Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 09, 2025 11:31

Back to list

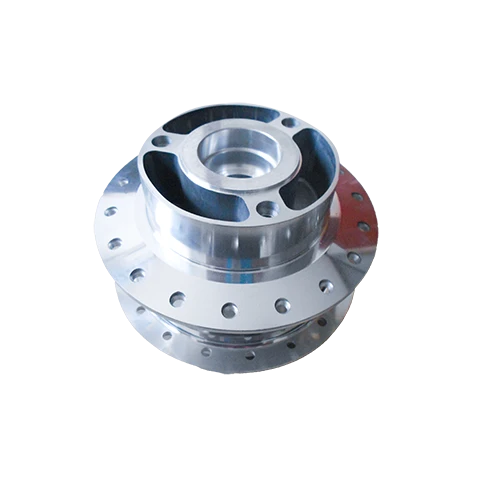

water pump impeller

When it comes to enhancing the efficiency and longevity of water pumps, the design and quality of the water pump impeller are paramount. This crucial component governs the mechanism that moves water through the pump, translating rotational energy into the fluid’s movement. For anyone looking to optimize their water pumps for various applications, understanding the intricacies of impeller technology is essential.

Authoritative studies and technical papers often highlight the significance of balancing and precision machining in manufacturing impellers. Proper balance of the impeller reduces vibration, which is vital for maintaining operational stability and noise reduction. This precision engineering not only ensures smooth operation but also substantiates the equipment's compliance with international performance standards, a factor that solidifies the impeller as a reliable part of any pump system. Trustworthiness hinges on a product's proven effectiveness and durability over time. The reputation of manufacturers specializing in water pump impellers reflects their commitment to quality and innovation. Companies that invest in comprehensive quality control and rigorous testing protocols provide consumers with assurance that their impellers will perform optimally under specified conditions. Testimonials and case studies from industrial applications further establish confidence in the product, demonstrating real-world successes and reliability. In conclusion, the water pump impeller is a fundamental component that significantly impacts the overall performance of water pumps. By leveraging advanced materials, innovative designs, and precise engineering, these impellers not only enhance pump efficiency but also contribute to operational cost savings through reduced maintenance and extended equipment life. When choosing an impeller, it is crucial to consider application-specific requirements and opt for products from reputable manufacturers that stand behind their quality with robust warranties and after-sales support. This informed selection will ensure that your water pumping system remains efficient, reliable, and durable across its operational lifespan.

Authoritative studies and technical papers often highlight the significance of balancing and precision machining in manufacturing impellers. Proper balance of the impeller reduces vibration, which is vital for maintaining operational stability and noise reduction. This precision engineering not only ensures smooth operation but also substantiates the equipment's compliance with international performance standards, a factor that solidifies the impeller as a reliable part of any pump system. Trustworthiness hinges on a product's proven effectiveness and durability over time. The reputation of manufacturers specializing in water pump impellers reflects their commitment to quality and innovation. Companies that invest in comprehensive quality control and rigorous testing protocols provide consumers with assurance that their impellers will perform optimally under specified conditions. Testimonials and case studies from industrial applications further establish confidence in the product, demonstrating real-world successes and reliability. In conclusion, the water pump impeller is a fundamental component that significantly impacts the overall performance of water pumps. By leveraging advanced materials, innovative designs, and precise engineering, these impellers not only enhance pump efficiency but also contribute to operational cost savings through reduced maintenance and extended equipment life. When choosing an impeller, it is crucial to consider application-specific requirements and opt for products from reputable manufacturers that stand behind their quality with robust warranties and after-sales support. This informed selection will ensure that your water pumping system remains efficient, reliable, and durable across its operational lifespan.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS