Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Jan . 10, 2025 13:08

Back to list

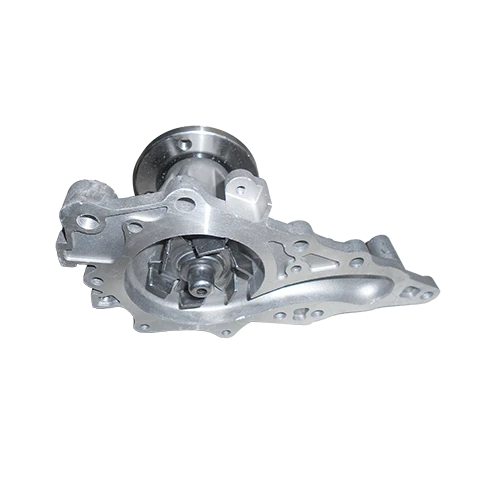

pump casing

Navigating the complex world of water pump casing can be daunting, yet understanding its intricacies is crucial for anyone seeking to optimize the performance and longevity of their water pump systems. This guide dives deep into the essential aspects of water pump casing, combining practical experience with professional expertise to provide a comprehensive understanding that is both authoritative and trustworthy.

Authoritative sources highlight the evolution of water pump casing technology, particularly the shift towards environmentally friendly materials and design practices. Manufacturers are now experimenting with composite materials that offer a balance between strength, weight, and environmental impact. Such advancements promise reductions in energy consumption and an overall enhancement in system sustainability. Trustworthiness in water pump casing selection and maintenance is further reinforced by adherence to industry standards and certifications. Recognitions such as ISO 9001 for quality management systems and ASME standards for pressure integrity validate the reliability and safety of the casings. These certifications provide end-users with peace of mind, knowing their systems are built and maintained to the highest quality standards. In conclusion, mastering the domain of water pump casing involves a blend of technical expertise, continuous learning, and adherence to high industry standards. By understanding the material properties, engineering considerations, and maintenance protocols, stakeholders can make informed decisions that enhance the performance and longevity of their water pump systems. This article not only equips readers with the necessary knowledge but also instills confidence in their ability to manage and maintain efficient pumping operations.

Authoritative sources highlight the evolution of water pump casing technology, particularly the shift towards environmentally friendly materials and design practices. Manufacturers are now experimenting with composite materials that offer a balance between strength, weight, and environmental impact. Such advancements promise reductions in energy consumption and an overall enhancement in system sustainability. Trustworthiness in water pump casing selection and maintenance is further reinforced by adherence to industry standards and certifications. Recognitions such as ISO 9001 for quality management systems and ASME standards for pressure integrity validate the reliability and safety of the casings. These certifications provide end-users with peace of mind, knowing their systems are built and maintained to the highest quality standards. In conclusion, mastering the domain of water pump casing involves a blend of technical expertise, continuous learning, and adherence to high industry standards. By understanding the material properties, engineering considerations, and maintenance protocols, stakeholders can make informed decisions that enhance the performance and longevity of their water pump systems. This article not only equips readers with the necessary knowledge but also instills confidence in their ability to manage and maintain efficient pumping operations.

Next:

Latest news

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025

Related PRODUCTS