Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Feb . 18, 2025 11:05

Back to list

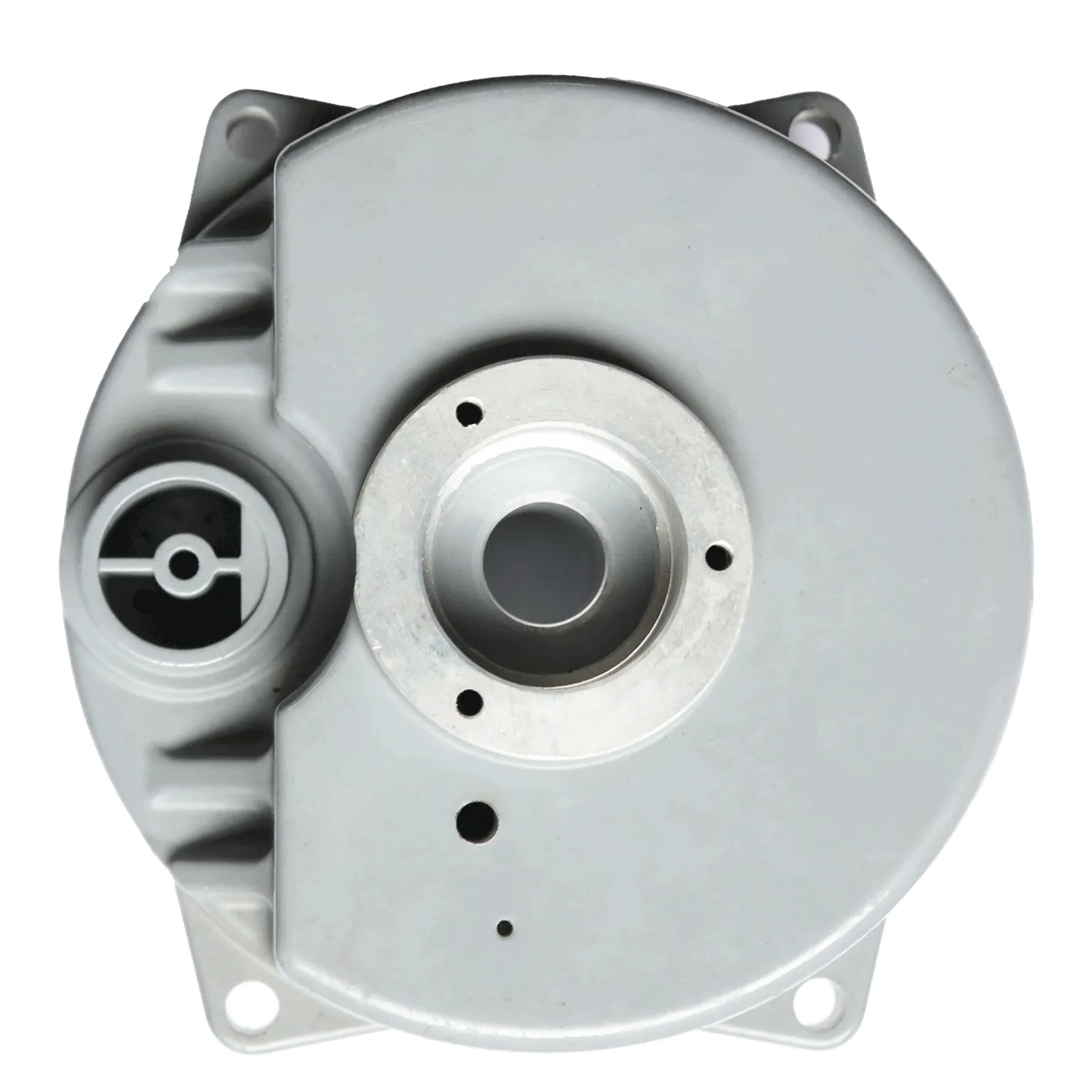

Automobile water pump shell

Pump rubber flex connectors are an essential component in many industrial and commercial fluid processing systems. With their unique design, these connectors provide flexibility, absorb vibration, and accommodate movement, which can significantly extend the lifespan of connected equipment. The selection of a suitable pump rubber flex connector involves understanding the material properties, design specifications, and operational requirements to ensure optimal performance.

Installation plays an equally essential part in maximizing the utility of pump rubber flex connectors. Proper installation techniques include ensuring the connector is not twisted, excessively stretched, or compressed, as these could impede its performance and cause premature failure. The alignment of the connecting flanges is crucial for preventing unnecessary stress on the connector. Using the correct type of fasteners and following the torque specifications as per the manufacturer’s guidelines will ensure a secure and lasting installation. Longevity and maintenance considerations are also factors in evaluating the TCO (Total Cost of Operation) of these connectors. Regular inspections and maintenance are necessary to detect signs of wear or degradation early. Replacing connectors at the first sign of cracks, leaks, or reduced flexibility can prevent more major system failures and costly downtimes. Choosing high-quality connectors from reputable manufacturers can enhance reliability and extend service life, providing better value and performance over time. Innovative advancements in material science and design continue to expand the capabilities of pump rubber flex connectors. New composites offer improved durability and resistance to environmental stresses, meeting the demanding requirements of modern industrial applications. As energy efficiency and sustainability become more critical, these connectors are evolving to meet stricter standards, reducing emissions and maintaining high-performance efficiency. In conclusion, pump rubber flex connectors are a pivotal component in enhancing the reliability and efficiency of fluid processing systems. Their ability to manage misalignments, vibrations, and thermal expansion not only protects equipment but also optimizes operational performance. Understanding the nuances of material properties, design choices, and installation guidelines ensures that these connectors provide the anticipated benefits and align with the demanding needs of various industries.

Installation plays an equally essential part in maximizing the utility of pump rubber flex connectors. Proper installation techniques include ensuring the connector is not twisted, excessively stretched, or compressed, as these could impede its performance and cause premature failure. The alignment of the connecting flanges is crucial for preventing unnecessary stress on the connector. Using the correct type of fasteners and following the torque specifications as per the manufacturer’s guidelines will ensure a secure and lasting installation. Longevity and maintenance considerations are also factors in evaluating the TCO (Total Cost of Operation) of these connectors. Regular inspections and maintenance are necessary to detect signs of wear or degradation early. Replacing connectors at the first sign of cracks, leaks, or reduced flexibility can prevent more major system failures and costly downtimes. Choosing high-quality connectors from reputable manufacturers can enhance reliability and extend service life, providing better value and performance over time. Innovative advancements in material science and design continue to expand the capabilities of pump rubber flex connectors. New composites offer improved durability and resistance to environmental stresses, meeting the demanding requirements of modern industrial applications. As energy efficiency and sustainability become more critical, these connectors are evolving to meet stricter standards, reducing emissions and maintaining high-performance efficiency. In conclusion, pump rubber flex connectors are a pivotal component in enhancing the reliability and efficiency of fluid processing systems. Their ability to manage misalignments, vibrations, and thermal expansion not only protects equipment but also optimizes operational performance. Understanding the nuances of material properties, design choices, and installation guidelines ensures that these connectors provide the anticipated benefits and align with the demanding needs of various industries.

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS