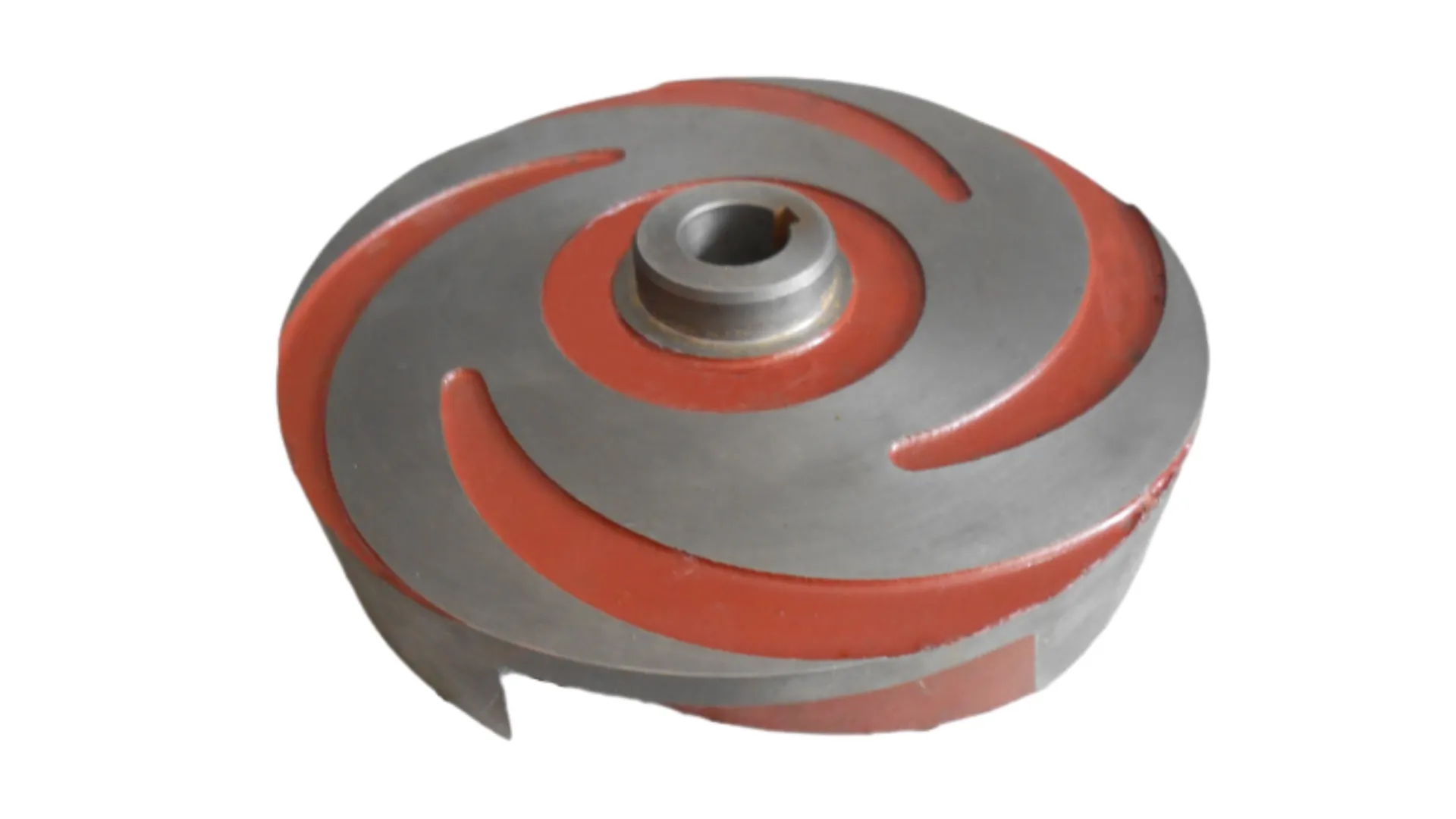

PRODUCT PARAMETERS

-

Material: stainless steel 316, 304, 17-4PH

-

Representative products: impeller

-

Thickness of fan blade 1.5-2.5mm

-

Fan blade height 2.5-5mm

-

Blank tolerance ISO8062-CT5-6

-

The internal structure of the impeller is generally composed of 7-11 individual blades. In order to achieve a certain flow rate, the blades are designed with a composite shape of rotation plus twist.

-

In addition, the impeller itself is a two-sided closed structure, which makes it more difficult to mold the internal blades in the production of the impeller. First of all, in the process of making wax type, the whole impeller can not be produced as a whole, and it is necessary for the process designers to make certain divisions according to the structure of the product, and then assembled and molded.

-

Secondly, in the process of making silica-sol shell, the narrow space of two cover plates of the impeller needs the shell-making agent to enter easily and completely wrap the wax shell, so as to ensure the strength of the cavity in the casting process. Finally, during the casting process, it is also ensured that the end of each fan blade is filled with liquid metal and there is no outgassing. After repeated process design discussions and summarized in the actual casting process. These problems have been solved one by one. At present, we produce impellers with complete and smooth runners and no internal defects after X-ray inspection.

Performance

-

Material performance: stainless steel impeller castings are made of stainless steel, which has excellent corrosion resistance, high temperature resistance and high strength and other properties. These properties enable the stainless steel impeller to be used in a variety of complex environments, such as high temperature and corrosive environments1.

-

Mechanical properties: stainless steel impeller castings are produced through the precision casting process, characterized by high precision and complex shapes. Its organization is uniform and dense, which ensures reliability and stability in use.

Advantage

-

CORROSION RESISTANCE: Stainless steel impellers can be used for a long time in harsh environments such as strong acids and alkalis without corrosion or rust. This makes the stainless steel impeller widely used in chemical, food, pharmaceutical and other fields.

-

High temperature resistance: stainless steel impeller is not easy to deform and fail under high temperature environment, which is suitable for high temperature process field. This makes the stainless steel impeller excel in industrial equipment that requires high temperature processing1.

-

Easy to clean: stainless steel impeller surface smooth, not easy to stain the dirt, easy to clean, can ensure the health and safety of the production process

Operation Scenario

-

Stainless steel impellers are suitable for a variety of industrial fields, including food, pharmaceutical, chemical and other industries, and can meet the production needs of different fields.

Contactez-nous

Hebei Yuanda Trade Co., Ltd.(YD) was founded in 2006, devoted itself to provide flexible solutions for different needs of customized metal castings.

-

Materials Used in Manufacturing Cap End Pipe Fittings2024-03-12Materials Used in Manufacturing Cap End Pipe Fittings

Materials Used in Manufacturing Cap End Pipe Fittings2024-03-12Materials Used in Manufacturing Cap End Pipe Fittings -

-

-

E-mail

-

WhatsApp

-

Haut