Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

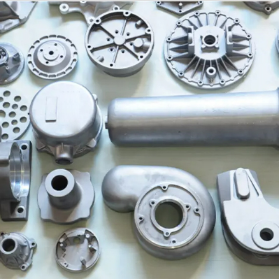

Superior Aluminum Castings in Automotive Engine Parts

Superior aluminum castings have revolutionized the automotive industry, offering a perfect blend of strength, lightweight properties, and durability that is essential for modern engine performance. From cylinder heads to intake manifolds, aluminum castings play a pivotal role in enhancing fuel efficiency, reducing emissions, and improving overall engine reliability. Hebei Yuanda Trade Co., Ltd. (YD), founded in 2006, specializes in providing flexible solutions for customized metal castings, including high-quality aluminum castings for various automotive engine components. With their expertise in precision casting, YD ensures that each piece meets the stringent standards required for automotive applications, whether it’s a small part or large aluminum castings for heavy-duty engine systems.

Advantages of Superior Aluminum Castings in Engine Parts

- Lightweight Design: One of the most significant benefits of superior aluminum castingsis their low density compared to traditional materials like cast iron. This reduces the overall weight of the engine, which in turn improves fuel efficiency and lowers carbon emissions. For example, replacing a cast iron cylinder block with an aluminum one can cut engine weight by up to 50%, making it a key factor in meeting modern automotive sustainability goals.

- Excellent Thermal Conductivity: Aluminum castings dissipate heat more efficiently than many other metals, helping to keep engine components cool during operation. This is crucial for parts like cylinder heads and water pumps, which are exposed to high temperatures. Efficient heat management prevents overheating, extends component lifespan, and maintains optimal engine performance even under strenuous conditions.

- Design Flexibility: The casting process for superior aluminum castingsallows for complex shapes and intricate designs that are difficult to achieve with other materials. This flexibility enables engineers to create engine parts with optimized airflow, reduced weight, and enhanced functionality. Whether it’s a precisely contoured intake manifold or a multi - port cylinder head, aluminum casting supports the innovation needed for high-performance engines.

Types of Aluminum Castings Used in Automotive Engines

- Die-Cast Aluminum Parts: Die casting is ideal for producing high - volume, intricate aluminum castingslike valve covers and oil pans. The process involves forcing molten aluminum into a steel mold under high pressure, resulting in parts with tight tolerances and smooth surfaces. Hebei Yuanda Trade Co., Ltd. utilizes advanced die - casting techniques to ensure consistency and quality in these critical components.

- Sand-Cast Aluminum Components: Sand casting is suitable for large aluminum castingssuch as engine blocks and transmission cases. This method uses sand molds to shape molten aluminum, allowing for the production of large, complex parts with thick walls. Sand - cast superior aluminum castings offer excellent strength and durability, making them a reliable choice for heavy - duty engine components.

- Permanent Mold Castings: Permanent mold casting uses reusable metal molds to create parts with high dimensional accuracy and good surface finish. This process is often used for parts like cylinder heads and intake manifolds, where precision and performance are paramount. The resulting aluminum castingshave uniform structures, reducing the risk of defects and ensuring consistent performance.

Applications of Large Aluminum Castings in Automotive Engines

- Engine Blocks: Large aluminum castingsfor engine blocks are a staple in modern automotive design. They replace heavier cast iron blocks, reducing vehicle weight while maintaining the structural integrity needed to withstand combustion pressures. These blocks often feature integrated coolant passages and mounting points, showcasing the design flexibility of superior aluminum castings.

- Transmission Housings: Transmission housings made from large aluminum castingsprotect internal gears and components while providing structural support. Their lightweight nature reduces drivetrain inertia, improving shifting efficiency and overall vehicle performance. Hebei Yuanda’s expertise in casting large parts ensures these housings meet the strict strength and durability requirements of automotive transmissions.

- Suspension Components: Some high-performance vehicles use large aluminum castingsfor suspension parts like control arms and knuckles. These parts benefit from aluminum’s strength - to - weight ratio, enhancing handling and reducing unsprung weight for a smoother ride.

Quality Control Measures for Superior Aluminum Castings

- Material Testing: Before casting, aluminum alloys are tested for chemical composition and mechanical properties to ensure they meet the specifications for superior aluminum castings. This includes checks for tensile strength, hardness, and corrosion resistance, ensuring the material can withstand the demands of automotive engine operation.

- Dimensional Inspection: Using advanced tools like coordinate measuring machines (CMMs), manufacturers like Hebei Yuanda Trade Co., Ltd. verify that aluminum castingsmeet precise dimensional tolerances. This is critical for ensuring parts fit together correctly in the engine, preventing leaks, vibrations, or performance issues.

- Non-Destructive Testing: Techniques like X - ray inspection and ultrasonic testing are used to detect internal defects in large aluminum castingsthat may not be visible to the naked eye. These tests ensure that even hidden flaws are identified and addressed, maintaining the quality and reliability of the final product.

|

Quality Control Measure |

Purpose |

Relevant Aluminum Castings |

|

Material Testing |

Verify alloy composition and mechanical properties |

All superior aluminum castings |

|

Dimensional Inspection |

Ensure parts meet size and tolerance requirements |

Die - cast and permanent mold castings |

|

Non-Destructive Testing |

Detect internal defects |

Large aluminum castings like engine blocks |

Aluminum Castings FAQS

Why Are Superior Aluminum Castings Preferred Over Cast Iron in Modern Engines?

Superior aluminum castings offer a lighter weight, better thermal conductivity, and improved fuel efficiency compared to cast iron. While cast iron is stronger in some aspects, aluminum’s overall benefits align better with modern automotive goals of reducing emissions and enhancing performance.

How Do Large Aluminum Castings Maintain Their Strength Under Engine Stress?

Large aluminum castings achieve strength through alloying (adding elements like silicon or copper) and heat treatment, which enhance their mechanical properties. Advanced casting techniques, such as those used by Hebei Yuanda Trade Co., Ltd., also ensure uniform material structure, allowing them to withstand the stresses of engine operation.

Can Aluminum Castings Withstand High Engine Temperatures?

Yes. Aluminum castings used in engines are made from heat - resistant alloys that can handle temperatures up to 300°C or higher. Their excellent thermal conductivity also helps dissipate heat, preventing damage from overheating in critical components like cylinder heads.

What Makes Hebei Yuanda’s Aluminum Castings Superior?

Hebei Yuanda Trade Co., Ltd. uses high - quality aluminum alloys and advanced casting processes to produce superior aluminum castings. Their strict quality control measures, from material testing to dimensional inspection, ensure each part meets automotive industry standards for performance and reliability.

Are Large Aluminum Castings More Expensive Than Smaller Ones?

Large aluminum castings can be more costly due to the larger amount of material used and the complexity of their production. However, their long - term benefits—such as reduced vehicle weight and improved fuel efficiency—often offset the initial cost, making them a cost - effective choice for automotive manufacturers.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025