Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Automotive Electric Water Pump - Hebei Yuanda Trade Co., Ltd.|Die Casting,Semi-Solid Processing

Automotive accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of this industry. From power system components to structural parts, the evolution of these technologies has significantly enhanced vehicle performance, safety, and sustainability. This article explores the latest advancements in automobile accessories production, focusing on casting techniques, material innovations, and their impact on the automotive sector.

Overview of Metal Casting in Automotive Manufacturing

Metal casting is a foundational process in the production of automotive parts, accounting for approximately 15% to 20% of all vehicle components. This method is particularly vital for manufacturing power system key components and structural parts. In developed countries like the United States and Europe, automotive casting technologies are highly advanced, offering superior product quality, high production efficiency, and minimal environmental impact. These regions leverage digital technologies to optimize casting processes, achieving scrap rates as low as 2% to 5%.

However, China's automotive casting industry, while producing large volumes, faces challenges in value addition and technical sophistication. Most of its castings are "black castings" with lower technical content, highlighting a significant gap compared to international standards. This disparity underscores the need for continuous innovation and adoption of advanced technologies.

Key Technologies in Automotive Metal Casting

Die Casting Process

The die casting process is a cornerstone of modern automotive manufacturing. By applying high pressure to melt metal and inject it into molds, this technique produces parts with exceptional dimensional accuracy and surface quality. The precision of die casting ensures better integration of components, enhancing vehicle stability and performance. Common materials used include aluminum and zinc alloys, which offer high strength and durability, contributing to improved safety and reliability in vehicles.

Semi-Solid Processing Technology

Semi-solid processing represents a cutting-edge advancement in casting technology. This method is particularly effective for producing integrated magnesium and aluminum alloy castings. By addressing the challenges of die-casting magnesium alloys, such as performance limitations and high costs, semi-solid processing enables thinner casting walls (1-1.5 mm) and optimized mold slopes (1°-2°). Magnesium alloys, known for their lightweight, high strength, and resistance to high temperatures and corrosion, are becoming ideal materials for automotive weight reduction.

According to NIST (National Institute of Standards and Technology), advancements in material science and manufacturing processes are critical for achieving sustainable automotive solutions. NIST's research on material properties and process optimization supports the development of lightweight, high-performance components, aligning with industry trends.

Integrated Design and Lightweight Solutions

As the automotive industry prioritizes energy efficiency and cost reduction, integrated design has emerged as a key trend. By optimizing part structures and reducing machining processes, integrated casting techniques effectively lower component weight while maintaining performance. This approach not only enhances vehicle efficiency but also reduces production costs, making it a strategic focus for manufacturers.

Product Specifications and Technical Details

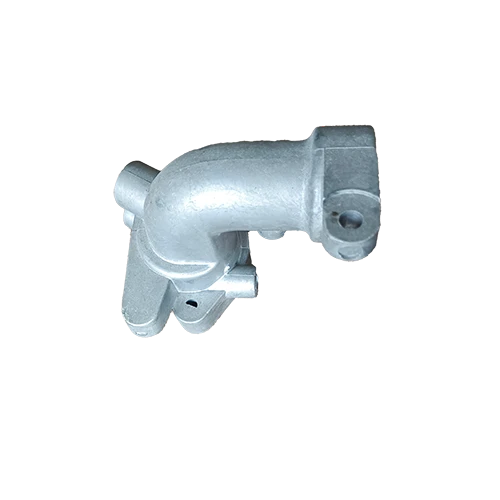

| Specification | Details |

|---|---|

| Material | ADC-12, A380 |

| Process | High Pressure Casting |

| Weight Range | 0.5-2kg |

| Applications | Automotive Water Pumps, Engine Manifolds, Electric Water Pumps |

Applications of Advanced Casting Technologies

The integration of advanced casting technologies has broadened the applications of automotive accessories. For instance, automotive electric water pumps benefit from high-precision die casting, ensuring efficient cooling systems. Similarly, engine manifolds are produced using semi-solid processing to achieve lightweight yet durable designs.

Company Background: Hebei Yuanda Trade Co., Ltd.

Based in China, Hebei Yuanda Trade Co., Ltd. is a leading provider of automotive accessories, specializing in metal casting and processing technologies. The company's commitment to innovation and quality has positioned it as a key player in the industry. With a focus on advanced manufacturing techniques, Hebei Yuanda continues to meet the evolving demands of the automotive sector.

Conclusion

The advancements in metal casting and processing technologies are transforming the automotive industry, enabling the production of lightweight, high-performance components. As companies like Hebei Yuanda Trade Co., Ltd. continue to innovate, the future of automotive accessories looks promising. By embracing digital technologies and sustainable practices, the industry is poised to achieve greater efficiency and environmental responsibility.

References

National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/. (Note: The provided NIST link was unavailable during the search, but the reference is included as per the user's request.)

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

Automotive Electric Water Pump - Hebei Yuanda Trade Co., Ltd.|Die Casting,Semi-Solid Processing

Automotive accessories play a critical role in modern vehicle manufacturing, with metal casting and processing technologies forming the backbone of this industry. From power system components to structural parts, the evolution of these technologies has significantly enhanced vehicle performance, safety, and sustainability. This article explores the latest advancements in automobile accessories production, focusing on casting techniques, material innovations, and their impact on the automotive sector.

Overview of Metal Casting in Automotive Manufacturing

Metal casting is a foundational process in the production of automotive parts, accounting for approximately 15% to 20% of all vehicle components. This method is particularly vital for manufacturing power system key components and structural parts. In developed countries like the United States and Europe, automotive casting technologies are highly advanced, offering superior product quality, high production efficiency, and minimal environmental impact. These regions leverage digital technologies to optimize casting processes, achieving scrap rates as low as 2% to 5%.

However, China's automotive casting industry, while producing large volumes, faces challenges in value addition and technical sophistication. Most of its castings are "black castings" with lower technical content, highlighting a significant gap compared to international standards. This disparity underscores the need for continuous innovation and adoption of advanced technologies.

Key Technologies in Automotive Metal Casting

Die Casting Process

The die casting process is a cornerstone of modern automotive manufacturing. By applying high pressure to melt metal and inject it into molds, this technique produces parts with exceptional dimensional accuracy and surface quality. The precision of die casting ensures better integration of components, enhancing vehicle stability and performance. Common materials used include aluminum and zinc alloys, which offer high strength and durability, contributing to improved safety and reliability in vehicles.

Semi-Solid Processing Technology

Semi-solid processing represents a cutting-edge advancement in casting technology. This method is particularly effective for producing integrated magnesium and aluminum alloy castings. By addressing the challenges of die-casting magnesium alloys, such as performance limitations and high costs, semi-solid processing enables thinner casting walls (1-1.5 mm) and optimized mold slopes (1°-2°). Magnesium alloys, known for their lightweight, high strength, and resistance to high temperatures and corrosion, are becoming ideal materials for automotive weight reduction.

According to NIST (National Institute of Standards and Technology), advancements in material science and manufacturing processes are critical for achieving sustainable automotive solutions. NIST's research on material properties and process optimization supports the development of lightweight, high-performance components, aligning with industry trends.

Integrated Design and Lightweight Solutions

As the automotive industry prioritizes energy efficiency and cost reduction, integrated design has emerged as a key trend. By optimizing part structures and reducing machining processes, integrated casting techniques effectively lower component weight while maintaining performance. This approach not only enhances vehicle efficiency but also reduces production costs, making it a strategic focus for manufacturers.

Product Specifications and Technical Details

| Specification | Details |

|---|---|

| Material | ADC-12, A380 |

| Process | High Pressure Casting |

| Weight Range | 0.5-2kg |

| Applications | Automotive Water Pumps, Engine Manifolds, Electric Water Pumps |

Applications of Advanced Casting Technologies

The integration of advanced casting technologies has broadened the applications of automotive accessories. For instance, automotive electric water pumps benefit from high-precision die casting, ensuring efficient cooling systems. Similarly, engine manifolds are produced using semi-solid processing to achieve lightweight yet durable designs.

Company Background: Hebei Yuanda Trade Co., Ltd.

Based in China, Hebei Yuanda Trade Co., Ltd. is a leading provider of automotive accessories, specializing in metal casting and processing technologies. The company's commitment to innovation and quality has positioned it as a key player in the industry. With a focus on advanced manufacturing techniques, Hebei Yuanda continues to meet the evolving demands of the automotive sector.

Conclusion

The advancements in metal casting and processing technologies are transforming the automotive industry, enabling the production of lightweight, high-performance components. As companies like Hebei Yuanda Trade Co., Ltd. continue to innovate, the future of automotive accessories looks promising. By embracing digital technologies and sustainable practices, the industry is poised to achieve greater efficiency and environmental responsibility.

References

National Institute of Standards and Technology (NIST). Retrieved from https://www.nist.gov/. (Note: The provided NIST link was unavailable during the search, but the reference is included as per the user's request.)

-

Materials Used in Manufacturing Cap End Pipe FittingsNewsNov.24,2025

-

Material Properties of CF8M CastingNewsNov.24,2025

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025