Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Enhancing Engine Performance with Turbocharged Exhaust Manifold Design and Functionality Insights

The Importance of Turbo Exhaust Manifolds in Performance Engineering

In the realm of automotive engineering, the turbo exhaust manifold plays a crucial role in optimizing engine performance and efficiency. As vehicles increasingly shift towards forced induction systems to enhance power output while maintaining fuel efficiency, the design and functionality of turbo exhaust manifolds have garnered significant attention.

Understanding the Turbo Exhaust Manifold

At its core, the turbo exhaust manifold serves as the conduit for exhaust gases produced by the engine cylinders to flow into the turbocharger. Its primary function is to collect these gases and direct them to the turbine of the turbocharger, which then uses the energy from the exhaust flow to compress incoming air, allowing for greater combustion efficiency and power output. The efficiency and design of this manifold directly affect the performance of the turbo system and, consequently, the overall performance of the engine.

Material Considerations

One of the essential factors in the design of a turbo exhaust manifold is the choice of materials

. Given the high temperatures generated by exhaust gases, manufacturers typically use durable, heat-resistant materials such as cast iron, stainless steel, or specialized alloys. Each material has its advantages while cast iron offers excellent thermal stability and resistance to warping, stainless steel is known for its lightweight properties and resistance to rust and corrosion. Advanced composite materials are also emerging, providing innovative options for further weight reduction without compromising strength.Design and Performance Optimization

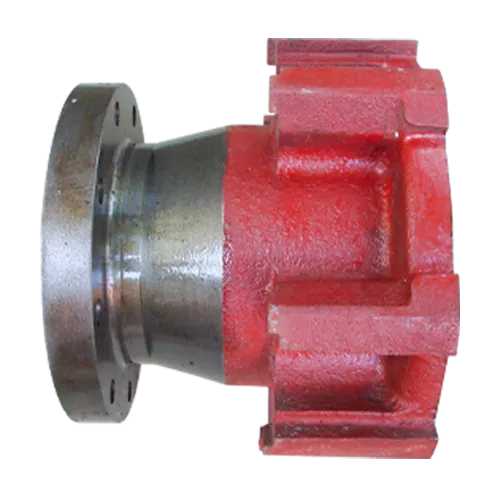

turbo exhaust manifold

The design of the turbo exhaust manifold is pivotal in minimizing exhaust back pressure and maximizing flow efficiency. A well-designed manifold will feature smooth transitions and optimal geometry to facilitate the rapid movement of exhaust gases. The layout often includes equal-length runners, which allows all cylinders to deliver exhaust gases to the turbocharger at similar rates, further enhancing responsiveness and performance.

Additionally, modern engineering techniques, such as computational fluid dynamics (CFD) simulations, are employed to analyze and optimize manifold designs before they are fabricated. This technological advancement not only improves performance but also allows for innovative designs that can meet specific performance goals while fitting within tight spatial constraints in the engine bay.

The Impact on Turbo Lag

One of the challenges associated with turbocharging is turbo lag, the delay between the driver pressing the accelerator and the turbo providing increased power. A poorly designed exhaust manifold can exacerbate this issue, as inefficiencies in gas flow can lead to delayed turbine spool-up. Engineers strive to create manifold designs that reduce lag by optimizing the exhaust flow path and ensuring quick, responsive acceleration.

Conclusion

The turbo exhaust manifold is a critical component in the pursuit of high performance in modern engine design. As the automotive industry continues to evolve, with an increasing focus on efficiency and power, the importance of innovative and effective exhaust manifold designs cannot be overstated. Effective collaboration between material scientists and engineers will likely lead to further advancements in this field, paving the way for even more powerful, efficient, and responsive engines. The turbo exhaust manifold exemplifies the intricate balance between form, function, and performance, highlighting why it remains a focal point in automotive engineering discussions.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025