Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Exploring the Final Limits of Compression Capabilities in Modern Technology and Its Impact on Efficiency

Understanding Compression Cap End A Crucial Component in Engineering

In the realm of engineering, particularly in fields related to mechanics and structural design, the concept of compression cap end plays a vital role in ensuring the stability and integrity of various structures. Compression cap ends are used primarily in cylindrical structures, such as pipes and tubes, to safely distribute loads and manage stresses that arise during operation. Understanding the technical specifications and operational importance of compression cap ends is essential for engineers, designers, and technicians alike.

Defining Compression Cap Ends

A compression cap end refers to a type of closure or termination found at the end of a cylindrical component, designed to withstand compressive forces. These components help to seal the ends of pipes or tubes while also reinforcing the structure against axial loads. They are often fabricated from robust materials such as steel, aluminum, or high-strength polymers, tailored to suit specific applications ranging from industrial machinery to construction projects.

Importance in Structural Integrity

The primary aim of using compression cap ends is to ensure that the entire structure can endure loads without significant deformation or failure. When a cylindrical body experiences compressive forces, the ends must transfer these forces effectively across the material. If the ends are not adequately designed or installed, there is a risk of buckling, deformation, or even catastrophic failure of the entire system.

Compression cap ends serve to manage these risks by providing a stable interface that maintains the integrity of the structure

. They help in distributing stresses more evenly and prevent localized failures that could compromise the entire system. In critical applications, such as pressure vessels or load-bearing columns, the reliability of compression cap ends is paramount.Design Considerations

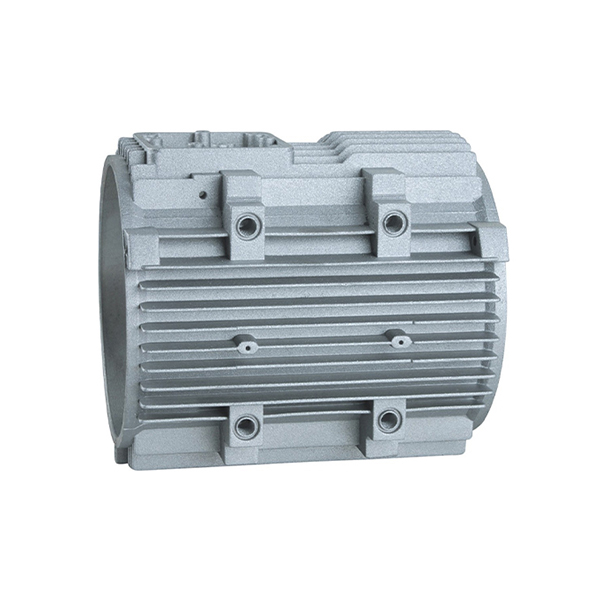

compression cap end

When designing compression cap ends, engineers must consider several factors, including material selection, thickness, and the method of attachment to the main structure. The material used must possess adequate mechanical properties to withstand the anticipated loads, including tensile strength, yield strength, and fatigue resistance. The thickness of the cap end also determines its ability to resist deformation and failure, and it should be designed based on the overall dimensions and required performance of the cylindrical component.

Moreover, the type of attachment used—whether welded, bolted, or mechanically fastened—will influence the overall strength and stability of the assembly. Each method has its advantages and drawbacks, which must be carefully evaluated based on the specific application.

Applications Across Industries

Compression cap ends find applications across various industries, including construction, automotive, aerospace, and manufacturing. In the construction industry, they are commonly used in load-bearing columns and pipes, providing essential support and stability. In automotive applications, they may be found in exhaust systems and drive shafts, where they must withstand high levels of stress and heat.

In the aerospace sector, compression cap ends play critical roles in fuel tanks and structural components of aircraft, where safety and reliability are of utmost importance. The manufacturing industry also utilizes these components in machinery where pressure and load management are crucial for operation.

Conclusion

In summary, compression cap ends are integral components in many engineering applications, serving to enhance the structural integrity of cylindrical systems. By effectively managing compressive forces and distributing loads, they play a crucial role in preventing failures that could lead to significant safety hazards. As industries continue to evolve and push the boundaries of engineering, the importance of reliable and well-designed compression cap ends cannot be overstated. Engineers must continue to innovate in their designs to ensure these critical components meet the growing demands of modern applications.

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025