Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Exploring the Dynamics of Engine Chambers and Their Impact on Performance and Efficiency

The Engine Chamber Heart of Mechanical Innovation

The engine chamber serves as a critical component in various types of machinery, particularly in vehicles, aircraft, and industrial machines. This enclosed space houses the engine itself, which is the driving force that converts fuel into mechanical energy. In essence, the engine chamber is where the magic happens—transforming the chemical energy stored in fuel into kinetic energy that powers our world.

Design and Structure

The design of an engine chamber is a testament to engineering prowess. Typically constructed from materials that can withstand high temperatures and pressures, the chamber must ensure optimal performance and safety. Components such as the cylinder block, oil pan, and head are meticulously engineered to create an environment conducive to combustion. Moreover, modern engine chambers often incorporate advanced technologies like turbocharging and intercooling to maximize efficiency and power output.

Functionality

At its core, the engine chamber functions through precise sequences of intake, compression, combustion, and exhaust—often referred to as the four-stroke cycle in internal combustion engines. During the intake stroke, air and fuel enter the chamber. The compression stroke follows, where the mixture is compressed to increase its temperature. When the spark plug ignites the compressed mixture during the combustion stroke, an explosion occurs, pushing the piston down and generating power. Finally, during the exhaust stroke, the spent gases are expelled from the chamber, making way for a new cycle.

Innovations and Technology

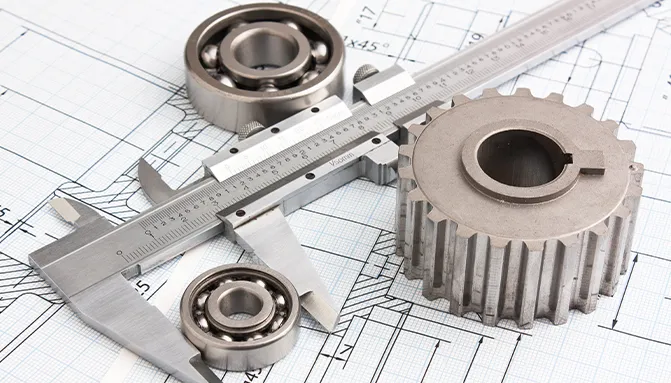

engine chamber

Over the years, innovations in engine chamber design and technology have transformed how engines operate. The advent of fuel injection systems, variable valve timing, and direct injection has led to engines that are not only more powerful but also significantly more fuel-efficient. Furthermore, advancements in materials science have enabled the creation of lighter yet stronger engine components, reducing overall vehicle weight and improving performance.

In the realm of electric vehicles (EVs), the concept of an engine chamber has also evolved. While traditional engines are being phased out, understanding the dynamics of electric powertrains is crucial. The “engine chamber” in EVs is often referred to as the powertrain, consisting of the electric motor, battery, and control systems. These components work together to deliver instantaneous torque and efficient energy use, changing the way we think about motion and energy consumption.

Environmental Considerations

With increasing focus on environmental sustainability, the engine chamber has come under scrutiny as the automotive industry transitions towards greener alternatives. Emissions regulations have prompted engineers to design cleaner engines that minimize harmful output. Technologies like catalytic converters, particulate filters, and the use of renewable fuels are becoming commonplace, addressing global concerns regarding air quality and climate change.

Moreover, the shift to alternative energy sources, such as hybrids and fully electric vehicles, highlights the need for a reimagined engine chamber. In this context, the chamber becomes a hub for integrating new technologies that support sustainable mobility solutions.

Conclusion

The engine chamber stands as a symbol of mechanical innovation and human engineering capability. Whether in traditional combustion engines or modern electric powertrains, this essential component continues to evolve, adapt, and inspire. As we look towards the future of transportation, the engine chamber will undoubtedly play a pivotal role in shaping how we harness energy and propel ourselves into the world, all while keeping in mind our responsibility to protect the planet. Thus, understanding the intricacies of the engine chamber is not only vital for engineers and manufacturers but also for anyone invested in the future of mobility.

-

Efficient Automobile Water Pump: Reliable Cooling for Engine ManifoldsNewsSep.01,2025

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025