Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Top Aluminum Die Casting Suppliers for High-Quality Components and Reliable Manufacturing Solutions Worldwide

The Role of Aluminum Die Casting Suppliers in Modern Manufacturing

In today’s fast-paced manufacturing environment, companies are constantly on the lookout for efficient, cost-effective materials that can enhance their production processes. Aluminum die casting has emerged as a vital solution for numerous industries, thanks to its unique properties such as lightweight, corrosion resistance, and excellent structural integrity. As demand for aluminum die casting components continues to grow, the role of aluminum die casting suppliers has become increasingly important.

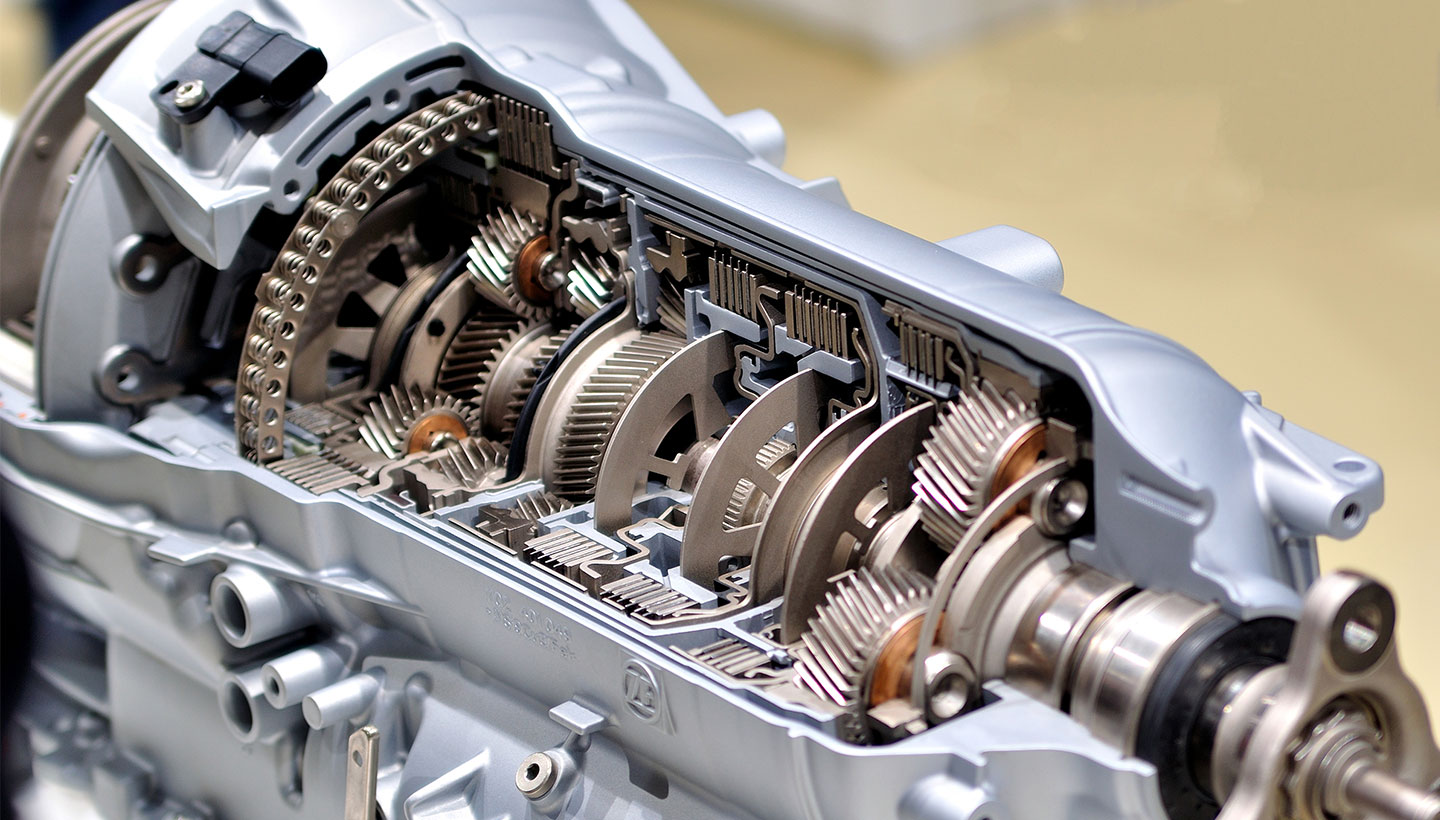

Aluminum die casting is a process that involves injecting molten aluminum alloy into a mold at high pressure. This technique produces parts with exceptional dimensional accuracy, allowing them to be used in a wide array of applications—from automotive to consumer electronics. The lightweight nature of aluminum makes it an ideal choice for industries looking to reduce weight while maintaining strength and durability.

Aluminum die casting suppliers serve as crucial partners in this manufacturing process. They are responsible for providing high-quality materials, advanced technology, and expert support to manufacturers. The selection of a reliable aluminum die casting supplier can significantly impact the overall production quality, timelines, and cost-effectiveness.

One of the key factors that distinguishes a good aluminum die casting supplier is their ability to offer a range of aluminum alloys. Different applications require specific alloys that can withstand varying degrees of stress and environmental conditions. A knowledgeable supplier can guide manufacturers in choosing the right alloy, ensuring optimal performance for the intended application.

aluminum die casting supplier

Moreover, state-of-the-art technology is a hallmark of reputable aluminum die casting suppliers. With advancements in die casting processes and machinery, suppliers can provide precision-engineered components that meet the stringent requirements of modern manufacturing. Many suppliers now employ computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to enhance the design and production processes. This results in faster lead times and higher quality parts while reducing waste.

In addition to materials and technology, a reliable aluminum die casting supplier will offer value-added services, including prototyping, finishing, and assembly. By providing comprehensive solutions, suppliers help streamline the manufacturing process, allowing clients to focus on their core competencies. This integrated approach can lead to significant cost savings and increased efficiency.

Quality assurance is another critical aspect of a competent aluminum die casting supplier. Ensuring that components meet industry standards and customer specifications is paramount. Suppliers that follow rigorous quality control processes, including testing and inspection, can guarantee the reliability and performance of their products. This is increasingly important in industries such as aerospace and automotive, where safety and durability are non-negotiable.

Sustainability is also becoming a significant consideration for manufacturers. As more companies prioritize eco-friendly practices, aluminum die casting suppliers are responding by adopting more sustainable processes. Aluminum itself is 100% recyclable, and many suppliers are now implementing recycling programs and energy-efficient production techniques. This not only helps reduce the environmental footprint but also appeals to consumers who are increasingly discerning about sustainability.

In conclusion, aluminum die casting suppliers play a pivotal role in modern manufacturing. Their expertise in materials, technology, and quality assurance ensures that manufacturers can produce high-quality, efficient products that meet evolving market demands. By partnering with a reliable supplier, companies can enhance their production capabilities, drive innovation, and ultimately achieve greater success in their respective industries. As the demand for aluminum die casting continues to grow, the importance of selecting the right supplier cannot be overstated.

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025