Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

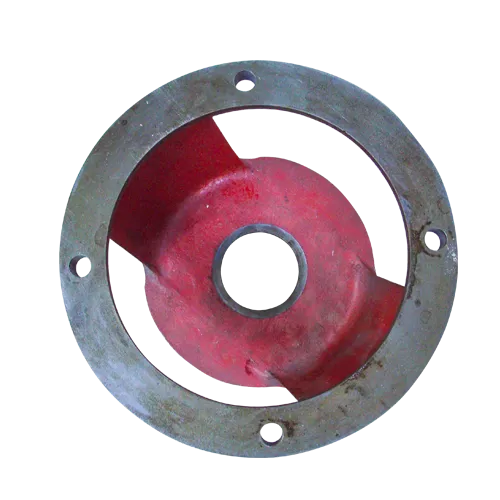

Impeller for Pumps – High-Efficiency, Durable, OEM-Ready

Impeller is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of pumps, valves, compressors, and similar machinery. This article explores how Welcome To Hebei Yuanda Trade Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Impeller Overview

- Benefits & Use Cases of Impeller in Manufacturing of pumps, valves, compressors, and similar machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Impeller from Welcome To Hebei Yuanda Trade Co., Ltd.

Impeller Overview

An impeller is the rotating heart of a pump, transferring mechanical energy into fluid energy to generate flow and head. Whether specified as a closed, semi-open, or open water pump impeller, the geometry, surface finish, metallurgy, and balance quality determine efficiency, reliability, and noise/vibration performance. For OEMs in the General equipment manufacturing industry and in Manufacturing of pumps, valves, compressors, and similar machinery, the right impeller on pump design is a primary lever for system efficiency and lifetime cost control. Typical specifications requested by B2B buyers include precision cast profiles, CNC-machined eye and keyway features, dynamic balancing to ISO 1940 (e.g., G6.3 or tighter on request), and tight concentricity for seamless integration with the pump casing and seal chamber.

Welcome To Hebei Yuanda Trade Co., Ltd. delivers foundry-to-finish capabilities for corrosion- and wear-resistant alloys (e.g., ductile iron, stainless such as CF8M/CF3M, duplex, bronze). Leveraging casting simulation, optimized gating, and rigorous inspection (CMM, pressure/leak testing when required), Yuanda helps OEMs achieve repeatable performance across product families. In addition to impellers, matched components such as pump casing parts, connector brackets, and cap ends can be produced under unified process control to simplify vendor management and speed qualification. The result: consistent hydraulic performance, higher yield, and a shorter path from drawing release to first-article approval.

Benefits & Use Cases of Impeller in Manufacturing of pumps, valves, compressors, and similar machinery

Impellers power mission-critical equipment across water and wastewater treatment, HVAC chillers, chemical and petrochemical processing, irrigation, firefighting, slurry handling, and booster systems. In each case, the impeller on pump determines the hydraulic signature—NPSH requirements, BEP efficiency, and tolerance to solids and cavitation. For water utilities, a precisely profiled water pump impeller reduces energy consumption and enhances reliability. In chemical service, duplex or austenitic stainless impellers resist chloride stress corrosion while maintaining tight clearances to minimize recirculation losses.

Welcome To Hebei Yuanda Trade Co., Ltd. supports OEMs with design-for-casting input, fast tooling turnarounds, and production scaling. Competitive advantages include smooth cast surfaces that reduce secondary machining, consistent vane-to-shroud thickness, and dynamic balance validated prior to shipment for drop-in assembly to the pump casing. Yuanda’s ability to co-produce related cast components—such as housings, brackets, and cap ends—gives procurement teams fewer interfaces and simplified logistics. This integrated approach helps engineering teams shorten validation cycles while ensuring that the impeller, shaft, seals, and casing mate precisely to deliver low vibration and high uptime in the field.

Cost, Maintenance & User Experience

Total cost of ownership for an impeller is driven by three factors: energy efficiency over the equipment life, durability in the operating medium, and maintenance intervals. Precision-cast, well-balanced impellers typically lower motor load, reduce bearing stress, and extend seal life—compounding savings across the rotating assembly. Choosing the right alloy and surface finish for the fluid (clean water, slurry, corrosive or abrasive media) can materially reduce erosion/corrosion and unplanned downtime. Many buyers see strong ROI when upgrading to higher-grade materials or tighter balance classes, especially in 24/7 duty cycles.

Field feedback from general equipment manufacturers points to consistent metallurgy and repeatable dimensions as top contributors to assembly speed and reduced rework. Users appreciate clear documentation, traceability, and inspection data accompanying each batch. Maintenance teams recommend periodic checks of running clearances, balance condition after rebuilds, and surface integrity at leading edges—practices that Yuanda’s manufacturing discipline supports with dimensional reports and finish control. By pairing the impeller with correctly machined pump casing and related components, customers streamline rebuilds and extend mean time between maintenance, reinforcing predictable lifecycle costs.

Sustainability & Market Trends in manufacturing

Energy efficiency and emissions reduction are reshaping the pump market. Regulations and buyer expectations—from Ecodesign directives to efficiency indices—push OEMs toward higher-performance hydraulics and optimized impeller profiles. On the manufacturing side, trends include increased recycled content in ferrous and stainless alloys, reclamation of foundry sand, and improved melting efficiency to reduce energy per casting. Digitalization is also accelerating: CAD/CAE-driven vane optimization, casting simulation to minimize defects, and automated inspection enable faster PPAP and fewer quality escapes.

Welcome To Hebei Yuanda Trade Co., Ltd. aligns with these priorities by emphasizing process control, first-pass yield, and material efficiency. By advising on alloy selection for longer wear life and by integrating casting and machining under one roof, Yuanda helps OEMs avoid over-processing, reduce scrap, and cut logistics emissions. The company’s forward-thinking approach—embracing simulation, data-driven quality, and collaborative engineering—supports customers’ sustainability roadmaps while delivering the dependable impeller performance that high-duty industrial applications demand.

Conclusion on Impeller from Welcome To Hebei Yuanda Trade Co., Ltd.

From clean water distribution to corrosive chemical handling, an engineered Impeller is central to performance, efficiency, and reliability. By uniting robust casting practices, precise machining, and verified balance, Welcome To Hebei Yuanda Trade Co., Ltd. delivers impellers—and related pump casing parts, brackets, and cap ends—that help B2B manufacturers reduce lifecycle costs and increase uptime. Partner with a supplier that understands your hydraulic, material, and production challenges. Contact us: email: info@ydcastings.com • Visit our website: https://www.ydcastings.com

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

-

Essential Insights on Plug End Caps for Industrial EquipmentNewsNov.21,2025

-

Quality Inspection of Valve BodyNewsNov.21,2025