Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jun . 25, 2024 21:15

Back to list

Dust Collector Impeller Efficient Cleaning and Maintenance Tips

The Dust Collector Impeller A Revolutionary Innovation in Industrial Cleaning

In the realm of industrial manufacturing and processing, maintaining a clean and safe environment is paramount. One of the most significant challenges faced by industries involves the effective removal of airborne dust and particulate matter generated during production processes. This is where the dust collector impeller comes into play, representing a revolutionary innovation in industrial cleaning technology.

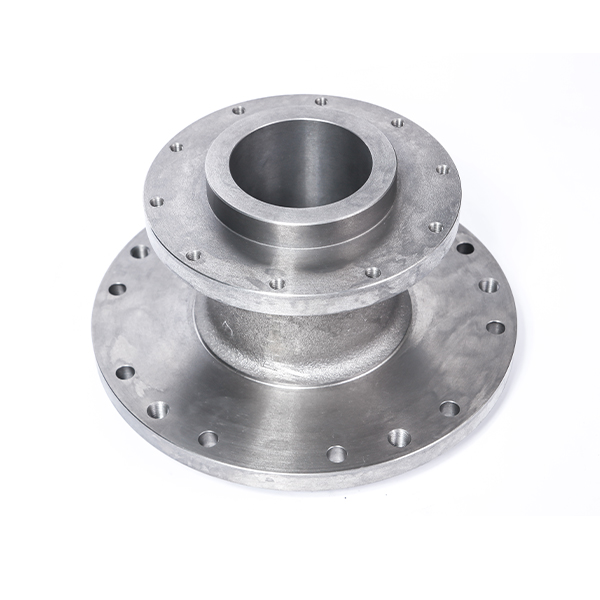

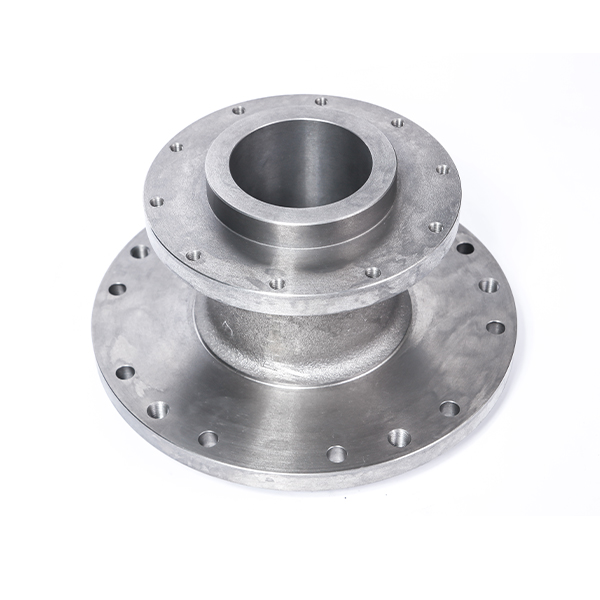

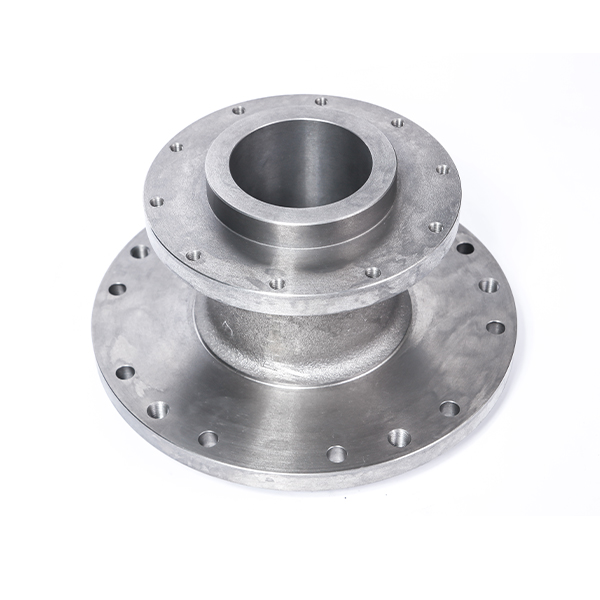

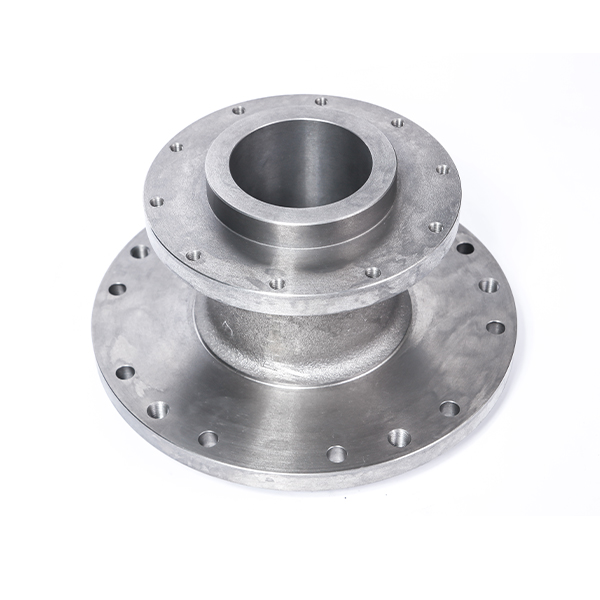

A dust collector impeller is an essential component of a dust collection system, which is designed to filter out harmful particles from the air. The impeller works on the principle of centrifugal force, spinning at high speeds to generate a powerful draft that pulls dust-laden air through the system. As the air moves, the impeller forces the dust particles out of the airflow and into a collection bin or disposal chute.

The design of the dust collector impeller is both simple and ingenious. It typically consists of a rotating drum with blades or vanes attached, powered by an electric motor. The shape and angle of these blades are carefully engineered to optimize airflow and particle separation, ensuring that even the finest dust particles are captured and removed from the airstream.

One of the key advantages of the dust collector impeller is its efficiency. Unlike traditional filtration methods that can become clogged or less effective over time, an impeller-based system maintains consistent performance due to its dynamic nature. The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements

The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements dust collector impeller.

Another benefit is the scalability of dust collector impellers. They come in various sizes and capacities, making them suitable for everything from small workshops to large industrial facilities. Whether dealing with wood chips, metal shavings, or chemical powders, the right impeller can be selected and integrated into the dust collection system to suit specific needs.

From a safety standpoint, dust collector impellers help to minimize health risks associated with prolonged exposure to airborne contaminants. Respirable particles, those small enough to enter the lungs, are particularly hazardous and can lead to respiratory issues among workers. By effectively removing these particles from the air, dust collector impellers contribute to a healthier workplace environment.

In conclusion, the dust collector impeller represents a critical advancement in industrial cleaning technology. Its ability to consistently and efficiently remove dust particles from the air not only improves the quality of the work environment but also enhances productivity and reduces maintenance costs. As industries continue to evolve and prioritize cleanliness and safety, the dust collector impeller will undoubtedly remain a cornerstone of effective dust control solutions.

dust collector impeller.

Another benefit is the scalability of dust collector impellers. They come in various sizes and capacities, making them suitable for everything from small workshops to large industrial facilities. Whether dealing with wood chips, metal shavings, or chemical powders, the right impeller can be selected and integrated into the dust collection system to suit specific needs.

From a safety standpoint, dust collector impellers help to minimize health risks associated with prolonged exposure to airborne contaminants. Respirable particles, those small enough to enter the lungs, are particularly hazardous and can lead to respiratory issues among workers. By effectively removing these particles from the air, dust collector impellers contribute to a healthier workplace environment.

In conclusion, the dust collector impeller represents a critical advancement in industrial cleaning technology. Its ability to consistently and efficiently remove dust particles from the air not only improves the quality of the work environment but also enhances productivity and reduces maintenance costs. As industries continue to evolve and prioritize cleanliness and safety, the dust collector impeller will undoubtedly remain a cornerstone of effective dust control solutions.

The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements

The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements The continuous rotation of the impeller keeps the filter media clear, preventing buildup and reducing maintenance requirements dust collector impeller.

Another benefit is the scalability of dust collector impellers. They come in various sizes and capacities, making them suitable for everything from small workshops to large industrial facilities. Whether dealing with wood chips, metal shavings, or chemical powders, the right impeller can be selected and integrated into the dust collection system to suit specific needs.

From a safety standpoint, dust collector impellers help to minimize health risks associated with prolonged exposure to airborne contaminants. Respirable particles, those small enough to enter the lungs, are particularly hazardous and can lead to respiratory issues among workers. By effectively removing these particles from the air, dust collector impellers contribute to a healthier workplace environment.

In conclusion, the dust collector impeller represents a critical advancement in industrial cleaning technology. Its ability to consistently and efficiently remove dust particles from the air not only improves the quality of the work environment but also enhances productivity and reduces maintenance costs. As industries continue to evolve and prioritize cleanliness and safety, the dust collector impeller will undoubtedly remain a cornerstone of effective dust control solutions.

dust collector impeller.

Another benefit is the scalability of dust collector impellers. They come in various sizes and capacities, making them suitable for everything from small workshops to large industrial facilities. Whether dealing with wood chips, metal shavings, or chemical powders, the right impeller can be selected and integrated into the dust collection system to suit specific needs.

From a safety standpoint, dust collector impellers help to minimize health risks associated with prolonged exposure to airborne contaminants. Respirable particles, those small enough to enter the lungs, are particularly hazardous and can lead to respiratory issues among workers. By effectively removing these particles from the air, dust collector impellers contribute to a healthier workplace environment.

In conclusion, the dust collector impeller represents a critical advancement in industrial cleaning technology. Its ability to consistently and efficiently remove dust particles from the air not only improves the quality of the work environment but also enhances productivity and reduces maintenance costs. As industries continue to evolve and prioritize cleanliness and safety, the dust collector impeller will undoubtedly remain a cornerstone of effective dust control solutions. Latest news

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

Related PRODUCTS