Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jun . 16, 2024 02:45

Back to list

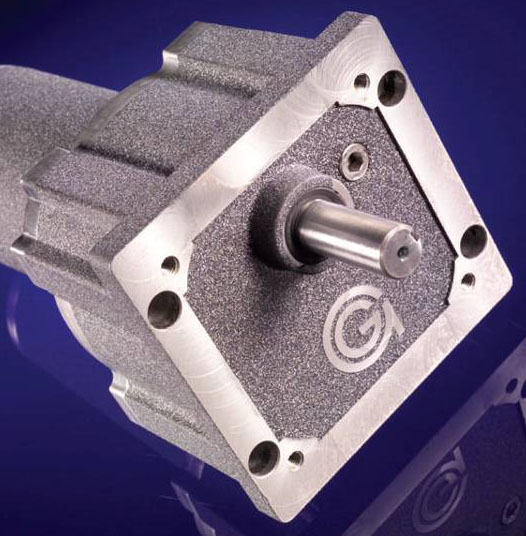

Bearing housing manufactured from casting

The Significance of Bearing Housing Castings in Modern Engineering

In the intricate world of mechanical engineering, one component that often goes unnoticed but plays a pivotal role is the bearing housing casting. This seemingly simple element is a testament to the power of precision engineering and its impact on overall system performance. A bearing housing, essentially a casing or structure that holds and supports a bearing, is a critical part of various machines, from industrial machinery to automotive systems.

A bearing housing casting is primarily a process where molten metal is poured into a mold to create a solid structure, designed specifically to accommodate and protect bearings. The term 'casting' refers to the manufacturing method, which involves shaping the metal while it's in a molten state, allowing for intricate designs and shapes that can't be achieved through other fabrication techniques. The material used, usually steel, iron, or aluminum, is chosen based on the application's requirements, such as load-bearing capacity, corrosion resistance, or thermal conductivity.

The importance of bearing housing castings lies in their ability to ensure the accurate alignment and secure mounting of bearings. They shield the bearings from external contaminants, prevent lubricant leakage, and maintain proper bearing temperature, thereby prolonging the life and efficiency of the bearing. Moreover, they distribute loads evenly, minimizing stress points that could lead to premature failure.

The casting process also offers flexibility in design. Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications

Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications bearing housing casting. Furthermore, the casting method allows for the integration of features like mounting holes, seals, and cooling channels directly into the housing, reducing assembly time and complexity.

In modern engineering, bearing housing castings have evolved with technological advancements. Precision casting techniques ensure tighter tolerances, while lightweight materials are being explored to reduce overall machine weight without compromising strength. Additive manufacturing, or 3D printing, is also revolutionizing the production of bearing housings, offering the potential for rapid prototyping and complex geometries.

In conclusion, bearing housing castings are more than just a housing; they are the backbone of numerous mechanical systems. Their role in maintaining the integrity, performance, and longevity of bearings cannot be overstated. As technology continues to advance, we can expect even more innovative solutions in bearing housing casting design and manufacturing, further enhancing the functionality and durability of machines across industries. Despite their unassuming appearance, these components stand as a testament to the crucial role played by seemingly small elements in the grand scheme of engineering.

bearing housing casting. Furthermore, the casting method allows for the integration of features like mounting holes, seals, and cooling channels directly into the housing, reducing assembly time and complexity.

In modern engineering, bearing housing castings have evolved with technological advancements. Precision casting techniques ensure tighter tolerances, while lightweight materials are being explored to reduce overall machine weight without compromising strength. Additive manufacturing, or 3D printing, is also revolutionizing the production of bearing housings, offering the potential for rapid prototyping and complex geometries.

In conclusion, bearing housing castings are more than just a housing; they are the backbone of numerous mechanical systems. Their role in maintaining the integrity, performance, and longevity of bearings cannot be overstated. As technology continues to advance, we can expect even more innovative solutions in bearing housing casting design and manufacturing, further enhancing the functionality and durability of machines across industries. Despite their unassuming appearance, these components stand as a testament to the crucial role played by seemingly small elements in the grand scheme of engineering.

Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications

Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications Customized bearing housings can be manufactured to fit specific bearing sizes and configurations, making them adaptable to diverse industrial applications bearing housing casting. Furthermore, the casting method allows for the integration of features like mounting holes, seals, and cooling channels directly into the housing, reducing assembly time and complexity.

In modern engineering, bearing housing castings have evolved with technological advancements. Precision casting techniques ensure tighter tolerances, while lightweight materials are being explored to reduce overall machine weight without compromising strength. Additive manufacturing, or 3D printing, is also revolutionizing the production of bearing housings, offering the potential for rapid prototyping and complex geometries.

In conclusion, bearing housing castings are more than just a housing; they are the backbone of numerous mechanical systems. Their role in maintaining the integrity, performance, and longevity of bearings cannot be overstated. As technology continues to advance, we can expect even more innovative solutions in bearing housing casting design and manufacturing, further enhancing the functionality and durability of machines across industries. Despite their unassuming appearance, these components stand as a testament to the crucial role played by seemingly small elements in the grand scheme of engineering.

bearing housing casting. Furthermore, the casting method allows for the integration of features like mounting holes, seals, and cooling channels directly into the housing, reducing assembly time and complexity.

In modern engineering, bearing housing castings have evolved with technological advancements. Precision casting techniques ensure tighter tolerances, while lightweight materials are being explored to reduce overall machine weight without compromising strength. Additive manufacturing, or 3D printing, is also revolutionizing the production of bearing housings, offering the potential for rapid prototyping and complex geometries.

In conclusion, bearing housing castings are more than just a housing; they are the backbone of numerous mechanical systems. Their role in maintaining the integrity, performance, and longevity of bearings cannot be overstated. As technology continues to advance, we can expect even more innovative solutions in bearing housing casting design and manufacturing, further enhancing the functionality and durability of machines across industries. Despite their unassuming appearance, these components stand as a testament to the crucial role played by seemingly small elements in the grand scheme of engineering. Latest news

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

Related PRODUCTS