Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

60mm Pipe End Cap for Durable and Reliable Sealing Solutions

Understanding 60mm Pipe End Caps A Comprehensive Overview

When it comes to plumbing, piping, or various fluid management systems, the details matter. Among these details, the use of pipe end caps can be crucial for ensuring the integrity and efficiency of a piping system. Specifically, 60mm pipe end caps play a significant role in a variety of applications, from domestic plumbing to industrial setups.

What is a Pipe End Cap?

A pipe end cap is a fitting used to seal the ends of a pipe. This component serves multiple purposes it can prevent material from escaping through the end of the pipe, protect the interior from contaminants, and, in some cases, function as a means of terminating pipe runs. Caps are essential in maintaining the pressure within the system and providing a neat and finished look to the pipelines.

The Importance of 60mm Pipe End Caps

The term 60mm refers to the diameter of the pipe that the cap is designed to fit. This size is commonly used in various applications, such as water supply lines, gas piping, and chemical transport systems. A properly fitted 60mm end cap can help prevent leaks, which are not only wasteful but can lead to costly damages or dangers in certain conditions.

60mm pipe end caps are available in various materials, including PVC, stainless steel, and carbon steel. The choice of material depends largely on the application requirements, including the type of fluid being transported, temperature, and environmental factors. For instance, PVC is often used in water systems due to its corrosion resistance and lightweight properties, whereas stainless steel may be chosen for its strength and durability in more demanding environments.

Installation and Use

60mm pipe end cap

Installing a 60mm pipe end cap is generally straightforward, but it must be done correctly to ensure a secure seal. The end of the pipe must be clean and free from debris to provide optimal adhesion. Depending on the fitting type—whether threaded, slip-on, or weld-on—installation methods will vary. For threaded caps, it’s essential to apply thread sealant to prevent leaks. In contrast, slip-on caps may require a solvent cement application to bond securely.

Additionally, if the piping system involves high-pressure scenarios, it is crucial to follow the manufacturer's guidelines regarding the specifications and installation techniques to guarantee safety and reliability.

Applications in Real Life

60mm pipe end caps are prevalent in a variety of scenarios. In residential plumbing, they can be used to close off unused lines, ensuring water or gas does not leak into the property. In industrial settings, these caps can be used in pipelines carrying chemicals or other hazardous materials, where failure to seal effectively can have dangerous consequences.

Public infrastructure also relies on 60mm pipe end caps for traffic management—think of the sewer and drainage systems where these fittings seal the ends of large pipes to prevent system failures or overflow.

Conclusion

In summary, 60mm pipe end caps play a vital role in ensuring the functionality and safety of various piping systems. Their ability to provide a secure seal not only helps maintain pressure but also contributes to the overall efficiency and integrity of fluid transport systems. As with any component in plumbing or pipeline management, selecting the correct type and material of a pipe end cap is critical to the system's success. Thus, understanding their applications, proper installation methods, and material choices is essential for anyone involved in plumbing or industrial piping work. Whether in a household setting or industrial application, these small components can make a significant difference in achieving reliable and efficient operations.

-

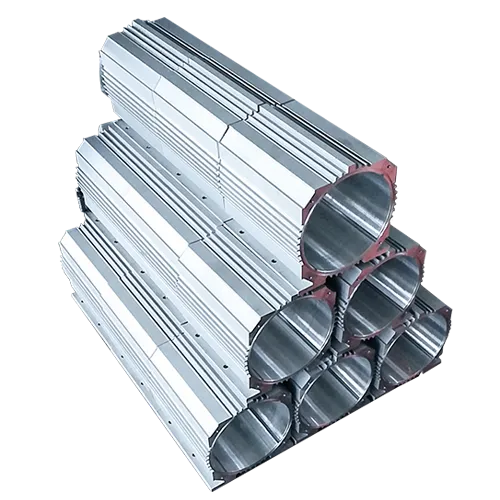

Premium Fan Housing & Motor Casing for Optimal AirflowNewsAug.31,2025

-

High-Performance Automobile Water Pump & Electric SolutionsNewsAug.30,2025

-

Expert Stainless Steel Casting | Precision & Durable Metal PartsNewsAug.29,2025

-

Precision Metal Castings: Aluminum, Stainless Steel & Die CastingNewsAug.28,2025

-

Superior Aluminum Castings in Automotive Engine PartsNewsAug.22,2025

-

Common Materials Used in Fan Housing ManufacturingNewsAug.22,2025