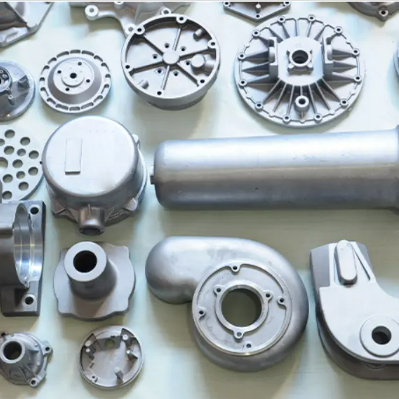

Die casting machine : 180tons – 2000 tons locking force

Material and grade : ADC-12, A380

Range of produce size : 10-1200mm

Range of weight : 0.1-15kg

Main products : Motor housing, Aluminum case, Auto parts, Bracket, Street light shell, LED lamp radiator, Motor junction box.

Capacity : Total 4 foundrys, 3000tons/year.

Aluminum castings are a popular choice in manufacturing due to their high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are used in a wide variety of applications, including automotive, aerospace, and consumer goods.

The process of producing aluminum castings typically involves melting aluminum alloys in a furnace and then pouring the molten metal into a mold. The mold is often made of sand, although other materials such as plaster or ceramic may also be used. Once the metal has cooled and solidified, the mold is removed and the casting is cleaned and finished as needed.

One of the advantages of aluminum casting is that it can be used to create complex shapes and geometries that may be difficult or impossible to produce using other manufacturing methods. It is also a cost-effective method for producing large quantities of parts.

Aluminum castings are a versatile and reliable option for many manufacturing applications, and can provide an excellent balance of strength, weight, and cost-effectiveness.