Mobile:+86-311-808-126-83

E-mail:info@ydcastings.com

Automobile Accessories - Hebei Yuanda Trade Co., Ltd. | Advanced Metal Casting & Die Casting

Automobile accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of this industry. As automotive manufacturers strive for lightweight, high-performance components, advancements in casting techniques have become essential. This article explores the latest developments in automotive metal casting technologies, their advantages, technical specifications, and applications, while highlighting the expertise of Hebei Yuanda Trade Co., Ltd., a leading supplier of automotive parts.

Evolution of Automotive Metal Casting Technologies

The automotive industry has long relied on metal casting to produce critical components. According to NIST (National Institute of Standards and Technology) research, casting accounts for approximately 15-20% of all automotive parts, with significant emphasis on powertrain and structural components. Advanced casting technologies have evolved to meet demands for higher efficiency, reduced environmental impact, and improved product quality.

Casting Technology: Precision and Quality

Casting technology remains a cornerstone of automotive manufacturing. In developed countries like the United States and European nations, casting processes are highly advanced, achieving a scrap rate of 2-5% through digital design optimization. These technologies enable the production of high-precision components with exceptional dimensional accuracy and surface quality.

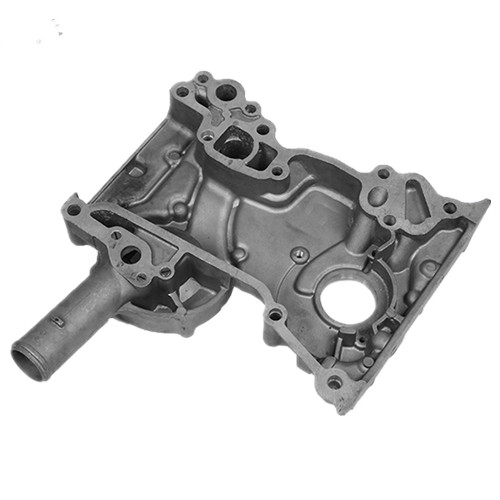

Hebei Yuanda Trade Co., Ltd. leverages cutting-edge casting methods to deliver components such as automotive electric water pumps and engine manifolds, which are critical for vehicle performance and durability. The company’s use of ADC-12 and A380 aluminum alloys ensures optimal strength-to-weight ratios, aligning with global industry standards.

Die Casting: Enabling High-Performance Components

Die casting is a pivotal process in modern automotive manufacturing, utilizing high-pressure metal injection to create complex, precise parts. This method is particularly effective for producing components like electric water pumps and auto electric water pumps. The use of aluminum and zinc alloys in die casting enhances the strength, durability, and corrosion resistance of automotive parts.

According to NIST studies, die casting has enabled significant improvements in vehicle stability and performance by ensuring tight tolerances and surface finish. Hebei Yuanda Trade Co., Ltd. employs this technology to manufacture lightweight, high-performance accessories that meet the rigorous demands of the automotive industry.

Semi-Solid Processing: A Breakthrough in Magnesium Alloy Casting

Semi-solid processing technology has emerged as a game-changer for producing magnesium alloy components. This method addresses traditional challenges in die-casting magnesium alloys, such as poor mechanical properties and high costs. By achieving a casting wall thickness of 1-1.5 mm and a mold slope of 1°-2°, semi-solid processing enables the creation of lightweight, high-strength parts.

As noted in NIST reports, the automotive industry is increasingly adopting magnesium alloys due to their superior strength-to-weight ratio, heat resistance, and corrosion resistance. Hebei Yuanda Trade Co., Ltd. utilizes this technology to produce components that contribute to vehicle weight reduction, enhancing fuel efficiency and safety.

Integrated Design: The Future of Automotive Manufacturing

Integrated design is becoming a key trend in automotive manufacturing, driven by the need for energy efficiency, environmental sustainability, and cost reduction. By optimizing part structures and reducing machining processes, integrated casting techniques help achieve lightweight, high-performance components.

Hebei Yuanda Trade Co., Ltd. specializes in integrated design solutions, offering products like automotive electric water pumps that are engineered for seamless integration into vehicle systems. This approach not only reduces production costs but also enhances the overall performance and reliability of automotive accessories.

Technical Specifications of Automotive Accessories

| Product | Material | Process | Weight Range |

|---|---|---|---|

| Automotive Electric Water Pump | ADC-12, A380 | High-Pressure Casting | 0.5-2 kg |

| Engine Manifolds | ADC-12, A380 | High-Pressure Casting | 0.5-2 kg |

Applications of Advanced Casting Technologies

The advancements in metal casting and processing technologies have enabled the production of a wide range of automotive accessories, including:

- Automotive Electric Water Pumps: Essential for cooling systems, these components ensure optimal engine performance.

- Engine Manifolds: Critical for air and fuel distribution, they enhance engine efficiency.

- Auto Electric Water Pumps: Used in hybrid and electric vehicles, these pumps contribute to thermal management systems.

About Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer of automotive accessories, specializing in high-quality metal casting and processing solutions. With a commitment to innovation and excellence, the company provides reliable products that meet international standards. Their expertise in advanced casting technologies ensures that automotive parts are lightweight, durable, and performance-driven.

For more information about their products and services, visit Hebei Yuanda Trade Co., Ltd..

Conclusion

The automotive industry is undergoing a transformation driven by advancements in metal casting and processing technologies. From traditional casting methods to semi-solid processing and integrated design, these innovations are shaping the future of automotive manufacturing. Hebei Yuanda Trade Co., Ltd. exemplifies the commitment to quality and innovation, offering cutting-edge solutions that meet the evolving needs of the industry.

As the demand for lightweight, high-performance components continues to grow, the role of advanced casting technologies will only become more critical. By leveraging these technologies, automotive manufacturers can achieve greater efficiency, sustainability, and competitiveness in the global market.

References

National Institute of Standards and Technology (NIST) - Research on casting technologies and automotive manufacturing standards.

-

Materials Used in Manufacturing Cap End Pipe FittingsNouvellesNov.24,2025

-

Material Properties of CF8M CastingNouvellesNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNouvellesNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNouvellesNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNouvellesNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNouvellesNov.21,2025

Automobile Accessories - Hebei Yuanda Trade Co., Ltd. | Advanced Metal Casting & Die Casting

Automobile accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of this industry. As automotive manufacturers strive for lightweight, high-performance components, advancements in casting techniques have become essential. This article explores the latest developments in automotive metal casting technologies, their advantages, technical specifications, and applications, while highlighting the expertise of Hebei Yuanda Trade Co., Ltd., a leading supplier of automotive parts.

Evolution of Automotive Metal Casting Technologies

The automotive industry has long relied on metal casting to produce critical components. According to NIST (National Institute of Standards and Technology) research, casting accounts for approximately 15-20% of all automotive parts, with significant emphasis on powertrain and structural components. Advanced casting technologies have evolved to meet demands for higher efficiency, reduced environmental impact, and improved product quality.

Casting Technology: Precision and Quality

Casting technology remains a cornerstone of automotive manufacturing. In developed countries like the United States and European nations, casting processes are highly advanced, achieving a scrap rate of 2-5% through digital design optimization. These technologies enable the production of high-precision components with exceptional dimensional accuracy and surface quality.

Hebei Yuanda Trade Co., Ltd. leverages cutting-edge casting methods to deliver components such as automotive electric water pumps and engine manifolds, which are critical for vehicle performance and durability. The company’s use of ADC-12 and A380 aluminum alloys ensures optimal strength-to-weight ratios, aligning with global industry standards.

Die Casting: Enabling High-Performance Components

Die casting is a pivotal process in modern automotive manufacturing, utilizing high-pressure metal injection to create complex, precise parts. This method is particularly effective for producing components like electric water pumps and auto electric water pumps. The use of aluminum and zinc alloys in die casting enhances the strength, durability, and corrosion resistance of automotive parts.

According to NIST studies, die casting has enabled significant improvements in vehicle stability and performance by ensuring tight tolerances and surface finish. Hebei Yuanda Trade Co., Ltd. employs this technology to manufacture lightweight, high-performance accessories that meet the rigorous demands of the automotive industry.

Semi-Solid Processing: A Breakthrough in Magnesium Alloy Casting

Semi-solid processing technology has emerged as a game-changer for producing magnesium alloy components. This method addresses traditional challenges in die-casting magnesium alloys, such as poor mechanical properties and high costs. By achieving a casting wall thickness of 1-1.5 mm and a mold slope of 1°-2°, semi-solid processing enables the creation of lightweight, high-strength parts.

As noted in NIST reports, the automotive industry is increasingly adopting magnesium alloys due to their superior strength-to-weight ratio, heat resistance, and corrosion resistance. Hebei Yuanda Trade Co., Ltd. utilizes this technology to produce components that contribute to vehicle weight reduction, enhancing fuel efficiency and safety.

Integrated Design: The Future of Automotive Manufacturing

Integrated design is becoming a key trend in automotive manufacturing, driven by the need for energy efficiency, environmental sustainability, and cost reduction. By optimizing part structures and reducing machining processes, integrated casting techniques help achieve lightweight, high-performance components.

Hebei Yuanda Trade Co., Ltd. specializes in integrated design solutions, offering products like automotive electric water pumps that are engineered for seamless integration into vehicle systems. This approach not only reduces production costs but also enhances the overall performance and reliability of automotive accessories.

Technical Specifications of Automotive Accessories

| Product | Material | Process | Weight Range |

|---|---|---|---|

| Automotive Electric Water Pump | ADC-12, A380 | High-Pressure Casting | 0.5-2 kg |

| Engine Manifolds | ADC-12, A380 | High-Pressure Casting | 0.5-2 kg |

Applications of Advanced Casting Technologies

The advancements in metal casting and processing technologies have enabled the production of a wide range of automotive accessories, including:

- Automotive Electric Water Pumps: Essential for cooling systems, these components ensure optimal engine performance.

- Engine Manifolds: Critical for air and fuel distribution, they enhance engine efficiency.

- Auto Electric Water Pumps: Used in hybrid and electric vehicles, these pumps contribute to thermal management systems.

About Hebei Yuanda Trade Co., Ltd.

Hebei Yuanda Trade Co., Ltd. is a leading manufacturer of automotive accessories, specializing in high-quality metal casting and processing solutions. With a commitment to innovation and excellence, the company provides reliable products that meet international standards. Their expertise in advanced casting technologies ensures that automotive parts are lightweight, durable, and performance-driven.

For more information about their products and services, visit Hebei Yuanda Trade Co., Ltd..

Conclusion

The automotive industry is undergoing a transformation driven by advancements in metal casting and processing technologies. From traditional casting methods to semi-solid processing and integrated design, these innovations are shaping the future of automotive manufacturing. Hebei Yuanda Trade Co., Ltd. exemplifies the commitment to quality and innovation, offering cutting-edge solutions that meet the evolving needs of the industry.

As the demand for lightweight, high-performance components continues to grow, the role of advanced casting technologies will only become more critical. By leveraging these technologies, automotive manufacturers can achieve greater efficiency, sustainability, and competitiveness in the global market.

References

National Institute of Standards and Technology (NIST) - Research on casting technologies and automotive manufacturing standards.

-

Materials Used in Manufacturing Cap End Pipe FittingsNouvellesNov.24,2025

-

Material Properties of CF8M CastingNouvellesNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNouvellesNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNouvellesNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNouvellesNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNouvellesNov.21,2025