Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Design and Functionality of Turbo Bearing Housing in High-Performance Engine Applications

Understanding Turbo Bearing Housing An Essential Component in Turbochargers

Turbocharging has become a vital technology in the automotive industry, enhancing the performance and efficiency of internal combustion engines. At the heart of every turbocharger lies a component that plays a crucial role in its functionality the turbo bearing housing. This article delves into the significance of turbo bearing housing, its design, and its impact on turbocharger performance.

What is Turbo Bearing Housing?

Turbo bearing housing is a specialized component that houses the bearings of a turbocharger. It serves as the foundation to support the shaft, facilitating smooth rotation and minimizing friction. The housing not only secures the bearings but also provides an interface between the turbocharger and the engine, allowing for the transfer of oil and gases.

Components of Turbo Bearing Housing

The turbo bearing housing is typically made from high-strength materials, often aluminum or cast iron, to withstand the significant stress and temperatures generated during engine operation. Within the housing, the following key elements are found

1. Bearings Turbochargers usually employ either journal bearings or ball bearings. Journal bearings are the most common, providing adequate support at lower costs, while ball bearings offer better performance and faster spool-up times but tend to be more expensive.

2. Oil Supply Passage This feature channels oil from the engine to lubricate the bearings, ensuring that the turbocharger operates smoothly and efficiently. Proper lubrication is essential to prevent wear and overheating.

3. Wastegate Port Some turbo bearing housings include a wastegate port that allows excess pressure to escape, preventing damage to the turbocharger and the engine. This mechanism ensures that the turbocharger operates within its optimal range.

4. Mounting Flanges These flanges connect the turbocharger to the exhaust manifold and intake system. A secure connection is necessary to maintain the reliability and efficiency of the system.

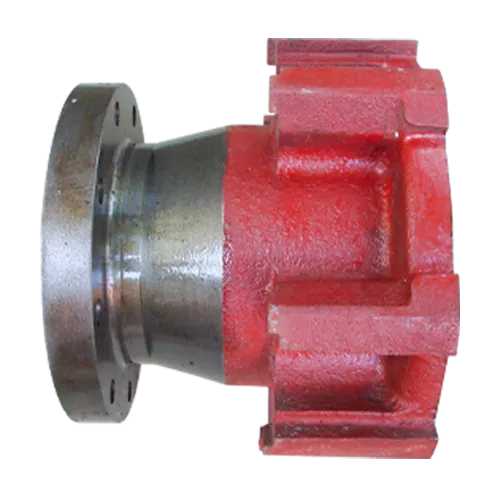

turbo bearing housing

Importance of Turbo Bearing Housing

The turbo bearing housing is critical for several reasons. First, it contributes to the overall durability and longevity of the turbocharger. A well-designed housing helps distribute the load evenly across the bearings, reducing the likelihood of failure due to wear and tear.

Second, the housing plays an integral role in heat dissipation. Turbochargers operate at extremely high temperatures, and an effective bearing housing helps manage this heat, thus preventing overheating and potential damage to critical components.

Finally, the design of the turbo bearing housing can influence turbocharger response. A lightweight and aerodynamically efficient housing can enhance turbo spool time, allowing for quicker acceleration and improved engine performance.

Innovations and Advancements

In recent years, innovations in turbo bearing housing design have led to advancements in materials and manufacturing processes. For instance, the introduction of ceramic coatings has improved heat resistance and friction reduction, allowing for enhanced performance in high-temperature environments.

Moreover, the advent of 3D printing technology has opened new avenues for custom designs, enabling manufacturers to create tailor-made housing solutions that better meet the specific requirements of different engines and applications.

Conclusion

In conclusion, the turbo bearing housing is a pivotal component in the turbocharger system that significantly impacts overall engine performance and reliability. Understanding its design and function allows automotive engineers and enthusiasts alike to appreciate the intricate workings of turbocharging technology. As the automotive industry continues to evolve, advancements in turbo bearing housing will likely play a crucial role in the development of more efficient and powerful engines, driving innovation forward in performance and sustainability.

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025