-

First, the industry briefly Die casting, as an important metal moldingMehr lesen

First, the industry briefly Die casting, as an important metal moldingMehr lesen -

In the context of global economic integration, the foundry industry as the basis of manufacMehr lesen

In the context of global economic integration, the foundry industry as the basis of manufacMehr lesen -

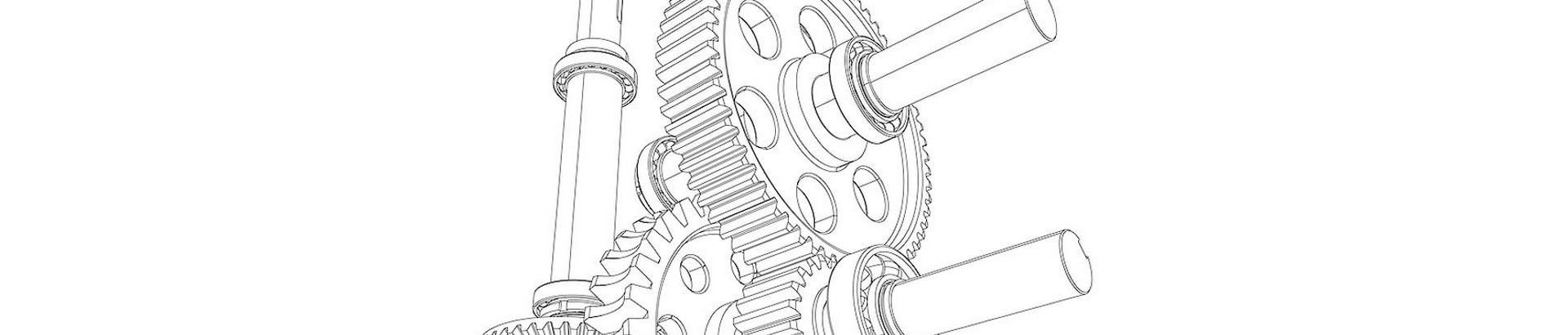

Gear reducers – more commonly known as gearboxes – are among the most commonplace and critical components of any complex motor. The gear reducer controls the output from a motor, adjusting the speed and torque of the power by sending it through a series of gears.Mehr lesen

Gear reducers – more commonly known as gearboxes – are among the most commonplace and critical components of any complex motor. The gear reducer controls the output from a motor, adjusting the speed and torque of the power by sending it through a series of gears.Mehr lesen -

The gearbox has the function of deceleration. Compared with ordinary gears, it has the advantages of a large reduction ratio and compact installation position.Mehr lesen

The gearbox has the function of deceleration. Compared with ordinary gears, it has the advantages of a large reduction ratio and compact installation position.Mehr lesen -

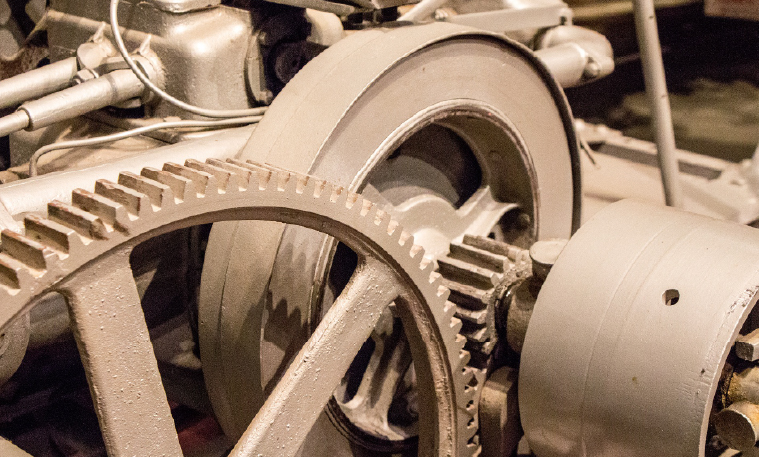

Fitted in locations such as steel mills, mining operations, and wind turbines, they are often exposed to arduous conditions including extremes of temperature, humidity, vibration, and contamination, often with little maintenance.Mehr lesen

Fitted in locations such as steel mills, mining operations, and wind turbines, they are often exposed to arduous conditions including extremes of temperature, humidity, vibration, and contamination, often with little maintenance.Mehr lesen -

A gearbox has many components, all of which play an important role to ensure proper functioning. Before we examine these components, let’s start by defining what a gearbox is.Mehr lesen

A gearbox has many components, all of which play an important role to ensure proper functioning. Before we examine these components, let’s start by defining what a gearbox is.Mehr lesen -

An industrial gearbox is an enclosed system that transmits mechanical energy to an output device. Gearboxes can modify their speed, torque, and other attributes to convert the energy into a useable format.Mehr lesen

An industrial gearbox is an enclosed system that transmits mechanical energy to an output device. Gearboxes can modify their speed, torque, and other attributes to convert the energy into a useable format.Mehr lesen -

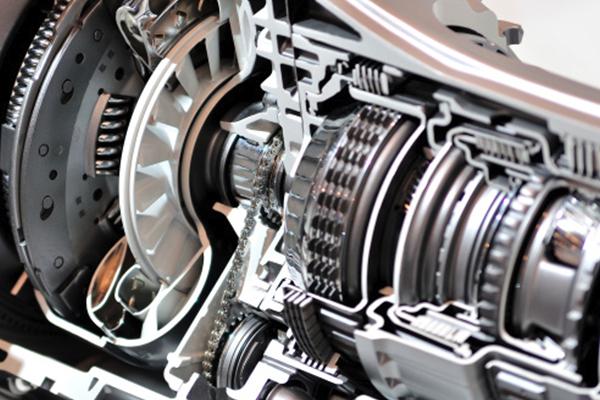

The gearbox is a set of gears essential to the movement of the vehicle. These gears are made up of sprockets that, connected to each other, create the “strength” to start the gear and keep the vehicle moving.Mehr lesen

The gearbox is a set of gears essential to the movement of the vehicle. These gears are made up of sprockets that, connected to each other, create the “strength” to start the gear and keep the vehicle moving.Mehr lesen -

I don’t think there’s anyone oblivious of the primary function of a gearbox in a car. Can you imagine a car without a gearbox? It would be slow, unstable, and incredibly noisy. Plus, you may not be aware that a gearbox stabilises the engine.Mehr lesen

I don’t think there’s anyone oblivious of the primary function of a gearbox in a car. Can you imagine a car without a gearbox? It would be slow, unstable, and incredibly noisy. Plus, you may not be aware that a gearbox stabilises the engine.Mehr lesen -

You know what is the gearbox and what are the types of the gearbox? No, so let’s know what is this gearbox and How does a gearbox work and What is the main function of the gearbox?Mehr lesen

You know what is the gearbox and what are the types of the gearbox? No, so let’s know what is this gearbox and How does a gearbox work and What is the main function of the gearbox?Mehr lesen -

Based on the application requirements and design specifications, choose appropriate material of industrial gearbox. Consider factors such as Load Capacity, Fatigue Strength, wear resistance, Temperature Stability,Manufacturing and Cost Considerations,and corrosion resistance.Mehr lesen

Based on the application requirements and design specifications, choose appropriate material of industrial gearbox. Consider factors such as Load Capacity, Fatigue Strength, wear resistance, Temperature Stability,Manufacturing and Cost Considerations,and corrosion resistance.Mehr lesen -

Machines over a period of time go through a lot of wear and tear. The gearbox is the heart and soul for any machine to keep running. To ensure its longevity, regular maintenance and servicing is a must.Mehr lesen

Machines over a period of time go through a lot of wear and tear. The gearbox is the heart and soul for any machine to keep running. To ensure its longevity, regular maintenance and servicing is a must.Mehr lesen

Handy, Mobiltelefon:+86-311-808-126-83

Email:info@ydcastings.com