Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Flexible Rubber Connector for Efficient Pump Performance and Vibration Reduction

Understanding the Role of Pump Rubber Flex Connectors

In various industrial applications, especially in the field of fluid transfer systems, the importance of pump rubber flex connectors cannot be overstated. These connectors serve a critical function in ensuring efficient operation and longevity of the equipment involved. Let's dive into the significance of these components, their design, benefits, and some considerations for effective implementation.

What Are Pump Rubber Flex Connectors?

Pump rubber flex connectors are flexible joints made from high-quality rubber or elastomeric materials. They connect pipes, pumps, and other machinery in fluid transfer systems, allowing for movement and vibration dampening while maintaining a seal to prevent leaks. These connectors are designed to accommodate the thermal expansion and contraction of materials due to temperature fluctuations, as well as the vibrations generated during pump operation.

Why Are They Important?

One of the primary reasons for using rubber flex connectors in pump systems is their ability to absorb vibrations. Pumps, by their nature, generate vibrations as they operate, which can lead to wear and tear on connected equipment over time. Without proper isolation, these vibrations can cause equipment failures, misalignments, and eventual breakdowns. Rubber flex connectors mitigate these vibrations, enhancing the durability of the overall system.

Moreover, these connectors help in handling misalignments that may occur between the pumping equipment and the piping system. Whether due to installation errors, thermal expansion, or ground settling, misalignments can place undue stress on pipes and pumps, leading to potential failures. The flexibility of rubber connectors allows them to adjust to minor misalignments, ensuring smooth operation.

Benefits of Using Rubber Flex Connectors

1. Vibration Absorption As mentioned, one of the primary functions of rubber flex connectors is to absorb vibrations, which prolongs the life of pumps and connected equipment.

2. Flexibility The inherent flexibility of rubber allows these connectors to accommodate slight misalignments and expansions without compromising the integrity of the seal.

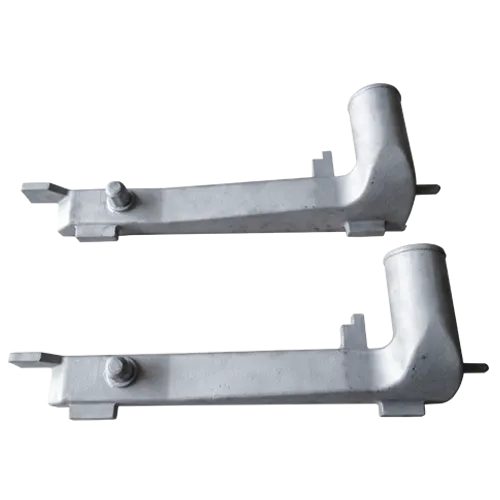

pump rubber flex connector

3. Leak Prevention Quality rubber connectors provide a tight seal that reduces the risk of leaks. This is particularly critical in systems handling hazardous or costly fluids.

4. Ease of Installation Rubber flex connectors are generally lighter and easier to handle than rigid pipe connections, simplifying installation and reducing labor costs.

5. Corrosion Resistance Many rubber compounds are resistant to chemicals and corrosion, making them suitable for various applications, including those involving corrosive substances.

Considerations for Implementation

When selecting pump rubber flex connectors, several factors should be taken into account

- Material Compatibility Ensure the rubber material is suitable for the application and compatible with the fluids being transferred to prevent degradation. - Pressure and Temperature Ratings Choose connectors that can handle the specific pressure and temperature ranges of your system to ensure reliability.

- Size and Dimensions Proper sizing is crucial to maintaining effective flow and preventing unnecessary stress on the system.

- Installation Practices Pay attention to installation guidelines to ensure optimal performance. Misalignments during installation can negate the benefits of using flex connectors.

Conclusion

In summary, pump rubber flex connectors are essential components in fluid transfer systems that improve performance, longevity, and efficiency. They provide the flexibility needed to handle vibrations and misalignments, reduce the risk of leaks, and simplify installation. For industries relying on pumping systems, understanding and utilizing these connectors effectively can lead to significant operational benefits and reduced maintenance costs. As technology advances, ongoing innovations in materials and designs will continue to enhance the functionality of these vital components.

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025