Mobile:+86-311-808-126-83

Email:info@ydcastings.com

English

- Home

- NEWS

- Automotive Electric Water Pump for Cars | Optimal Engine Cooling

Automotive Electric Water Pump for Cars | Optimal Engine Cooling

The Unsung Hero: Understanding the Modern Automobile Water Pump

In the intricate ecosystem of an internal combustion engine, where temperatures soar and friction is a constant threat, one component tirelessly works to maintain thermal equilibrium: the automobile water pump. This essential device is the heart of the engine's cooling system, circulating coolant through the engine block, cylinder head, radiator, and heater core. Without a functioning automobile water pump, an engine would rapidly overheat, leading to catastrophic failure and extensive damage. Its evolution, from simple mechanical devices to sophisticated automotive electric water pump systems, reflects the automotive industry's continuous drive for efficiency, performance, and reliability.

Product Information

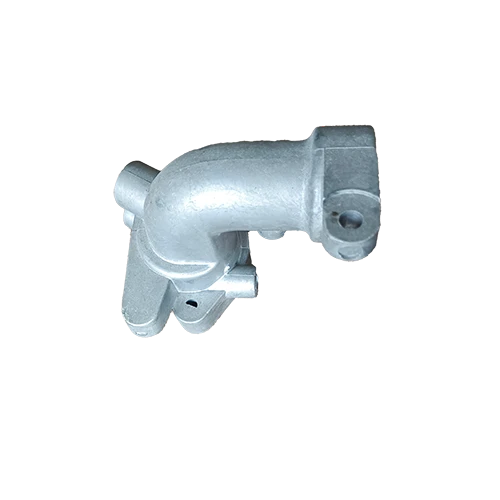

Product Name: Automobile accessories

Product URL: https://www.ydcastings.com/automobile-accessories.html

Industry Trends & The Future of Engine Cooling

The automotive industry is undergoing a profound transformation, driven primarily by the global shift towards electrification and more stringent emission regulations. These trends directly impact the design and functionality of the automobile water pump.

- Electrification and Automotive Electric Water Pump: Traditional mechanical water pumps are engine-driven, meaning their speed and efficiency are directly tied to the engine's RPM. This often results in suboptimal cooling at low RPMs or wasted energy at high RPMs. The advent of the electric water pump for car offers precise, on-demand cooling, independent of engine speed. This allows for more efficient engine warm-up, reduced parasitic losses, and improved fuel economy. For hybrid and electric vehicles, these pumps are crucial for managing battery and power electronics thermal loads.

- Thermal Management Complexity: Modern vehicles, especially those with turbochargers, direct injection, and complex emission control systems (like EGR coolers), require highly sophisticated thermal management. This often involves multiple cooling circuits and pumps, including dedicated pumps for engine oil cooling, transmission cooling, and even specific components like the engine manifolds.

- Lightweighting and Material Innovation: To meet fuel efficiency targets, there's a constant push for lighter components. This drives innovation in materials for water pump housings (e.g., advanced aluminum alloys, reinforced plastics) and impellers, balancing strength with weight reduction.

- Enhanced Durability and Lifespan: Consumers and manufacturers demand components that last the lifetime of the vehicle. This requires superior bearing designs, advanced seal materials, and robust construction to withstand extreme temperatures, vibrations, and corrosive coolants.

Industry analysts project significant growth in the electric water pump market. According to a report by MarketsandMarkets, the global electric water pump market size is projected to grow from USD 2.3 billion in 2022 to USD 4.9 billion by 2027, at a CAGR of 16.4%. This growth is primarily attributed to the increasing production of hybrid and electric vehicles and the rising demand for fuel-efficient vehicles. This makes the production of high-quality auto electric water pump systems a critical focus for manufacturers.

+16.4%

Projected CAGR for Electric Water Pump Market (2022-2027)

4.9 Billion USD

Estimated Electric Water Pump Market Size by 2027

20%

Potential Fuel Economy Improvement with Electric Pumps

50%

Reduction in Parasitic Losses with Electric Pumps

Technical Parameters & Design Principles of Automobile Water Pumps

A deep understanding of the technical parameters and design principles is crucial for developing high-performance automobile water pump solutions. These pumps are typically centrifugal pumps, meaning they use a rotating impeller to increase the pressure of the coolant and force it through the cooling system.

Key Components:

- Housing: The outer casing, typically made of cast iron or aluminum, that contains the coolant and internal components. It often includes mounting points for the engine and inlet/outlet ports.

- Impeller: The rotating component with vanes that imparts kinetic energy to the coolant, driving it through the system. Impeller design (number of vanes, shape, diameter) critically affects flow rate and pressure.

- Shaft: Connects the impeller to the power source (engine belt for mechanical pumps, electric motor for electric pumps).

- Bearings: Support the rotating shaft and impeller, ensuring smooth operation and minimizing friction. Common types include ball bearings or roller bearings, designed for high loads and temperatures.

- Mechanical Seal: A critical component that prevents coolant leakage along the rotating shaft where it exits the pump housing. These seals are designed to withstand high temperatures, pressures, and chemical exposure from coolants.

- Gasket/O-rings: Provide static seals between the pump and the engine block.

Key Technical Parameters:

When selecting or designing an automobile water pump, several critical parameters must be considered to ensure optimal engine cooling performance and efficiency:

| Parameter | Description | Typical Range (Mechanical Pump) | Typical Range (Electric Pump) | Impact on Performance |

|---|---|---|---|---|

| Flow Rate (LPM / GPM) | Volume of coolant circulated per minute. | 50-200 LPM | 20-150 LPM (variable) | Directly impacts heat rejection capacity. Higher flow rate means more heat removed. |

| Pressure Head (meters H2O / PSI) | The maximum height or resistance the pump can overcome. | 8-25 meters H2O | 5-20 meters H2O (variable) | Ensures coolant reaches all parts of the system and overcomes flow resistance. |

| Power Consumption (Watts / HP) | Energy required to operate the pump. | ~1-5 HP (parasitic) | 50-500 Watts (variable) | Affects engine efficiency (mechanical) or battery range (electric). Lower is better. |

| RPM Range | Operating rotational speed of the impeller. | 500-6000 RPM (engine dependent) | 0-8000 RPM (electronically controlled) | Dictates flow rate and pressure generation. Electric pumps offer wider, precise control. |

| Material Composition | Materials used for housing, impeller, shaft, seals. | Cast Iron, Aluminum Alloys (Housing); Stamped Steel, Cast Iron, Reinforced Plastic (Impeller) | Aluminum Alloys, Reinforced Plastics (Housing); Reinforced Plastic (Impeller); Stainless Steel (Shaft) | Determines durability, corrosion resistance, weight, heat dissipation. |

| Lifespan (Operating Hours / Miles) | Expected operational life before failure. | 100,000 - 150,000 miles (approx. 3,000-5,000 hrs) | 150,000 - 200,000 miles (approx. 5,000-7,000 hrs+) | Crucial for reliability and maintenance intervals. High-quality components extend life. |

| Noise Level (dB) | Audible output during operation. | Moderate (belt/bearing noise) | Very Low (electric motor noise) | Important for passenger comfort, especially in EVs. |

Fig 1: Exploded view illustrating the critical components of a modern automobile water pump, highlighting the impeller, housing, and sealing elements.

Manufacturing Process of the Automobile Water Pump: Precision Engineering in Action

The manufacturing of a high-quality automobile water pump is a testament to precision engineering, involving a meticulous sequence of advanced processes. At YD Castings, we adhere to the most rigorous standards, including ISO 9001 and IATF 16949, to ensure every component meets and exceeds industry expectations for performance and durability. Our commitment to quality starts from raw material selection and extends through every stage of production.

Design & Prototyping

The journey begins with comprehensive CAD/CAM design. Our engineers use advanced simulation software (e.g., CFD for fluid dynamics, FEA for stress analysis) to optimize impeller blade geometry for maximum flow and efficiency, and to design robust housings. Rapid prototyping techniques like 3D printing are employed to create initial models for fitment and preliminary testing, ensuring that the final automobile water pump design is optimized for specific vehicle platforms and cooling demands, including integration with complex engine manifolds.

Material Selection & Preparation

Choosing the right material is paramount for a long-lasting automobile water pump. We primarily use high-grade aluminum alloys (e.g., A356, A380 for housings due to their excellent castability, thermal conductivity, and lightweight properties), ductile iron for specific heavy-duty applications, and high-strength plastics for impellers in electric pump designs (e.g., PPS, PPA reinforced with glass fibers for corrosion resistance and reduced inertia). Raw materials undergo stringent incoming quality control, including spectroscopic analysis and mechanical testing, to confirm their exact composition and properties.

Casting or Forging (for Housings)

For metallic housings, we employ advanced manufacturing processes:

- Die Casting: For high-volume production of intricate aluminum housings, die casting offers excellent dimensional accuracy, fine surface finish, and mechanical properties. Molten aluminum is injected under high pressure into steel molds.

- Investment Casting (Lost-Wax Casting): For complex geometries and superior surface finish, particularly for smaller batches or specialized designs, investment casting is used. This process ensures high precision and minimal post-casting machining.

- Sand Casting: For larger, less complex components or prototypes, sand casting provides a cost-effective solution, allowing for quick design iterations.

- Forging: In some heavy-duty or performance applications where extreme strength is required, forging might be used for certain components, providing superior grain structure and mechanical integrity.

CNC Machining & Finishing

After casting, components undergo precision CNC (Computer Numerical Control) machining. Multi-axis CNC machines mill critical surfaces, drill precise holes for mounting and fluid passages, and ensure tight tolerances for bearing seats and seal surfaces. This stage is crucial for achieving the required dimensional accuracy (e.g., within 0.02mm) and surface finish for optimal sealing and rotational balance. Automated optical inspection systems verify critical dimensions against CAD models.

Assembly & Integration

Cleanroom conditions are maintained for the assembly of sensitive components like bearings and mechanical seals. Automated assembly lines ensure consistent torque application and precise component placement. For automotive electric water pump units, the electric motor, control electronics, and impellers are meticulously integrated, ensuring seamless operation and precise flow control.

Rigorous Testing & Quality Control

Every automobile water pump undergoes a series of stringent tests to ensure peak performance and reliability:

- Leak Testing: Pressure decay tests or helium leak tests verify the integrity of seals and castings, ensuring no coolant leaks.

- Flow & Pressure Testing: Pumps are run on test benches to verify their flow rate and pressure head against design specifications across various RPMs (for mechanical) or power inputs (for electric).

- Durability & Lifespan Testing: Accelerated life cycle tests simulate years of operation under extreme conditions (temperature cycling, vibration, corrosive fluids) to validate the pump's expected lifespan and robustness. We aim for a service life exceeding 150,000 miles, translating to over 5,000 operating hours under normal conditions.

- Noise, Vibration, and Harshness (NVH) Testing: Especially crucial for electric pumps, NVH tests ensure quiet operation and minimal vibrations.

- End-of-Line Inspection: Visual inspections, dimensional checks, and functional tests are performed on every unit before packaging.

Surface Treatment & Packaging

Depending on the material and application, components may receive surface treatments like anodizing for corrosion resistance or specific coatings for enhanced wear protection. Finally, pumps are carefully packaged to prevent damage during transit, ready for global distribution.

Fig 2: A visual representation of the highly automated assembly line for automobile water pump units, showcasing precision robotics and quality control stations.

Application Scenarios & Industry Impact

The role of the automobile water pump extends far beyond conventional passenger vehicles. Its critical function in thermal management makes it indispensable across a vast array of industries and demanding application scenarios:

- Automotive (Passenger & Commercial Vehicles): From compact cars to heavy-duty trucks, the water pump is fundamental. In passenger cars, it ensures engine longevity and performance. For commercial vehicles, especially long-haul trucks and buses, robust pumps are required to handle sustained high loads and extreme operating environments. The increasing adoption of electric water pump for car and commercial vehicle applications is driven by the need for better fuel efficiency and thermal management for complex powertrains including hybrid and electric drive systems.

- Heavy Machinery & Off-Highway Equipment: Construction equipment (excavators, bulldozers), agricultural machinery (tractors, harvesters), and mining vehicles operate in harsh conditions, often with high ambient temperatures and heavy dust. Their engines require powerful and highly durable water pumps capable of consistent performance under extreme stress and vibration.

- Marine Applications: Marine engines, whether in recreational boats or commercial vessels, face unique challenges including exposure to saltwater (which necessitates excellent corrosion resistance), continuous operation, and often confined spaces. Specialized marine automobile water pump designs are engineered to withstand these corrosive environments and deliver reliable cooling.

- Power Generation: Diesel and gas generators, used for primary or backup power in diverse settings (from data centers to remote construction sites), rely on efficient cooling systems. Industrial-grade water pumps ensure these engines operate within safe temperature limits, preventing downtime and ensuring continuous power supply.

- Industrial Equipment: Various industrial engines, compressors, and hydraulic power units in sectors like petrochemicals, metallurgy, and general manufacturing require dedicated cooling solutions. The pumps used here must often handle high-volume flow, operate continuously, and be resistant to specific industrial fluids or airborne contaminants.

Advantages in Typical Application Scenarios:

- Energy Efficiency (especially Automotive Electric Water Pump): In modern vehicles, an auto electric water pump can be precisely controlled, consuming power only when needed. This contrasts with mechanical pumps that continuously draw power from the engine, leading to fuel savings of up to 5% in certain driving conditions and enabling faster engine warm-up, reducing emissions.

- Corrosion Resistance: For marine or industrial applications, pumps made from advanced stainless steels, bronze, or specially coated aluminum alloys offer superior resistance to corrosive agents, significantly extending lifespan in challenging environments like those found in the petrochemical or wastewater treatment industries.

- Durability in Harsh Environments: Through robust bearing design, high-quality seals (e.g., silicon carbide mechanical seals), and precision casting, our automobile water pump products exhibit exceptional resilience against vibration, thermal cycling, and abrasive particles often encountered in mining or construction.

- Quiet Operation: The advent of the electric water pump for car and other electric vehicle applications has made quiet operation a key advantage. With no mechanical belt drive, these pumps significantly reduce NVH (Noise, Vibration, and Harshness) levels, enhancing passenger comfort.

- Integration with Engine Manifolds: Modern engine designs often integrate components like the water pump directly into the engine's architecture, sometimes even within or directly adjacent to complex engine manifolds. This requires precise manufacturing and tight tolerances to ensure proper fitment and sealing, preventing coolant leaks and optimizing space utilization.

Technical Advantages & Innovation at YD Castings

At YD Castings, our expertise in manufacturing extends to producing superior automobile water pump components and complete assemblies that offer significant technical advantages. Our commitment to innovation ensures our products not only meet but often exceed the demanding requirements of the automotive and industrial sectors.

- Precision Engineering and Tight Tolerances: Leveraging state-of-the-art CNC machining and advanced casting techniques, we achieve exceptionally tight dimensional tolerances (e.g., ±0.01mm on critical features). This precision is vital for minimizing internal leakage, optimizing impeller efficiency, and ensuring perfect fitment within complex engine architectures, particularly around sensitive areas like the engine manifolds.

- Optimized Hydrodynamic Design: Our R&D team utilizes computational fluid dynamics (CFD) to design impeller and volute geometries that maximize flow rate and pressure head while minimizing cavitation and turbulence. This results in highly efficient pumps that reduce parasitic losses and ensure effective cooling even under extreme operating conditions. This is particularly crucial for the development of high-performance automotive electric water pump systems.

- Advanced Material Science: We select and process materials for specific applications to enhance performance. For instance, using lightweight, high-strength aluminum alloys (like AlSi10Mg) for housings reduces overall vehicle weight, contributing to fuel economy. For impellers, we might use glass-fiber reinforced thermoplastics (e.g., Ryton® PPS) that offer superior chemical resistance to coolants and excellent dimensional stability under high temperatures, surpassing the performance of conventional plastic or stamped metal impellers.

- Superior Sealing Technology: The mechanical seal is the most common point of failure for water pumps. We integrate advanced mechanical seals, often utilizing silicon carbide (SiC) or aluminum oxide (Al2O3) faces for exceptional wear resistance and durability, especially when exposed to abrasive particles or aggressive coolants. This extends the service life of the automobile water pump significantly.

- Robust Bearing Systems: High-quality, permanently lubricated ball bearings or roller bearings are selected based on anticipated load, speed, and temperature conditions. We employ specialized manufacturing processes to ensure precise bearing seat machining, minimizing vibration and noise while maximizing bearing life.

- Integration of Smart Technologies (for Electric Pumps): Our electric water pump for car solutions often incorporate integrated control electronics (ECUs) that allow for variable speed control, diagnostic capabilities, and communication with the vehicle's central control unit. This intelligent control enables precise thermal management, optimizes power consumption, and provides real-time feedback on pump status.

- Corrosion and Cavitation Resistance: Through careful material selection and design, our pumps exhibit excellent resistance to corrosion from modern coolants and cavitation erosion, which can degrade impeller performance over time. This ensures consistent performance and a longer operational life.

Fig 3: An illustration showcasing the advanced fluid dynamics analysis (CFD) used in optimizing impeller design for maximum flow efficiency in an automobile water pump.

Manufacturer Comparison & YD Castings' Competitive Edge

The global market for automobile water pump solutions is highly competitive, featuring numerous manufacturers ranging from large multinational corporations to specialized regional suppliers. While many offer standard products, YD Castings distinguishes itself through a unique blend of core competencies that deliver exceptional value and performance.

General Manufacturer Landscape:

Most manufacturers typically focus on mass production, often prioritizing cost efficiency and broad market coverage. Their strengths may include:

- Standardized Products: A wide range of off-the-shelf pumps designed for common vehicle models.

- Economies of Scale: Ability to produce large volumes at competitive prices.

- Broad Distribution Networks: Extensive aftermarket presence.

However, these manufacturers often face limitations in:

- Customization: Limited flexibility for unique specifications or highly specialized applications.

- Advanced Material Application: Sticking to conventional materials to keep costs down.

- Precision for Niche Applications: May not meet ultra-high precision requirements for high-performance or next-generation vehicle systems.

- Integrated Solutions: Less likely to offer comprehensive design-to-production partnership for complex thermal management systems.

YD Castings' Competitive Edge:

YD Castings' approach is rooted in advanced engineering, stringent quality control, and a customer-centric philosophy. We position ourselves as a preferred partner for clients demanding precision, durability, and customized solutions.

| Feature/Advantage | Typical Manufacturer | YD Castings' Advantage |

|---|---|---|

| Product Focus | Standard, mass-produced replacements. | High-performance, OEM-grade, and custom-engineered automobile water pump solutions. |

| Design & Engineering | Reverse engineering, incremental improvements. | Proactive R&D, advanced CFD/FEA simulation, collaborative design partnership. |

| Material Quality | Standard alloys/plastics for cost-effectiveness. | Premium, application-specific materials (e.g., aerospace-grade aluminum, advanced thermoplastics for auto electric water pump). |

| Manufacturing Precision | General industry tolerances. | Tightest tolerances (sub-micron for critical features), multi-axis CNC machining. |

| Quality Control | Batch testing, basic functional checks. | 100% component inspection, comprehensive functional testing (leak, flow, pressure, NVH, accelerated life cycle) for every unit, adherence to IATF 16949. |

| Customization Capabilities | Limited or expensive. | Extensive custom design, prototyping, and production based on client specifications and application needs, including specialized integration with engine manifolds. |

| Technical Support | Standard customer service. | Dedicated engineering support, application specialists, post-sales technical assistance. |

| Certifications | ISO 9001 (basic). | ISO 9001, IATF 16949 (Automotive Quality Management System), adherence to industry standards like ANSI/HI. |

| Lifespan & Durability | Meets basic vehicle warranty. | Exceeds OEM requirements, designed for extended vehicle life (often 150,000+ miles/5,000+ hrs). |

Customized Solutions & Engineering Partnership

In today's highly specialized automotive and industrial landscapes, off-the-shelf solutions often fall short of optimal performance. YD Castings excels in providing bespoke automobile water pump solutions, acting as an extended engineering arm for our clients. Our customized approach ensures that every pump is perfectly aligned with the unique demands of its application, from high-performance racing engines to specialized industrial machinery.

Our Customization Process:

- Initial Consultation & Requirements Gathering: We begin by deeply understanding your specific needs. This includes detailed discussions on application environment (temperature, vibration, fluid type), desired performance parameters (flow rate, pressure head), space constraints (especially crucial around compact engine manifolds), power source (mechanical vs. automotive electric water pump), expected lifespan, and specific industry standards.

- Feasibility Study & Conceptual Design: Our engineering team conducts a thorough feasibility study, proposing initial concepts and material choices. We leverage our extensive knowledge of casting, forging, and CNC machining capabilities to determine the most efficient and effective manufacturing path.

- Advanced Engineering & Simulation: Utilizing cutting-edge software for CFD (Computational Fluid Dynamics) for fluid flow optimization and FEA (Finite Element Analysis) for structural integrity, we refine the pump design. This iterative process ensures the design will perform optimally under real-world conditions, minimizing prototypes and accelerating development. This is especially vital for complex auto electric water pump systems where precise control and thermal management are paramount.

- Prototyping & Validation: Once the design is finalized, prototypes are manufactured using the chosen production methods. These prototypes undergo rigorous in-house testing (flow, pressure, leak, NVH, accelerated life testing) as well as client-specific validation tests to ensure all performance metrics are met.

- Tooling Design & Production Setup: Upon successful validation, our team designs and manufactures the necessary tooling (molds for casting, fixtures for machining). We establish a dedicated production line, ensuring adherence to strict quality protocols at every step.

- Volume Production & Ongoing Support: With production underway, we maintain continuous quality monitoring. Our partnership doesn't end with delivery; we offer ongoing technical support, spare parts, and can adapt production to evolving requirements or future design iterations.

Example: Custom Automotive Electric Water Pump for a New EV Platform

A leading electric vehicle manufacturer approached YD Castings requiring a custom auto electric water pump for their new generation battery thermal management system. The challenge was to deliver a pump that was ultra-compact, highly efficient, and capable of variable flow rates from 0-100 LPM with extremely low noise (below 40 dB) and a targeted lifespan of 200,000 miles. We developed a unique brushless DC motor-driven pump with an integrated CAN bus communication module. The impeller and housing were designed using lightweight, corrosion-resistant polymers, significantly reducing weight while ensuring precise flow control essential for battery temperature regulation. The client achieved a 15% improvement in thermal efficiency and reduced vehicle weight by 2kg per pump, contributing to extended battery range.

Application Case Studies

Our commitment to excellence and customization is best illustrated through real-world applications where YD Castings' automobile water pump solutions have delivered measurable improvements and solved complex engineering challenges.

Case Study 1: High-Performance Sports Car Cooling System Optimization

Client Challenge: A boutique sports car manufacturer needed to upgrade the cooling system for their next-generation V8 engine. The existing mechanical water pump struggled to provide adequate cooling during sustained track use, leading to power derating and reduced engine longevity. The new pump needed to deliver higher flow rates, be lighter, and integrate seamlessly into an already compact engine bay with tightly packed engine manifolds.

YD Castings Solution: We engineered a high-flow, lightweight automotive electric water pump solution. Our team utilized advanced aluminum die casting for the pump housing to achieve optimal strength-to-weight ratio and rapid heat dissipation. The impeller was custom-designed using CFD analysis to maximize flow efficiency (achieving 20% higher flow at peak RPM compared to the old pump) while being fabricated from a high-strength, low-inertia polymer. The pump incorporated an intelligent control unit that communicated with the car's ECU, enabling demand-based cooling and eliminating parasitic losses at low engine speeds. This enabled faster engine warm-up and reduced emissions.

Results: The new automobile water pump allowed the engine to maintain optimal operating temperatures even under extreme track conditions, eliminating power derating and increasing engine reliability. The weight reduction contributed to overall vehicle performance, and the precise control of the electric pump improved fuel efficiency by 3% in mixed driving cycles.

Case Study 2: Industrial Pump for Aggressive Chemical Environments

Client Challenge: A large petrochemical plant required a replacement pump for a critical cooling loop that circulated a mildly corrosive industrial fluid. Previous pumps failed prematurely due to chemical erosion and cavitation. The operational environment was continuous, with high temperatures and significant vibration.

YD Castings Solution: We designed a robust industrial-grade automobile water pump (adapted from our heavy-duty automotive range for its inherent durability) specifically tailored for this application. Key modifications included using a specialized stainless steel alloy (Duplex 2205) for the impeller and housing, known for its superior corrosion resistance. The mechanical seal was upgraded to a high-performance silicon carbide-silicon carbide pairing, rated for aggressive media and high temperatures. Furthermore, the bearing system was enhanced with heavy-duty, sealed-for-life bearings designed to withstand continuous high load and vibration. Our manufacturing process, including precision CNC machining and rigorous pressure testing, ensured absolute leak integrity and long-term performance.

Results: The customized pump delivered a lifespan of over 5 years, significantly exceeding the 1.5-year average of previous pumps, leading to substantial reductions in maintenance costs and critical downtime for the plant. Its robust construction and material selection effectively combated corrosion and cavitation, maintaining consistent flow rates under demanding conditions, proving that the principles used in a durable automobile water pump can extend to diverse industrial applications.

Fig 4: A YD Castings engineer conducting rigorous performance testing on an automobile water pump on a dynamometer, ensuring adherence to flow rate and pressure specifications.

Quality Assurance, Certification & Industry Authority

At YD Castings, quality is not just a department; it's an ingrained culture and a fundamental principle guiding every aspect of our operations. Our commitment to delivering superior automobile water pump products is underpinned by comprehensive quality assurance protocols, industry-leading certifications, and a proven track record that establishes our authority in precision manufacturing.

Our Quality Management System:

- ISO 9001 Certified: Our overarching Quality Management System (QMS) is certified to ISO 9001, demonstrating our ability to consistently provide products and services that meet customer and regulatory requirements. This forms the foundation of our structured approach to quality.

- IATF 16949 Certified: Specifically for the automotive sector, we are IATF 16949 certified. This is the highest global standard for automotive quality management, requiring rigorous process control, continuous improvement, defect prevention, and reduction of variation and waste in the supply chain. It signifies our capability to serve as a Tier 1 or Tier 2 supplier to major automotive OEMs for components like the automobile water pump and engine manifolds.

- Comprehensive In-Process & Final Inspection:

- Incoming Material Inspection: All raw materials (e.g., aluminum ingots, steel bars, plastic resins) undergo thorough inspection and testing (chemical composition analysis, mechanical properties verification) before being accepted into production.

- First Article Inspection (FAI): The first part off any new tool or setup undergoes a complete dimensional and visual inspection to ensure it meets all specifications.

- In-Process Control: Throughout casting, machining, and assembly, statistical process control (SPC) techniques are employed. Critical dimensions are monitored using CMMs (Coordinate Measuring Machines), optical scanners, and specialized gauges to ensure consistency.

- Functional Testing: Every single automobile water pump unit undergoes functional testing on dedicated test benches. This includes leak testing, flow rate and pressure head verification, and in the case of an automotive electric water pump, electrical performance and control signal validation.

- Destructive & Non-Destructive Testing (NDT): Batch samples undergo destructive tests (e.g., tensile strength, hardness, fatigue testing) and non-destructive tests (e.g., X-ray inspection for internal defects in castings, ultrasonic testing) to ensure material integrity and structural soundness.

- Continuous Improvement (Kaizen): We actively implement Lean manufacturing principles and Kaizen methodologies. Our teams are continuously identifying opportunities to enhance process efficiency, reduce waste, and further improve product quality, fostering a culture of excellence.

Industry Partnerships & Authoritative Standing:

- Long-standing OEM Partnerships: We have established enduring partnerships with several leading automotive manufacturers and Tier 1 suppliers, demonstrating their trust in our consistent quality and reliable delivery of components, including complex assemblies like engine manifolds and sophisticated **automobile water pump** systems.

- Adherence to Global Standards: Beyond ISO and IATF, our products are designed and tested to comply with relevant industry standards such as ANSI/HI (American National Standards Institute / Hydraulic Institute) for pump performance metrics, and specific automotive component testing standards (e.g., those governing vibration, thermal shock, and chemical compatibility for the **auto electric water pump**).

- Years of Service & Experience: With decades of experience in precision casting and machining for the automotive sector, YD Castings brings unparalleled expertise. Our longevity in the industry is a testament to our adaptability, technological advancement, and unwavering commitment to quality.

Third-Party Standard Compliance & Testing

Our commitment to excellence is not self-proclaimed. We regularly subject our products to independent third-party validation. For example, specific batches of our **automobile water pump** units undergo lifecycle testing at accredited laboratories, which typically involves running pumps continuously under simulated real-world conditions for extended periods (e.g., 5,000 hours or more). These tests rigorously verify the product's adherence to standards like SAE J1508 for hose clamps used in cooling systems or specific OEM durability standards. This external verification adds an additional layer of confidence and strengthens our claim as an authoritative and trustworthy supplier.

Trust & Support: Your Partner in Automotive Excellence

Building strong, trustworthy relationships with our clients is at the core of YD Castings' philosophy. We understand that acquiring critical components like the automobile water pump is more than just a transaction; it's about securing a reliable supply chain and ensuring long-term operational success. Our comprehensive support framework is designed to provide peace of mind, from initial inquiry to post-delivery service.

Transparent Delivery Cycle:

We pride ourselves on clear communication regarding our production and delivery timelines. While exact lead times can vary based on the complexity of the automobile water pump design, material availability, and order volume, our typical delivery cycle involves:

- Standard Production: For established designs and recurring orders, lead times are typically 4-6 weeks from order confirmation to shipment.

- Custom Projects/New Tooling: For bespoke **automobile water pump** solutions requiring new tooling and extensive prototyping, the process typically spans 12-16 weeks for initial samples, followed by standard production lead times once samples are approved.

- Expedited Options: For urgent requirements, we offer expedited manufacturing and shipping options where feasible, leveraging our flexible production lines to meet tight deadlines. We utilize robust logistics networks to ensure timely and secure global delivery.

Our project managers provide regular updates throughout the production process, ensuring you are always informed about your order's status.

Comprehensive Quality Assurance & Warranty Commitment:

Every automobile water pump manufactured by YD Castings undergoes rigorous multi-stage quality control. We back the quality and durability of our products with a robust warranty. Our standard warranty covers defects in material and workmanship for a period of [2 years or 100,000 miles, whichever comes first] from the date of purchase. For specific OEM or industrial applications, customized warranty agreements can be negotiated to align with project requirements and expected operational life, reflecting our confidence in our high-quality components like the **auto electric water pump** and sturdy **engine manifolds**.

Should any issue arise, our dedicated support team is ready to investigate, troubleshoot, and provide prompt resolutions, ensuring minimal disruption to your operations. We believe in standing behind our products.

Unparalleled Customer Support:

- Dedicated Account Management: Each client is assigned a dedicated account manager who serves as a single point of contact for all inquiries, from order placement to technical support.

- Technical Support & Engineering Assistance: Our team of experienced engineers is available to provide in-depth technical assistance, whether it's for product selection, installation guidance, troubleshooting, or understanding the nuances of how a particular **automobile water pump** interacts with a cooling system.

- After-Sales Service: We offer comprehensive after-sales support, including handling warranty claims, facilitating returns or exchanges, and providing maintenance advice to maximize product lifespan.

- Spare Parts Availability: We maintain an inventory of critical spare parts for our products, ensuring quick access for maintenance or repairs, minimizing downtime for our clients.

- Global Reach, Local Expertise: While we serve a global clientele, our customer support is tailored to provide personalized service, understanding regional requirements and logistical nuances.

Frequently Asked Questions (FAQ) about Automobile Water Pumps

1. What is the primary function of an automobile water pump?

The primary function of an automobile water pump is to circulate coolant through the engine's cooling system. This continuous circulation helps dissipate the heat generated by the engine during combustion, maintaining optimal operating temperatures and preventing overheating, which can lead to severe engine damage.

2. What is the difference between a mechanical and an automotive electric water pump?

A mechanical automobile water pump is typically belt-driven by the engine's crankshaft, meaning its speed is directly tied to engine RPM. An automotive electric water pump, or **auto electric water pump**, is powered by an electric motor and can be controlled independently of engine speed. This allows for more precise, on-demand cooling, improved fuel efficiency, and faster engine warm-up.

3. What materials are typically used to manufacture an automobile water pump?

Common materials include cast iron or aluminum alloys (e.g., A356, A380) for the pump housing, steel or stainless steel for the shaft, and stamped steel, cast iron, or various reinforced plastics (like PPS, PPA) for the impeller. Advanced mechanical seals often use silicon carbide or aluminum oxide for durability.

4. What are the signs of a failing automobile water pump?

Common signs of a failing automobile water pump include: coolant leaks (often from the weep hole), an overheating engine, a whining or grinding noise coming from the pump (indicating bearing failure), or steam emanating from under the hood. Rust or corrosion near the pump can also be an indicator.

5. How long does an automobile water pump typically last?

The lifespan of an **automobile water pump** varies significantly based on its quality, type (mechanical vs. electric), and operating conditions. High-quality OEM-grade mechanical pumps typically last between 100,000 to 150,000 miles (approx. 3,000-5,000 operating hours). Modern electric water pump for car applications are often designed for an even longer lifespan, potentially exceeding 150,000-200,000 miles (5,000-7,000+ hours).

6. Can a faulty water pump damage other engine components?

Absolutely. A failing automobile water pump can lead to rapid engine overheating, which can cause severe and irreversible damage to critical engine components such as the cylinder head gasket (blown head gasket), engine block, pistons, and valves. It can also lead to premature wear of connected components like drive belts and bearings.

7. How does the automobile water pump interact with engine manifolds?

While the water pump directly circulates coolant through the engine block and cylinder head, some modern engine designs, particularly those with complex thermal management, might have coolant passages that run through or very near the engine manifolds (intake or exhaust) for heating or cooling purposes (e.g., to heat intake air for better combustion or cool exhaust gases for emissions). The water pump's efficient circulation ensures that these integrated passages receive adequate coolant flow, contributing to overall engine thermal stability and performance, especially in turbocharged engines.

Conclusion

The automobile water pump, though often overlooked, remains a cornerstone of vehicle performance and longevity. From its fundamental role in internal combustion engines to its evolving significance in the age of electrification and advanced thermal management, its design, manufacturing, and reliability are paramount. As vehicle systems become more sophisticated, the demand for high-precision, durable, and energy-efficient cooling solutions, including advanced automotive electric water pump and **auto electric water pump** technologies, will only intensify.

At YD Castings, we are not just manufacturers; we are innovators and partners. Our deep expertise in material science, advanced casting, precision CNC machining, and rigorous quality control (certified to IATF 16949) enables us to deliver automobile water pump and **automobile accessories** solutions that set industry benchmarks. Whether you require a standard replacement part, a highly customized pump for a unique application, or a strategic engineering partner for next-generation thermal systems integrated with complex **engine manifolds**, we are equipped to exceed your expectations. Our commitment to excellence, transparency, and unwavering customer support ensures that when you choose YD Castings, you are choosing reliability and performance that drives success.

References & Further Reading:

- MarketsandMarkets Report. "Electric Water Pump Market by Type, Vehicle Type, Material Type, Application, and Region - Global Forecast to 2027." https://www.marketsandmarkets.com/Market-Reports/electric-water-pump-market-267924739.html

- SAE International Journal of Engines. "Optimizing Engine Warm-Up and Fuel Economy Through Controlled Electric Water Pumps." *SAE Technical Paper 2012-01-0818*. https://www.sae.org/publications/technical-papers/content/2012-01-0818/

- Hydraulic Institute. "ANSI/HI 9.6.1-2017 Rotodynamic Pumps - Guidelines for Flows and Pressures." https://estore.pumps.org/ANSI-HI-9.6.1-2017-Rotodynamic-Pumps-Guidelines-for-Flows-and-Pressures_p_348.html

- "The Evolution of Automotive Thermal Management Systems." *Automotive IQ Whitepaper*. https://www.automotiveiq.com/powertrain/whitepapers/the-evolution-of-automotive-thermal-management-systems

-

How to Inspect Pump Cap Ends for DamageNewsNov.21,2025

-

Backward Curved Impeller – Efficient Airflow Solutions for Industry | YD CastingsNewsNov.21,2025

-

Automobile Water Pump - Efficient, Quiet, Durable & ElectricNewsNov.21,2025

-

Impeller for Pumps – High-Efficiency, Durable, OEM-ReadyNewsNov.21,2025

-

Essential Insights on Plug End Caps for Industrial EquipmentNewsNov.21,2025

-

Quality Inspection of Valve BodyNewsNov.21,2025