Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

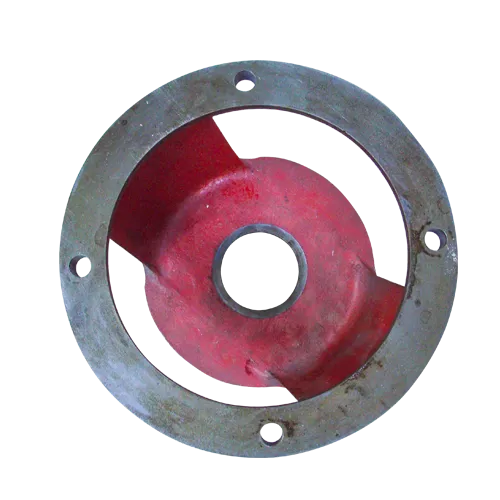

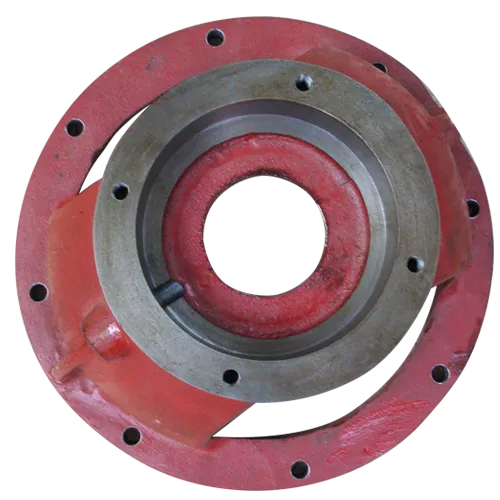

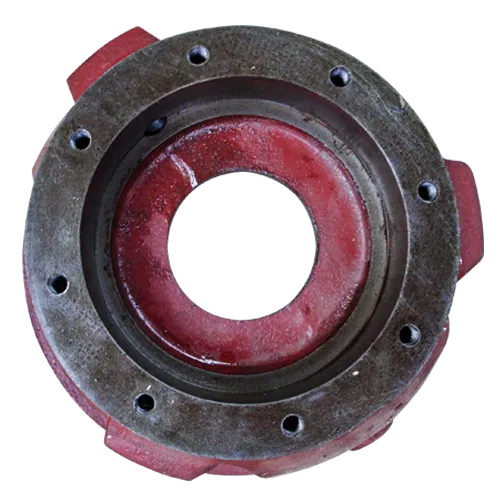

Impeller for Pumps: High Efficiency, Durable, Precision Fit

A field guide to the Impeller market in 2025: specs, trends, and real-world lessons

If you spend any time around pumps, fans, or compressors, you know the humble Impeller makes or breaks system efficiency. Lately, I’ve seen a quiet shift: more buyers are pushing for measurable performance data (not just glossy brochures), and surprisingly, more projects are coming back to cast iron where it makes sense. Not always glamorous—but reliable, serviceable, and cost-efficient.

Industry trends I’m seeing

- Efficiency pressure: tighter specs around ISO 21940 balance grades and tighter bore tolerances to reduce vibration.

- Materials fit-for-purpose: GG25 (EN-GJL-250) for water/HVAC vs. stainless or duplex for corrosives. Buyers are mixing tiers across their fleet.

- Process upgrades: more shops using 3D-printed sand cores and CFD-informed vane geometry—even for “commodity” Impeller projects.

Representative product specs (cast-iron Impeller)

Below is a typical configuration I’ve audited recently—actually similar to what many customers request for municipal water and HVAC booster sets.

| Material | GG25 (EN-GJL-250) gray iron ≈ ASTM A48 Class 40 |

| Process | Green sand casting; optional stress-relief |

| Weight | ≈ 25 kg (real-world use may vary) |

| Dimensional tolerance | ISO 8062-3 CT8 (critical bores to H7 by machining) |

| Balance | ISO 21940-11 Grade G6.3 (G2.5 on request) |

| Surface finish | Ra ≈ 6.3–12.5 µm after machining |

| Coatings | Epoxy or powder coat for water service; primer only for dry gas |

| Service life | ≈ 20,000–40,000 hours with proper alignment and filtration |

Process flow, testing, and certifications

Materials: GG25 charge with spectrometer-verified chemistry; low-S, low-P control. Methods: sand molding, controlled melt, pour, shakeout, riser removal. Machining: bore, keyway, OD, balance correction. Testing: chemical analysis; Brinell hardness (HB 190–230 typical); dimensional to ISO 8062-3; dynamic balancing to ISO 21940; surface inspection via MT/PT; X-ray for high-risk geometry when needed. Documentation: EN 10204 3.1 material certs; ISO 9001 QMS; ISO 14001 possible at larger foundries.

Application scenarios and advantages

- Pumps: clean water, HVAC booster, light slurry (with coating). The Impeller damping properties of gray iron help reduce noise.

- Fans/blowers: stable performance at moderate speeds; balance grade matters.

- General industry: mining dewatering, agriculture irrigation, OEM spares.

Vendor snapshot and comparison

From No.563 Xinhua Road, Shijiazhuang City, Hebei, China (050051), YD Castings runs sand-cast Impeller programs and related iron components. I’ve toured similar facilities—what matters is process control, not marble lobbies.

| Vendor | Core Strength | Balance Capability | Lead Time | Notes |

| YD Castings | GG25 sand-cast Impeller; cost-effective tooling | G6.3 standard; G2.5 optional | ≈ 4–6 weeks after tooling | EN 10204 3.1, ISO 9001 |

| Competitor A | Investment-cast stainless | G2.5 common | 6–10 weeks | Higher material cost; corrosion strong |

| Boutique Shop B | Small-batch prototypes | G2.5 on request | 2–4 weeks | Great for R&D; higher unit price |

Customization and real-world cases

Customization: bore/keyway to H7/JS9; coatings (NSF-style epoxy for potable water—verify certification per project); materials upgrade to ductile iron (EN-GJS-400-15) or stainless for chloride exposure; CFD-guided vane tweaks.

Case 1 (Mining dewatering): swapped a worn bronze unit for GG25 Impeller with epoxy coat; balance upgraded to G2.5. Vibration dropped ≈ 18%, MTTF improved by a season. Case 2 (HVAC booster): standardized 25 kg sand-cast Impeller across 8 SKUs; stocking cost fell ~12% thanks to shared tooling.

Quick buyer checklist

- Ask for ISO 8062-3 tolerance map and ISO 21940 balance report.

- Confirm chemistry and hardness range; request EN 10204 3.1 certs.

- For corrosives, select coating or upgrade material—don’t skimp.

- Verify service life expectations (hours) under your duty cycle.

Citations:

- ISO 8062-3: Geometrical tolerances for castings – Dimensional tolerances.

- ISO 21940 (formerly ISO 1940): Mechanical vibration – Balance quality requirements.

- EN 1561 / ASTM A48: Grey cast iron specifications and grades.

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025