Mobile:+86-311-808-126-83

Email:info@ydcastings.com

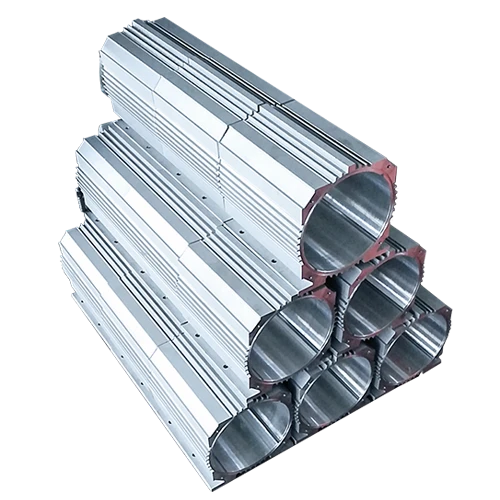

Achieving Superior Quality in Precision Castings for Industrial Applications

High Quality Castings The Backbone of Modern Manufacturing

In the pursuit of excellence in manufacturing, the importance of high-quality castings cannot be overstated. Castings form the foundation of numerous industries including automotive, aerospace, energy, and machinery. They are integral components that ensure the durability, efficiency, and functionality of various products. As technology advances and customer demands evolve, the standards for castings have also escalated, necessitating a focus on quality that transcends traditional methods.

High Quality Castings The Backbone of Modern Manufacturing

The casting process itself is another critical determinant of quality. There are various casting methods, including sand casting, die casting, investment casting, and more. Each technique has its inherent advantages and is suited for specific applications. For example, sand casting is favored for its versatility and cost-effectiveness, especially in producing large components. On the other hand, investment casting is prized for its ability to create intricate shapes with exceptional surface finishes. Selecting the appropriate casting method is vital in achieving high-quality outputs that meet the precise specifications and standards required in today’s competitive marketplace.

high quality castings

Quality assurance during the casting process plays a pivotal role in ensuring that the final product meets industry standards. This involves rigorous testing and inspection methods such as non-destructive testing (NDT), which helps identify any defects without damaging the component. Techniques like X-ray inspection, ultrasonic testing, and dye penetrant testing are commonly employed to ensure structural integrity and surface quality. Manufacturers must adhere to strict quality control protocols to minimize defects and enhance the reliability of the cast products.

Moreover, advancements in technology, particularly in the realm of digital manufacturing and automation, have revolutionized the casting industry. Computer-aided design (CAD) and computer-aided manufacturing (CAM) have facilitated the precise modeling and simulation of casting processes, allowing for optimized designs that minimize waste and improve quality. The introduction of 3D printing technology in creating molds and cores for casting is further pushing the boundaries of what is possible, allowing for more complex and lightweight designs that meet modern engineering demands.

Sustainability is also an increasingly significant consideration in the production of high-quality castings. Manufacturers are facing pressure to implement eco-friendly practices and reduce waste in their operations. Utilizing recycled materials for casting and adopting energy-efficient methods not only helps in meeting regulatory requirements but also resonates with environmentally conscious consumers. The move towards sustainability in casting practices is not just a trend; it represents a fundamental shift in the industry’s approach to resource management and production methodologies.

In conclusion, the essence of high-quality castings lies in the meticulous interplay of material selection, casting techniques, quality assurance, technological innovation, and sustainability practices. As industries continue to evolve, the need for high-quality castings will remain paramount. By committing to excellence at every stage of the manufacturing process, companies can produce castings that not only meet but exceed customer expectations, thereby securing their success in a competitive landscape. Ultimately, high-quality castings are not just components; they are the driving force behind innovation and progress in countless industries.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025