Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Expert Stainless Steel Casting | Precision & Durable Metal Parts

Navigating the Dynamics of Modern Industrial Components: Trends and Innovations

The industrial landscape is continuously evolving, driven by demands for increased efficiency, durability, and performance. In this context, material selection and manufacturing processes are paramount. For critical applications demanding exceptional resistance to corrosion, extreme temperatures, and mechanical stress, stainless steel casting emerges as a cornerstone technology. This advanced manufacturing method allows for the creation of complex, high-integrity components essential across a multitude of sectors.

Current industry trends highlight a growing reliance on advanced metal forming techniques. While `aluminum die casting` offers lightweight solutions for specific needs and `green sand metal casting` remains vital for high-volume, cost-effective parts, the demand for precision `metal castings` with superior material properties is on an upward trajectory. This shift is fueled by the need for components that can withstand increasingly harsh operating environments and contribute to longer service life and reduced maintenance in complex systems. The global market for high-performance `aluminium metal casting` and stainless steel components is projected to expand significantly, with stainless steel leading in applications where corrosion resistance and strength are non-negotiable.

Innovations in metallurgy and casting technologies are further enhancing the capabilities of cast components, pushing the boundaries of what is achievable in terms of intricate geometries and tighter tolerances. This article delves into the technical intricacies, vast applications, and strategic advantages of this critical manufacturing process, providing insights for B2B decision-makers and engineers seeking optimal material solutions.

The Precision of Stainless Steel Casting: Detailed Process Flow

The manufacturing process for stainless steel casting is a sophisticated sequence of steps designed to produce components with exceptional dimensional accuracy, surface finish, and mechanical integrity. Unlike simpler methods such as `green sand metal casting`, investment casting (or lost-wax casting) is predominantly used for stainless steel to achieve its required precision.

Process Stages:

- Pattern Creation (Wax Injection): A master die, often precision-machined from aluminum, is used to inject wax, creating an exact replica (pattern) of the desired component. Multiple patterns are typically assembled onto a central wax sprue to form a "tree."

- Shell Building (Refractory Coating): The wax tree is repeatedly dipped into a ceramic slurry and then stuccoed with refractory particles, followed by drying cycles. This forms a robust ceramic shell around the wax pattern. This process builds up layers until the shell is strong enough to withstand molten metal.

- Dewaxing: The ceramic shell, with the wax pattern inside, is heated in an autoclave or flash furnace. The wax melts and drains away, leaving a hollow ceramic mold. This step is critical for avoiding mold cracking and ensuring the cavity replicates the desired part.

- Firing: The dewaxed ceramic shell is fired at high temperatures (typically 800-1100°C) to burn out any residual wax, increase the mold's strength, and preheat it for casting. Preheating prevents thermal shock when the molten metal is poured.

- Melting and Pouring: High-quality stainless steel alloys (e.g., 304, 316, 17-4PH) are melted in an induction furnace under controlled atmospheric conditions to prevent oxidation. The molten metal is then poured into the hot ceramic mold. The specific grade of stainless steel is chosen based on the application's material requirements, such as corrosion resistance, strength, and weldability.

- Cooling and Solidification: The metal cools and solidifies within the mold, replicating the intricate shape of the original wax pattern.

- Knockout: Once sufficiently cooled, the ceramic shell is broken away from the metal casting using vibratory hammers or water blasting.

- Cut-off and Gate Removal: Individual castings are separated from the central sprue using cutting tools, abrasive wheels, or saws.

- Finishing Operations: This includes grinding to remove gate stubs, sandblasting for surface uniformity, and potentially heat treatment (e.g., solution annealing, precipitation hardening) to achieve desired mechanical properties. CNC machining may be employed for tight tolerance features, threads, or critical mating surfaces that cannot be achieved by casting alone.

- Inspection and Testing: Comprehensive quality control includes visual inspection, dimensional checks, non-destructive testing (NDT) like X-ray, liquid penetrant inspection, or magnetic particle inspection. Material composition is verified using spectroscopy, and mechanical properties are tested (tensile, hardness, impact). Products must meet rigorous standards such as ISO 9001:2015 for quality management and relevant ANSI or ASTM material specifications.

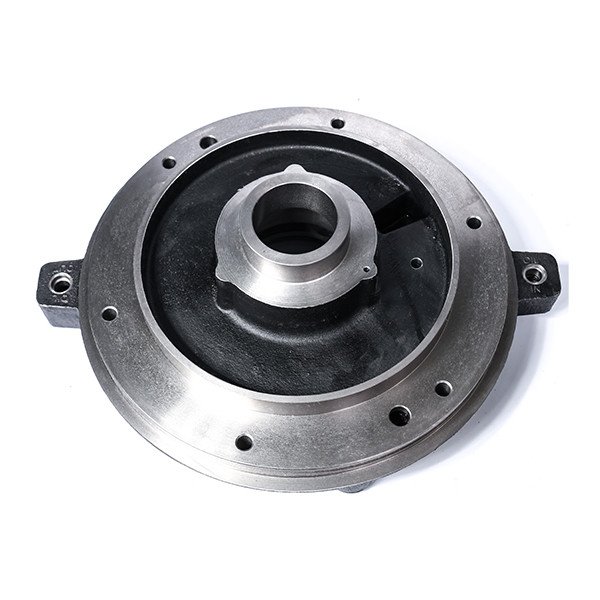

This meticulous process ensures that parts like the Cooling Flange Lower or Bearing Housing Lower achieve the required integrity and service life in demanding environments, offering superior corrosion resistance and energy-saving performance due to their optimized designs and material properties.

Technical Specifications & Performance Parameters of Stainless Steel Castings

The inherent properties of stainless steel, combined with the precision of the casting process, result in components with outstanding performance characteristics. Understanding these technical specifications is crucial for engineers and procurement specialists when selecting materials for demanding applications. Key parameters include mechanical strength, corrosion resistance, and thermal stability, which dictate the service life and reliability of the final product.

Typical Stainless Steel Casting Properties (e.g., ASTM A743/A744 Grades)

These specifications underscore the versatility of stainless steel casting across various grades. For instance, austenitic grades like CF8M (equivalent to 316L wrought stainless steel) offer superior corrosion resistance, particularly in chloride-rich environments, making them ideal for marine or chemical processing applications. Martensitic grades like CA6NM provide exceptional strength and hardness, suitable for hydro-turbine components or valve bodies requiring high wear resistance.

The service life of a well-engineered stainless steel casting component, manufactured to ISO 9001 and specific ASTM/ANSI standards, can extend for decades, significantly reducing total cost of ownership compared to materials with lesser resistance to operational stresses. This longevity is a key advantage in industries where downtime is costly, and reliability is paramount.

Application Scenarios & Target Industries

The robust properties of stainless steel casting make it indispensable across a diverse range of critical industries. Its unparalleled corrosion resistance, high strength at elevated temperatures, and hygienic properties open doors to applications where other `metal castings` would fail.

Key Industries and Applications:

- Petrochemical and Chemical Processing: Components exposed to aggressive chemicals, high pressures, and extreme temperatures, such as valve bodies, pump housings, flanges (e.g., Cooling Flange Lower), pipe fittings, and impellers. The resistance to stress corrosion cracking is critical here.

- Metallurgy and Heavy Industry: Parts for high-temperature furnaces, annealing lines, and material handling equipment, where heat and abrasive wear are common.

- Water Supply & Drainage: Essential for pumps, valves, flow meters, and other infrastructure components that are constantly exposed to water and potential corrosion from various water chemistries.

- Food & Beverage Processing: Strict hygiene requirements necessitate stainless steel for components like mixing impellers, conveyor parts, and food-contact surfaces due to its ease of cleaning and resistance to bacterial growth.

- Marine and Offshore: Parts for marine engines, propellers, hydraulic systems, and structural components that must withstand saltwater corrosion, making it superior to `aluminium metal casting` in such environments.

- Medical and Pharmaceutical: Surgical instruments, prosthetic components, and pharmaceutical processing equipment rely on the biocompatibility and sterilizability of stainless steel.

- Power Generation: Turbine components, heat exchanger parts, and critical fittings in conventional and nuclear power plants, where high temperatures and pressures are standard.

In typical application scenarios, the advantages are palpable. For a Cooling Flange Lower in a petrochemical plant, stainless steel casting ensures excellent corrosion resistance against aggressive coolants and process fluids, directly contributing to energy saving by maintaining system integrity and preventing leaks that would lead to efficiency losses. Similarly, a Bearing Housing Lower in a heavy industrial pump benefits from the high strength and wear resistance, extending operational life and reducing the frequency of costly maintenance interventions. These components exemplify how precise engineering with stainless steel directly impacts operational efficiency and long-term cost savings.

Unlocking Superior Performance: Technical Advantages of Stainless Steel Casting

Compared to alternative manufacturing methods and materials, stainless steel casting offers a distinct set of technical advantages that make it the preferred choice for demanding B2B applications. These benefits translate directly into enhanced product performance, increased operational reliability, and reduced lifecycle costs.

Core Advantages:

- Exceptional Corrosion Resistance: Stainless steel’s inherent chromium content forms a passive oxide layer, providing outstanding resistance to rust, pitting, crevice corrosion, and stress corrosion cracking in various aggressive environments, including acids, alkalis, and chlorides. This is a significant advantage over many other `metal castings`.

- High Strength and Durability: Stainless steel alloys offer high tensile strength, yield strength, and hardness, ensuring components can withstand heavy loads, abrasive wear, and impact without deformation or failure. This robust mechanical performance ensures a long service life.

- Excellent Heat Resistance: Many stainless steel grades retain their mechanical properties at elevated temperatures, making them suitable for high-temperature applications where other materials would soften or degrade.

- Design Flexibility and Intricate Geometries: Investment casting, the primary method for stainless steel, allows for the creation of highly complex and intricate geometries with thin walls, undercuts, and internal passages, reducing the need for extensive secondary machining. This provides designers with greater freedom compared to `aluminum casting die` which might have limitations on complexity.

- Superior Surface Finish: Investment castings typically achieve a smooth, aesthetically pleasing surface finish (Ra 3.2-6.3 µm) directly out of the mold, minimizing post-processing requirements.

- Cost-Effectiveness Over Lifecycle: While initial tooling costs might be higher than some alternative processes for low volumes, the extended service life, reduced maintenance, and superior performance of stainless steel components result in a lower total cost of ownership over the product's lifespan.

- Biocompatibility and Hygienic Properties: Certain grades are highly resistant to bacterial growth and are non-reactive, making them ideal for medical, pharmaceutical, and food processing applications, often mandated by FDA standards.

These advantages collectively position stainless steel casting as a premium solution for industries where performance, reliability, and longevity are paramount. By leveraging these technical benefits, businesses can significantly enhance the efficiency and safety of their operations.

Strategic Partner Selection: Vendor Comparison for Stainless Steel Casting

Choosing the right manufacturing partner for stainless steel casting is a strategic decision that directly impacts product quality, project timelines, and overall cost-efficiency. A thorough vendor comparison goes beyond pricing, focusing on capabilities, certifications, and a proven track record.

Key Criteria for Vendor Evaluation:

- Technical Expertise and Experience: Look for vendors with deep engineering knowledge in metallurgy, casting simulation, and post-casting processes like CNC machining and heat treatment. Experience with specific stainless steel grades and complex geometries is vital.

- Quality Management Systems: Adherence to international standards such as ISO 9001:2015 is non-negotiable. Certifications relevant to specific industries (e.g., PED for pressure equipment, FDA for medical) further demonstrate commitment to quality and authority.

- Capacity and Lead Time: Assess the vendor’s production capacity to meet your volume requirements and their ability to consistently deliver within agreed-upon lead times.

- Advanced Testing and Inspection Capabilities: A reputable vendor will have comprehensive in-house NDT (X-ray, MPI, LPI), chemical analysis (spectroscopy), and mechanical testing facilities to ensure product integrity.

- Customization and Design Support: The ability to offer tailored solutions, from design optimization to material selection, indicates a proactive and value-adding partner.

- Customer Support and Communication: Responsive communication and dedicated customer service are crucial for managing complex projects efficiently.

Comparative Overview of Casting Technologies and Vendor Capabilities:

While `aluminum die casting` excels in high-volume, lightweight applications, and `green sand metal casting` offers cost-effectiveness for less intricate parts, investment casting for stainless steel provides an unparalleled balance of precision, material integrity, and design flexibility, especially for critical components. Partnering with a specialized vendor ensures access to deep material science expertise and advanced manufacturing capabilities.

Tailored Solutions: Customized Stainless Steel Casting for Unique Requirements

In many advanced industrial applications, off-the-shelf components simply don't suffice. The ability to provide customized stainless steel casting solutions is a critical differentiator for leading manufacturers. This involves a collaborative process, from initial design concepts to final production, ensuring the component precisely meets unique operational demands.

Our Customization Process:

- Consultation and Design Collaboration: Our engineering team works closely with clients to understand specific application challenges, performance criteria, and environmental factors. This includes reviewing existing designs or developing new ones from scratch.

- Material Selection Expertise: Based on required corrosion resistance, strength, temperature ratings, and other parameters, we recommend the optimal stainless steel grade (e.g., 304, 316, duplex, super duplex, 17-4PH) to ensure peak performance and longevity.

- Advanced Simulation and Prototyping: Utilizing CAD/CAM software and casting simulation tools (e.g., MAGMAsoft, ProCAST), we analyze mold filling, solidification, and potential defects before physical production. This reduces development time and costs. Rapid prototyping may also be employed for functional testing.

- Tooling Design and Fabrication: Custom tooling (master dies) are precisely manufactured to achieve the exact dimensions and features of the designed component. This stage is crucial for the high dimensional accuracy intrinsic to investment casting.

- Integrated Manufacturing and Finishing: Beyond casting, we offer comprehensive post-casting services including precision CNC machining for critical interfaces, various heat treatments (e.g., solution annealing, precipitation hardening), surface finishing, and assembly, providing a complete solution.

- Rigorous Quality Assurance: Every customized component undergoes stringent inspection and testing, often tailored to client-specific requirements, to ensure it meets all specified technical parameters and quality standards.

Whether it's a unique Cooling Flange Lower with specialized mounting points or a custom Bearing Housing Lower designed for extreme load conditions, our approach ensures that clients receive components perfectly adapted to their system requirements. This flexibility and technical depth are critical for projects requiring precise functional integration and optimized performance in challenging industrial settings.

Real-World Impact: Stainless Steel Casting Application Case Studies

Demonstrating the tangible benefits of stainless steel casting through real-world examples is key to understanding its value. Our extensive experience in partnering with diverse industries showcases how tailored solutions can overcome complex engineering challenges and deliver significant operational advantages.

Case Study 1: Enhanced Performance for Cooling Flange Lower in Chemical Processing

- Client: A major chemical manufacturing corporation.

- Challenge: The client's existing cooling flange components, fabricated from a standard alloy, were experiencing premature failure due to severe corrosion and erosion from aggressive chemical coolants. Frequent replacements led to significant downtime and maintenance costs.

- Solution: We collaborated with the client to redesign the Cooling Flange Lower as a stainless steel casting, specifically utilizing ASTM CF8M (316L equivalent). The investment casting process allowed for precise internal geometry, optimizing flow dynamics and reducing cavitation, while the 316L grade offered superior resistance to chloride-induced corrosion and strong acids.

- Results: The new stainless steel flanges demonstrated a five-fold increase in service life, reducing component failure rates by 80%. This led to a 40% reduction in maintenance expenditures and prevented estimated annual production losses of over $500,000 due to unscheduled downtime. The client reported excellent satisfaction with the part's robust performance under continuous operation.

Case Study 2: Optimized Bearing Housing Lower for High-Load Industrial Pumps

- Client: A leading manufacturer of industrial pumps for water treatment facilities.

- Challenge: The original Bearing Housing Lower components were undergoing significant wear and tear due to heavy operational loads and exposure to abrasive particles in the pumped water. This led to premature bearing failure and compromised pump efficiency.

- Solution: We engineered a robust stainless steel casting solution using a duplex stainless steel grade (e.g., CD3MN / 2205 equivalent), known for its exceptional strength and superior wear resistance compared to standard austenitic grades. The casting design was optimized for improved structural integrity around the bearing seat, and critical dimensions were precisely CNC machined post-casting to ensure tight tolerances for bearing fitment.

- Results: The duplex stainless steel bearing housings exhibited a 200% improvement in lifespan, dramatically reducing bearing failures and subsequent pump maintenance. The client noted a measurable increase in pump uptime and efficiency, enhancing their product's reputation for reliability. This upgrade resulted in substantial savings for end-users, underscoring the long-term value of high-quality `metal castings`.

These cases exemplify how strategic material selection and advanced manufacturing in stainless steel casting can directly translate into tangible operational improvements, cost reductions, and enhanced product reliability, fulfilling the most demanding B2B requirements.

Ensuring Trust and Reliability: Our Commitment to Clients

At the core of our operations is a steadfast commitment to delivering exceptional quality, reliability, and client satisfaction. We understand that in the B2B sector, trustworthiness is built on consistent performance, clear communication, and robust support systems. Our adherence to stringent quality standards like ISO 9001 and partnership with clients across various regulated industries underscores our authoritative position in the industry, backed by years of service and extensive test data.

Frequently Asked Questions (FAQ)

Q: What are the typical lead times for custom stainless steel castings?

A: Lead times vary depending on the complexity of the part, chosen stainless steel grade, and required post-processing. For new projects involving tooling, initial samples typically take 6-10 weeks. Repeat orders for established designs can be fulfilled within 3-5 weeks, depending on order size and current production load. We work closely with clients to establish realistic timelines and communicate progress transparently.

Q: What warranty do you offer on your stainless steel castings?

A: We provide a comprehensive warranty against manufacturing defects and material non-conformity. Our components are guaranteed to meet or exceed all agreed-upon specifications and relevant industry standards (e.g., ASTM, ANSI). Specific warranty terms are outlined in our sales agreements and typically cover a period of 12-24 months from the date of shipment, subject to proper installation and usage.

Q: How do you ensure the quality of your metal castings?

A: Our quality assurance program is rigorous and multi-faceted. It includes strict material incoming inspection, in-process quality checks at every stage of the `stainless steel casting` process, comprehensive final inspection, and robust documentation. We utilize advanced testing methods such as chemical analysis (spectrometry), mechanical testing (tensile, hardness, impact), and non-destructive testing (X-ray, ultrasonic, magnetic particle, liquid penetrant inspection) to ensure every component meets the highest standards.

Q: Can you handle urgent orders or expedited shipping?

A: We understand that urgent needs can arise. While standard lead times apply, we are often able to accommodate expedited requests depending on current production schedules and material availability. Please contact our sales team to discuss your specific requirements, and we will do our utmost to provide a solution.

Lead Time & Fulfillment Details:

Our robust supply chain management and efficient production planning enable us to offer competitive lead times. We maintain inventory of common stainless steel grades and utilize lean manufacturing principles to optimize throughput. All orders are carefully packaged and shipped via trusted logistics partners to ensure timely and safe delivery.

Customer Support and After-Sales Service:

Our commitment extends beyond delivery. We offer dedicated technical support to assist with installation, troubleshooting, and any performance-related queries. Our responsive team is available via phone, email, and online portals to ensure continuous operational efficiency for your systems. We value long-term partnerships and are committed to providing unparalleled support throughout the lifecycle of our components.

Conclusion: The Enduring Value of Stainless Steel Casting

In an industrial landscape that prioritizes durability, precision, and long-term value, stainless steel casting stands out as an indispensable manufacturing solution. Its unique combination of corrosion resistance, mechanical strength, thermal stability, and design flexibility positions it as the superior choice for a myriad of critical applications across petrochemical, marine, water treatment, and food processing industries.

By leveraging advanced investment casting techniques, rigorous quality control, and an unyielding commitment to engineering excellence, manufacturers can deliver components like the Cooling Flange Lower and Bearing Housing Lower that not only meet but exceed the most demanding performance requirements. As industries continue to evolve, the strategic adoption of high-quality stainless steel castings will remain a cornerstone for achieving operational efficiency, reducing maintenance overheads, and ensuring sustained reliability.

References:

- ASM Handbook, Volume 15: Casting. ASM International, 2008.

- Stainless Steels for Design Engineers. J. R. Davis (Ed.). ASM International, 2008.

- ASTM A743/A743M, Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion-Resistant, for General Application. ASTM International, 2021.

- ISO 9001:2015, Quality management systems – Requirements. International Organization for Standardization, 2015.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025