Mobile:+86-311-808-126-83

Email:info@ydcastings.com

1 inch 2 inch end cap options for plumbing and piping solutions

The Importance of the 1% 202 Inch End Cap in Modern Applications

In today's rapidly evolving industrial landscape, the choice of components can significantly affect the efficiency, safety, and reliability of various systems. Among these components, the 1% 202-inch end cap might seem like a small and possibly inconspicuous element, yet its role is paramount in numerous applications ranging from plumbing systems to intricate machinery.

The Importance of the 1% 202 Inch End Cap in Modern Applications

One of the primary advantages of using a 1% 202-inch end cap is its ability to prevent leaks. In any system where fluid containment is required, leaks can lead to catastrophic failures, environmental issues, and significant financial losses. The precision in measurement that the 1% standard offers, combined with high-quality materials, minimizes the risk of any discrepancies in fit that could otherwise lead to leaks. Furthermore, many end caps are designed to withstand high pressures and temperatures, making them suitable for a vast range of applications, including oil and gas, chemical processing, and even food and beverage industries.

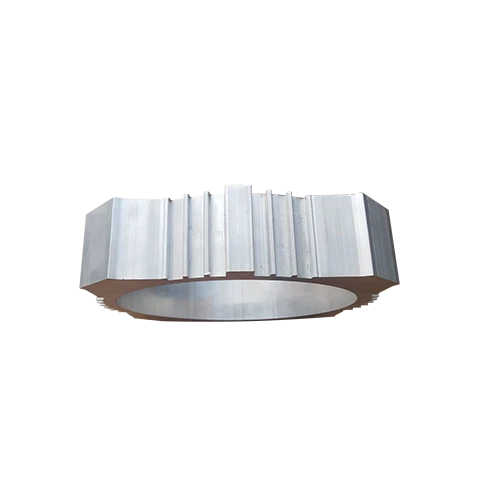

1 2 inch end cap

Another key feature of the 1% 202-inch end cap is its adaptability to various materials, including PVC, metal, and composite substances. This versatility allows for its use across different sectors, from municipal water systems to advanced aerospace engineering applications. The ability to select the right material for the end cap ensures compatibility with the transported media and the environmental conditions, thus enhancing the longevity and performance of the system.

In modern engineering practices, sustainability is a fundamental concern. The right choice of end cap can contribute significantly to the overall sustainability of a project. End caps that are produced using eco-friendly methods or that incorporate recyclable materials are becoming increasingly available, aligning with the global shift towards more sustainable industrial practices. By selecting a 1% 202-inch end cap, companies can also signal their commitment to quality and environmental responsibility.

Moreover, the design and engineering behind these components are of utmost importance. Advanced manufacturing techniques, such as CNC machining and 3D printing, have allowed for greater precision and customizability in the production of end caps. This enhances the ability to meet specific requirements and allows for innovations in design that improve performance and efficiency.

In conclusion, while the 1% 202-inch end cap may appear to be a small cog in the machinery of industry, its impact is significant. By ensuring effective sealing, compatibility with various materials, and adherence to high-quality manufacturing standards, these end caps play an essential role in the reliability and efficiency of many systems. Their versatility allows them to adapt to various applications while promoting sustainability in modern engineering practices. Thus, investing in quality end caps is not merely a matter of compliance; it is a critical step towards enhancing operational excellence and ensuring long-term success in industrial applications.

-

Why Is Choosing the Right Motor Housing Critical for Engine Performance?NewsJul.18,2025

-

Which Impeller Types Best Optimize Your Pump’s Efficiency?NewsJul.18,2025

-

Optimize Maintenance Efficiency with Durable Oil Catch SolutionsNewsJul.18,2025

-

Maximize Pump Performance with Precision-Engineered ComponentsNewsJul.18,2025

-

Elevate Industrial Flow Systems with Precision-Engineered ComponentsNewsJul.18,2025

-

Boost Durability and Functionality with Precision Power CastingsNewsJul.18,2025