Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Automobile Accessories-Hebei Yuanda Trade Co., Ltd.|High Pressure Casting&Semi-Solid Processing

Introduction to Automotive Metal Casting Technologies

The automotive industry relies heavily on metal casting and processing technologies to produce high-performance components that meet stringent quality and efficiency standards. As vehicle manufacturers strive for lighter, more durable, and environmentally friendly solutions, the development of advanced casting methods has become critical. This article delves into the key technologies shaping modern automotive accessory production, including automobile accessories, die casting, semi-solid processing, and integrated design approaches.

1. Casting Technology: Foundation of Automotive Manufacturing

Casting is a fundamental process in automotive part production, accounting for 15-20% of all components. This method is particularly vital for creating power system key components and structural parts. Developed nations like the United States and European countries have advanced casting technologies that ensure high-quality products with minimal environmental impact.

Key Advantages of Modern Casting Technology

- High Production Efficiency: Digital technologies enhance process design, reducing scrap rates to 2-5%.

- Environmental Sustainability: Advanced systems minimize pollution and resource waste.

- Polyvalence des matériaux : Capable of handling various alloys, including aluminum and zinc.

While China's casting output is significant, there remains a gap in technical sophistication compared to global leaders. National Institute of Standards and Technology (NIST) research highlights the importance of adopting digital twins and predictive modeling to bridge this gap, as noted in their 2023 report on manufacturing innovation.

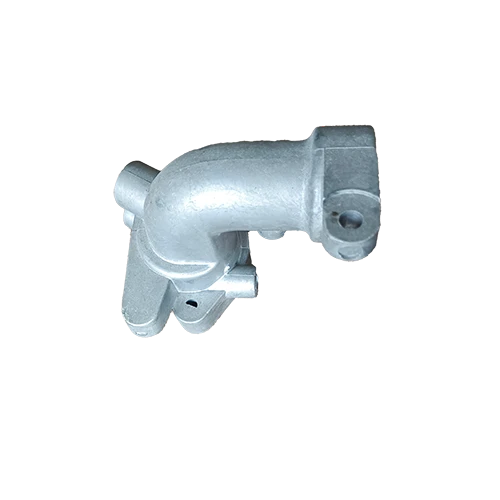

2. Die Casting: Precision and Performance in Automotive Components

Die casting plays a pivotal role in modern automotive manufacturing by using high pressure to shape molten metal into precise forms. This technique ensures dimensional accuracy and surface quality, critical for vehicle stability and performance. The process utilizes alloys like aluminum and zinc, which offer exceptional strength and durability.

Applications of Die Casting

- Engine Components: Cylinder heads, blocks, and transmission cases.

- Structural Parts: Chassis and suspension components.

- Electrical Systems: Automotive electric water pumps and other electrical housings.

The die casting process has evolved significantly, with NIST standards guiding the development of high-precision molds and real-time monitoring systems. These advancements have reduced defects and improved consistency in production.

3. Semi-Solid Processing: A New Era in Magnesium Alloy Casting

Semi-solid processing represents a breakthrough in producing lightweight, high-strength components. This technology is particularly effective for magnesium and aluminum alloys, addressing traditional challenges in die-casting magnesium alloys. It enables thinner walls (1-1.5mm) and improved mold design flexibility.

Key Benefits of Semi-Solid Processing

- Weight Reduction: Magnesium alloys are 30% lighter than aluminum, contributing to fuel efficiency.

- High Strength-to-Weight Ratio: Ideal for structural components requiring durability.

- Thermal Stability: Resistant to high temperatures and corrosion.

According to NIST studies, semi-solid processing has seen a 25% annual growth rate in the U.S. automotive sector, driven by demand for eco-friendly materials. This technology aligns with global trends toward sustainable manufacturing.

4. Integrated Design: Optimizing Automotive Components

Integrated design is a growing trend in automotive manufacturing, focusing on reducing weight and production costs through structural optimization. By creating single-piece components, manufacturers can eliminate unnecessary machining processes and enhance performance.

Advantages of Integrated Design

- Lightweight Solutions: Reduced material usage without compromising strength.

- Cost Efficiency: Streamlined production processes lower overhead.

- Improved Performance: Enhanced fit and function of components.

This approach is particularly relevant for automobile accessories like engine manifolds and water pumps, where precision and durability are paramount.

5. Product Specifications: Technical Details of Automotive Accessories

| Material | Process | Specification | Weight Range |

|---|---|---|---|

| ADC-12, A380 | High-Pressure Casting | Customizable | 0.5-2kg |

6. Company Background: Hebei Yuanda Trade Co., Ltd.

As a leading manufacturer in the automotive industry, Hebei Yuanda Trade Co., Ltd. specializes in producing high-quality automobile accessories using advanced casting technologies. The company's commitment to innovation and sustainability ensures that its products meet international standards.

Key Strengths of Hebei Yuanda

- Technical Expertise: Skilled in die casting, semi-solid processing, and integrated design.

- Quality Assurance: Adherence to strict manufacturing protocols.

- Global Reach: Exporting products to markets worldwide.

7. Applications of Advanced Casting Technologies

The technologies discussed have broad applications in the automotive sector, including:

- Powertrain Components: Engine blocks, transmission cases, and gear housings.

- Electrical Systems: Automotive electric water pumps and control units.

- Structural Parts: Chassis components and suspension systems.

These innovations not only enhance vehicle performance but also support the industry's shift toward electric and hybrid vehicles, where lightweight and efficient components are essential.

8. Conclusion: The Future of Automotive Manufacturing

The continuous evolution of metal casting and processing technologies is reshaping the automotive industry. By embracing advanced techniques like die casting, semi-solid processing, and integrated design, manufacturers can achieve higher efficiency, sustainability, and performance. Hebei Yuanda Trade Co., Ltd. exemplifies how innovation and quality can drive success in this dynamic field.

References

NIST (National Institute of Standards and Technology): "Manufacturing Innovation and Digital Transformation," 2023. https://www.nist.gov/

Hebei Yuanda Trade Co., Ltd.: https://www.ydcastings.com

-

Materials Used in Manufacturing Cap End Pipe FittingsNouvellesNov.24,2025

-

Material Properties of CF8M CastingNouvellesNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNouvellesNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNouvellesNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNouvellesNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNouvellesNov.21,2025