Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

Jun . 14, 2024 03:36

Back to list

Aluminum casting foundry process

Aluminum Die Casting Foundry An Industrial Revolution in Miniature

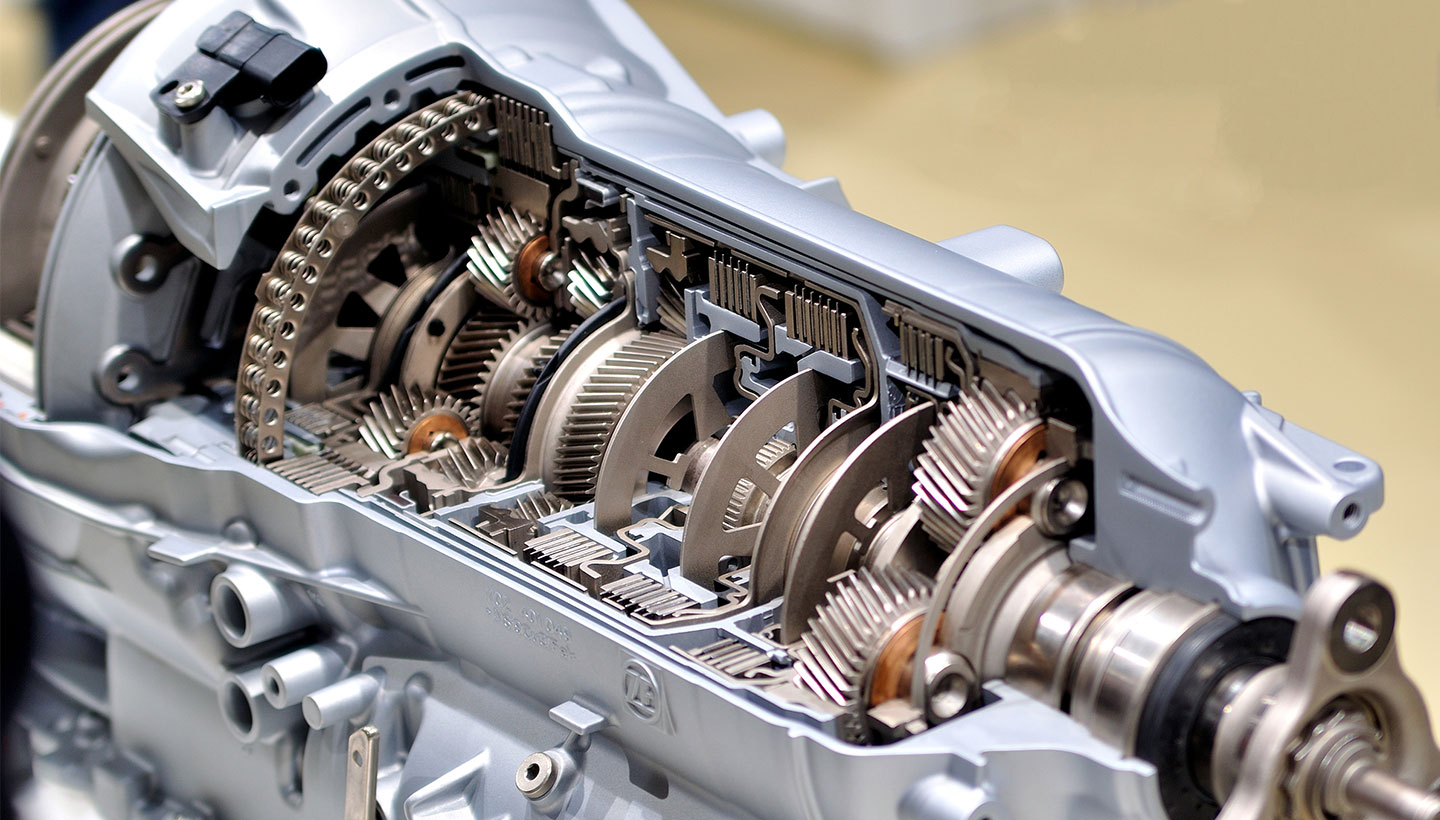

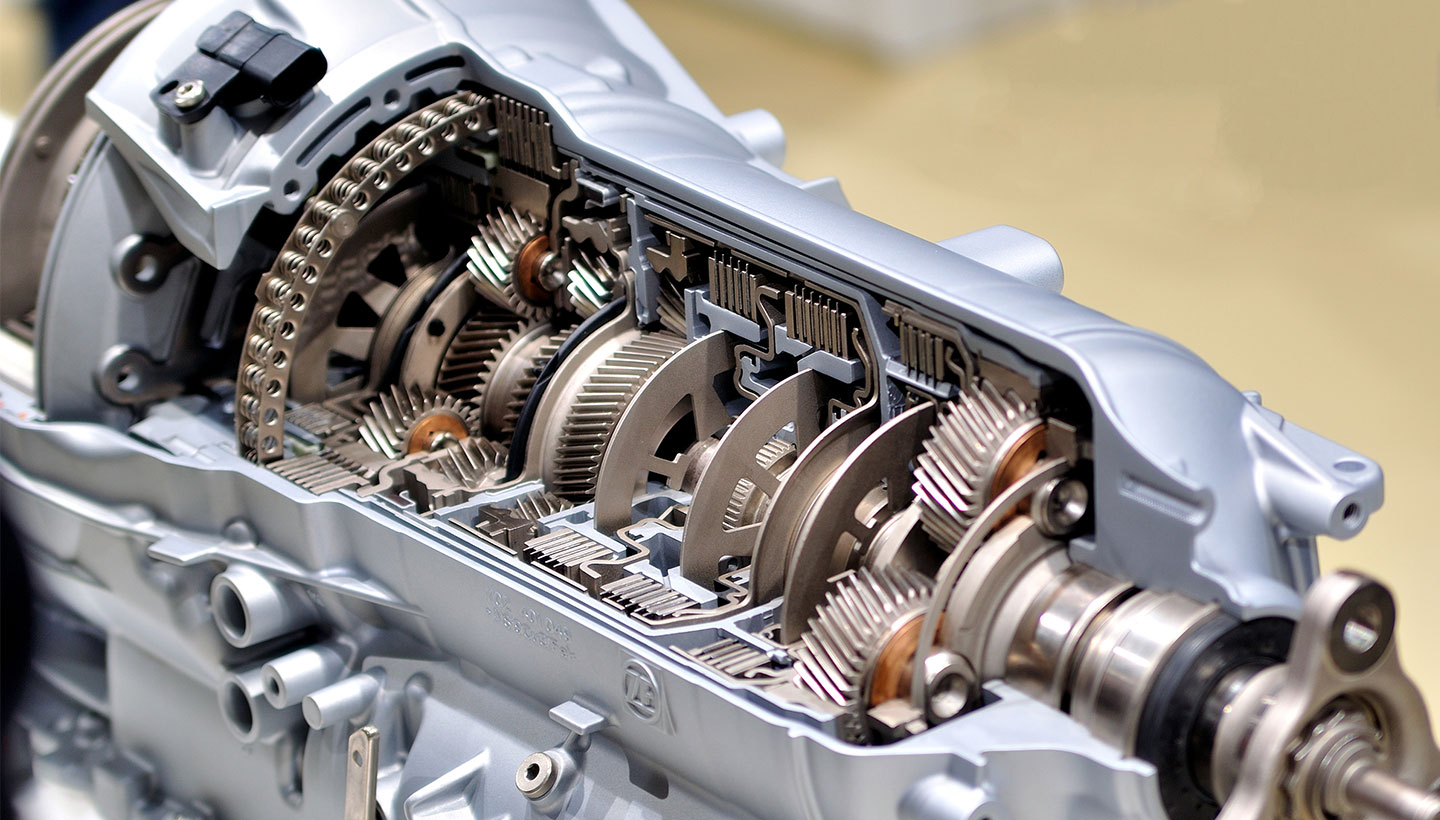

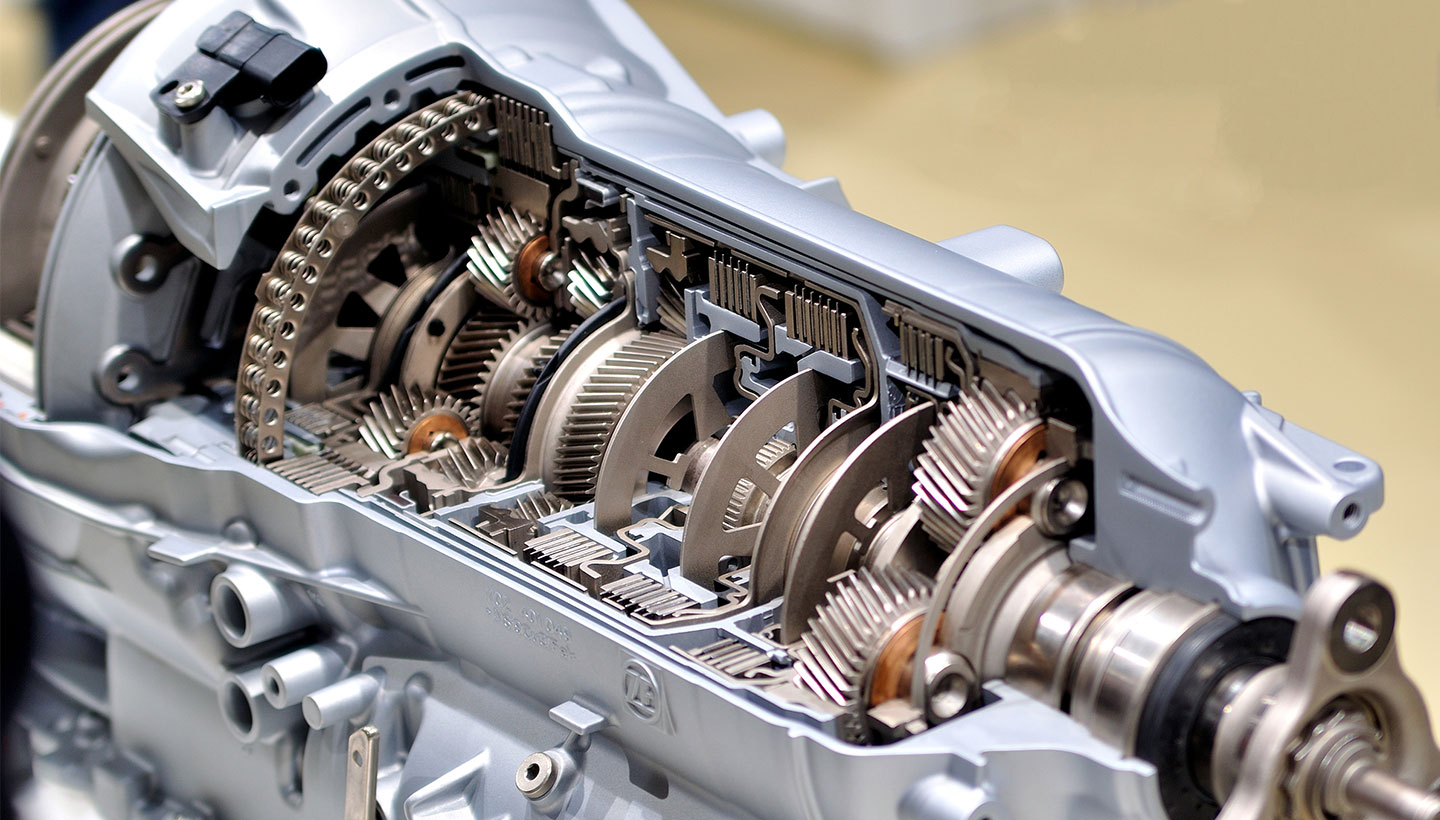

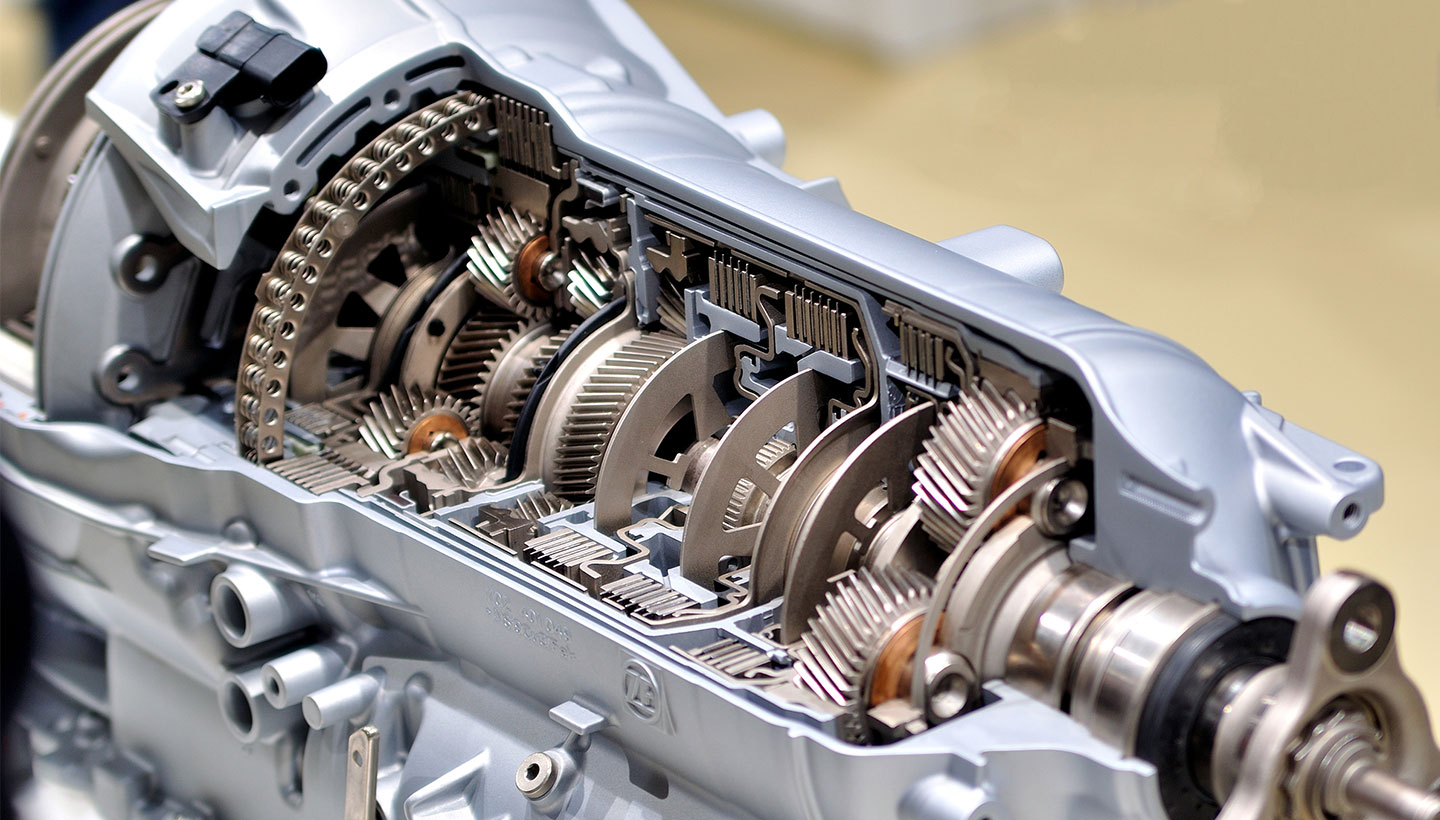

In the world of manufacturing, aluminum die casting stands as a testament to precision and efficiency. This modern marvel encapsulates an industrial revolution in miniature, where molten metal is injected into reusable molds, or dies, to produce parts of exceptional accuracy and consistency. The aluminum die casting foundry is the crucible where this transformation occurs, shaping raw materials into components that power industries ranging from automotive to aerospace.

At the heart of the process is the unyielding nature of aluminum, a material celebrated for its strength-to-weight ratio, corrosion resistance, and thermal conductivity. These properties make it an ideal candidate for die casting, a technique that demands both resilience and adaptability. As aluminum flows into the cavity of a steel die, cooled rapidly to solidify, it takes on the exact inverse shape of the cavity, replicating intricate designs with fine detail.

The foundry itself is a symphony of machinery and craftsmanship. Each die, often carved with the precision of a surgeon's scalpel, is meticulously designed to expedite the flow of aluminum, ensuring every cast part meets stringent specifications. The heat and pressure involved are carefully calculated, with temperatures soaring to over 700 degrees Celsius and injection pressures surpassing 1,000 bar. Such conditions guarantee the filling of even the most delicate features within the die.

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement aluminum die casting foundry. Technological advancements like vacuum die casting and computer-aided design have allowed for further refinements in the process. These technologies minimize defects such as porosity and improve the overall quality of the castings.

Moreover, the foundries are increasingly embracing sustainability practices. Recycling aluminum scrap and utilizing eco-friendly lubricants reduce environmental impact without sacrificing quality. The industry's commitment to green practices ensures that while aluminum die casting propels us forward technologically, it does so with a mindful nod to the health of our planet.

In conclusion, the aluminum die casting foundry is a microcosm of industrial might and finesse. It is here that molten potential is transformed into precise, reliable components. Through a blend of physical prowess and technological wizardry, these foundries continue to push the boundaries of what's possible in manufacturing, all while churning out the building blocks of the future.

aluminum die casting foundry. Technological advancements like vacuum die casting and computer-aided design have allowed for further refinements in the process. These technologies minimize defects such as porosity and improve the overall quality of the castings.

Moreover, the foundries are increasingly embracing sustainability practices. Recycling aluminum scrap and utilizing eco-friendly lubricants reduce environmental impact without sacrificing quality. The industry's commitment to green practices ensures that while aluminum die casting propels us forward technologically, it does so with a mindful nod to the health of our planet.

In conclusion, the aluminum die casting foundry is a microcosm of industrial might and finesse. It is here that molten potential is transformed into precise, reliable components. Through a blend of physical prowess and technological wizardry, these foundries continue to push the boundaries of what's possible in manufacturing, all while churning out the building blocks of the future.

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement

But the aluminum die casting foundry is not just a place of brute force and high temperatures; it is also one of innovation and continual improvement aluminum die casting foundry. Technological advancements like vacuum die casting and computer-aided design have allowed for further refinements in the process. These technologies minimize defects such as porosity and improve the overall quality of the castings.

Moreover, the foundries are increasingly embracing sustainability practices. Recycling aluminum scrap and utilizing eco-friendly lubricants reduce environmental impact without sacrificing quality. The industry's commitment to green practices ensures that while aluminum die casting propels us forward technologically, it does so with a mindful nod to the health of our planet.

In conclusion, the aluminum die casting foundry is a microcosm of industrial might and finesse. It is here that molten potential is transformed into precise, reliable components. Through a blend of physical prowess and technological wizardry, these foundries continue to push the boundaries of what's possible in manufacturing, all while churning out the building blocks of the future.

aluminum die casting foundry. Technological advancements like vacuum die casting and computer-aided design have allowed for further refinements in the process. These technologies minimize defects such as porosity and improve the overall quality of the castings.

Moreover, the foundries are increasingly embracing sustainability practices. Recycling aluminum scrap and utilizing eco-friendly lubricants reduce environmental impact without sacrificing quality. The industry's commitment to green practices ensures that while aluminum die casting propels us forward technologically, it does so with a mindful nod to the health of our planet.

In conclusion, the aluminum die casting foundry is a microcosm of industrial might and finesse. It is here that molten potential is transformed into precise, reliable components. Through a blend of physical prowess and technological wizardry, these foundries continue to push the boundaries of what's possible in manufacturing, all while churning out the building blocks of the future. Latest news

-

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025

Related PRODUCTS