Mobile:+86-311-808-126-83

Email:info@ydcastings.com

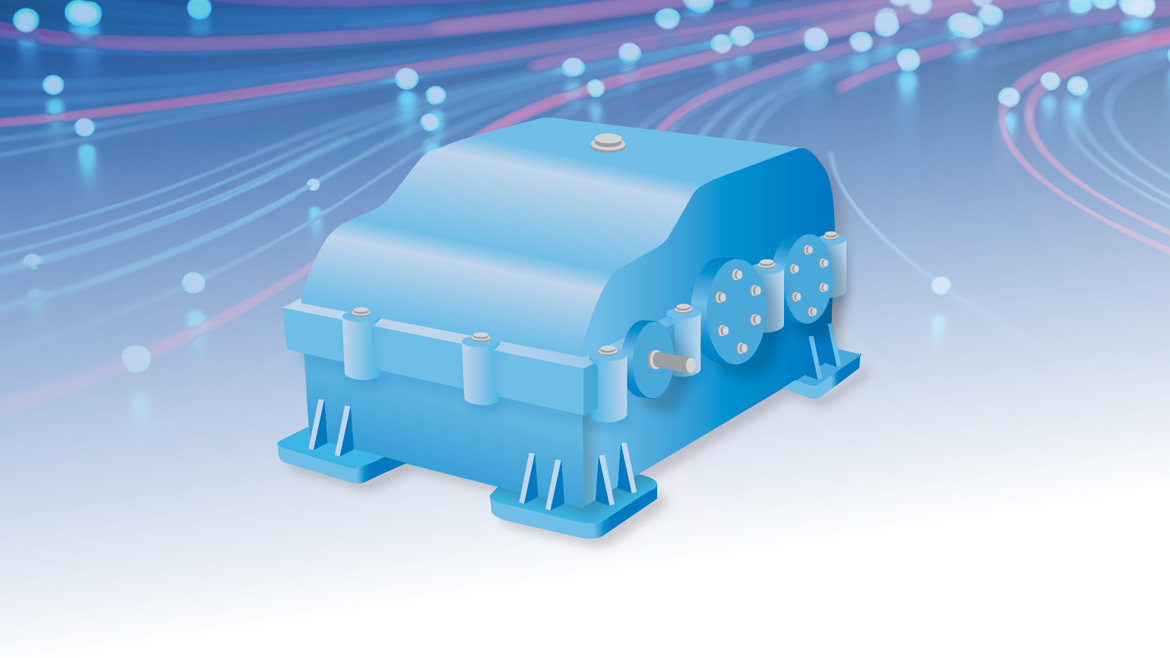

horizontal split casing

Horizontal Split Casing An Overview

In the world of engineering and manufacturing, the design and configuration of equipment play a critical role in determining efficiency, maintenance, and overall performance. One such configuration gaining prominence across various industries is the horizontal split casing. This design approach is particularly prevalent in the construction of pumps, compressors, and turbines. This article delves into the horizontal split casing concept, discussing its advantages, applications, and implications for different sectors.

Understanding Horizontal Split Casing

A horizontal split casing equipment is one that features a casing split horizontally, allowing the two halves of the casing to be separated along a horizontal plane. This design not only affects the assembly process but significantly impacts maintenance, operation, and performance characteristics. The split design allows easy access to the internal components of the equipment, making repairs and inspections straightforward.

In contrast to vertical split casings, horizontal designs offer several advantages, particularly in terms of space and accessibility. The horizontal orientation enables easier alignment of rotating shafts, which can lead to enhanced performance and reduced wear on mechanical components.

Advantages of Horizontal Split Casing

1. Ease of Maintenance One of the most significant benefits of horizontal split casings is the ease of access to internal components. Since the casing can be opened without removing the entire unit from its installation site, routine maintenance and inspections can be completed more efficiently. This can result in reduced downtime and lower maintenance costs.

2. Improved Safety With horizontal split casings, technicians can safely access equipment without maneuvering around complex scaffolding or lifts, which are often necessary for vertical units. This design reduces the risk of accidents during maintenance.

3. Reduced Footprint Horizontal split casings can require less overall space compared to other designs, which is particularly beneficial in applications where space is limited. Their horizontal profile allows for more compact installations.

4. Versatility Horizontal split casings find applications in a variety of industries, including water treatment, petrochemical, mining, and HVAC systems. Their versatility is one of the reasons they are widely adopted by engineers.

horizontal split casing

5. Performance Efficiency The precision in alignment afforded by horizontal split designs can result in better performance, higher efficiency, and extended longevity of the equipment. This contributes to lower operational costs and enhanced production capabilities.

Applications in Various Industries

The applications of horizontal split casing technology are wide-ranging. In the water management sector, for instance, horizontal split casing pumps are often deployed for large-scale water transfer systems, irrigation, and drainage applications. Their ability to handle substantial fluid volumes makes them ideal for these tasks while ensuring ease of maintenance.

In the oil and gas industry, horizontal split casing pumps are utilized in upstream activities for well service operations, as well as downstream processes for refining and transportation. Their reliability and capacity to handle varying pressures and conditions make them a go-to choice for operators.

Additionally, in power generation, horizontal split casing turbines are commonly used to optimize energy conversion processes. Their design enables efficient fluid dynamics and improved mechanical performance, essential for maximizing output in power plants.

Challenges and Considerations

Despite their many advantages, horizontal split casings are not without challenges. The initial design and manufacturing processes can be intricate, requiring precise engineering to ensure optimal performance. Moreover, while the horizontal design facilitates maintenance, it may necessitate specific site configurations that can complicate installation.

Conclusion

Horizontal split casing technology represents a significant advancement in engineering design and fluid mechanics. With its critical advantages, including ease of maintenance, enhanced safety, versatility, and operational efficiency, this design is likely to continue gaining traction across various sectors. As industries continue to seek improvements in performance and cost-effectiveness, the horizontal split casing approach will undoubtedly play a pivotal role in shaping future equipment design and operational strategies.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025