Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Creating Engaging Game Environments with Innovative Design Concepts and Cutting-Edge Technology in Development

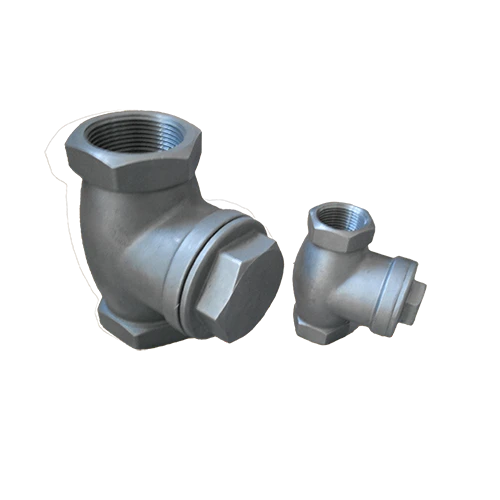

The Fascinating World of Valves Essential Components in Modern Engineering

Valves are ubiquitous in various industries and play a crucial role in controlling the flow of fluids, gases, and even solids. From the intricate plumbing systems in our homes to the complex networks in chemical plants, valves ensure safety, efficiency, and reliability. As we delve into the fascinating world of valves, we'll explore their functions, types, and significance in modern engineering.

The Function of Valves

At its core, a valve is a mechanical device designed to regulate, direct, or control the flow of fluids in a system. By opening, closing, or partially obstructing passageways, valves help maintain desired pressure levels, control the flow rate, and prevent backflow. They are integral in systems that require precise control, such as heating and cooling systems, water treatment plants, and even in the aerospace and automotive industries.

Types of Valves

Valves come in a variety of shapes and sizes, each tailored for specific applications. Here are some of the most common types

1. Gate Valve This type of valve is used primarily for on/off control. It opens and closes by lifting a gate out of the path of the fluid. Gate valves are typically used in applications where a straight-line flow of fluid without pressure drop is required.

2. Globe Valve Known for its excellent throttling capabilities, the globe valve is designed to regulate flow in a pipeline. Its spherical body improves the control over fluid flow, making it ideal for applications needing precise adjustments.

valve

3. Ball Valve Featuring a spherical disc that controls flow, the ball valve is favored for its quick operation and ability to provide a complete shut-off. These valves are extremely durable and are often used in gas and oil applications.

4. Butterfly Valve This type of valve consists of a rotating disc that regulates flow. It is lightweight and requires less space, making it suitable for large-scale applications like water distribution systems.

5. Check Valve Often referred to as a non-return valve, it allows fluid to flow in one direction only, preventing backflow. Check valves are critical for protecting systems from potential backflow damage.

Importance in Engineering

Valves are essential in numerous engineering applications. In the water distribution sector, they play a pivotal role in managing water supply and preventing contamination. In the oil and gas industry, they help control the flow of crude oil, reinforcing safety measures to handle high-pressure systems. In the pharmaceutical and food industries, valves must meet stringent regulations, ensuring hygiene and preventing contamination.

Moreover, advancements in valve technology continue to enhance their functionality. Smart valves equipped with sensors and automation technology allow for real-time monitoring and remote control, optimizing processes and improving safety.

Conclusion

In conclusion, valves are fundamental components that significantly impact the functionality and safety of various systems in modern engineering. Their diverse types cater to different applications, ensuring efficient flow management across multiple industries. As technology advances, the evolution of valves and their capabilities will undoubtedly continue, leading to enhanced performance, safety, and efficiency in fluid management systems. Understanding the importance of valves not only enhances appreciation for these unsung heroes of engineering but also underscores their pivotal role in shaping our infrastructure and industrial practices.

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025