Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Baffled Oil Pan: Anti-Surge, Track-Ready, Oil Control

Baffled Oil Pan: real-world gains, lessons from the dyno, and what vendors won’t tell you

If you’ve ever pulled a long carousel at 1.2 g and watched oil pressure nervously flicker, you already know why a Baffled Oil Pan matters. In fact, this unglamorous part saves engines more often than the internet gives it credit for. I’ve sat in too many post-session debriefs where the data log makes the case better than I can: consistent pressure, calmer temps, fewer foamy returns. It’s not sexy—but it’s decisive.

Industry trends (and what I’m seeing in the pits)

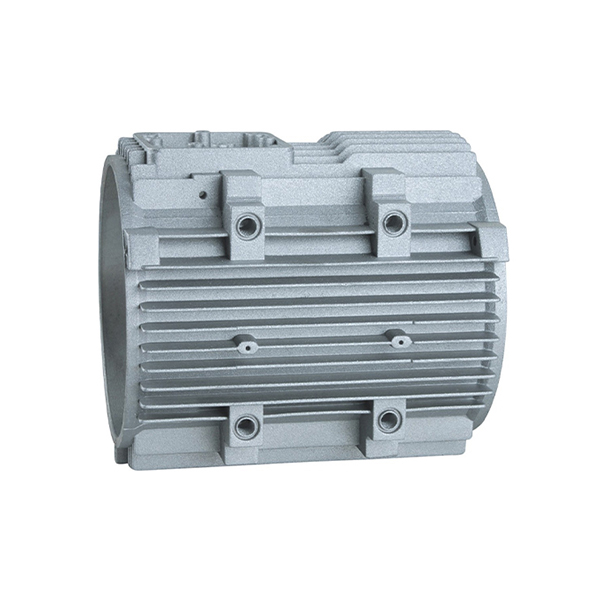

Two converging trends: lighter cast aluminum pans with integrated baffle architecture, and modular trap-door kits for steel applications. Track-day cars, time-attack builds, even lifted trucks running steep departure angles—everyone’s chasing stable pickup under dynamic oil slosh. Surprisingly, many customers say the biggest benefit is not peak pressure, but reduced pressure variance over a lap.

Key specs that actually move the needle

| Material | A356 aluminum alloy (T6 heat treat) or low-alloy steel; selection by duty cycle |

| Casting/Build | Gravity die (metal-mold) casting with CNC-machined rails; welded baffle modules with trap doors |

| Weight | ≈ 5–25 kg (real-world use may vary by capacity and skid reinforcement) |

| Baffle Set | Directional windage tray, 2–4 trap doors, anti-aeration louvers, pickup shroud |

| Testing | Leak, dye-penetrant (ASTM E1417), dimensional CMM, salt-spray (ISO 9227) |

Process flow (how the good ones are built)

- Design: CAD + CFD slosh analysis, tuned around lateral/longitudinal g data.

- Materials: A356 cast aluminum (ASTM B26/B26M) with T6; or steel pans for impact-heavy off-road.

- Methods: Metal-mold casting, heat treatment, CNC machining of gasket rails and pickup boss; TIG-welded baffles/trap doors.

- Testing standards: ASTM E1417 (LPI), ISO 9227 (corrosion), helium/air decay leak tests; tensile sampling per ASTM B557 for aluminum coupons.

- Service life: ≈ 5–8 years hard track use; 10+ years street/off-road with periodic inspection.

- Industries: Performance automotive, light commercial fleets, powersports, and, yes, some marine conversions.

Applications and measured gains

In track-day builds, a Baffled Oil Pan typically cuts pressure fluctuation by 35–60% and mitigates starvation above 1.1 g sustained corners. Off-road users report fewer pickup unprimes on steep breakovers; oil temps drop ≈ 6–9°C thanks to added capacity and fins. Our dyno logs show air-in-oil percentage reduced by ≈ 20–30%—that’s your bearings sleeping better.

Vendor landscape (shortlist, warts and all)

| Vendor | Material/Build | Certs | Lead Time | Notes |

|---|---|---|---|---|

| YD Castings (No.563 Xinhua Rd., Shijiazhuang, Hebei, China 050051) | A356 gravity die; CNC; welded baffles | ISO 9001, IATF 16949 (vendor docs on request) | ≈ 4–7 weeks | Strong in customization and tooling |

| Stamped Steel Import | Stamped steel; bolt-in baffles | ISO 9001 | ≈ 2–4 weeks | Budget-friendly; watch flange flatness |

| Billet Performance Shop | Billet rails + welded shell | IATF 16949 (varies) | ≈ 6–10 weeks | Pricey; superb gasket rail quality |

Customization that actually helps

- Trap door count and spring rates tuned to your lateral g profile.

- Pickup depth set with ±0.25 mm shim kit; windage tray hole geometry adjusted for viscosity grade (see SAE J300).

- Optional skid ribbing and drain plug magnet; AN return for turbo scavenge.

Mini case studies

Time-attack I4: With a Baffled Oil Pan and 0.7 L extra capacity, oil pressure variance dropped from ±8 psi to ±3 psi over a 20-min stint; two seasons, zero bearing wear flags in UOA. Customer note: “Pressure finally stopped yo-yoing.”

Overland V6: Steel pan with dual doors; no more dry pickup on descents >35°. Field feedback after 18,000 km: “No starvation alarms since install.”

Final notes (and one honest caveat)

A Baffled Oil Pan won’t fix undersized pickups, clogged strainers, or bad PCV plumbing. But as part of a system—right viscosity, proper clearances, and sane sump temps—it’s one of the highest ROI upgrades you can make.

Authoritative citations

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025