Móvil:+86-311-808-126-83

Correo electrónico:info@ydcastings.com

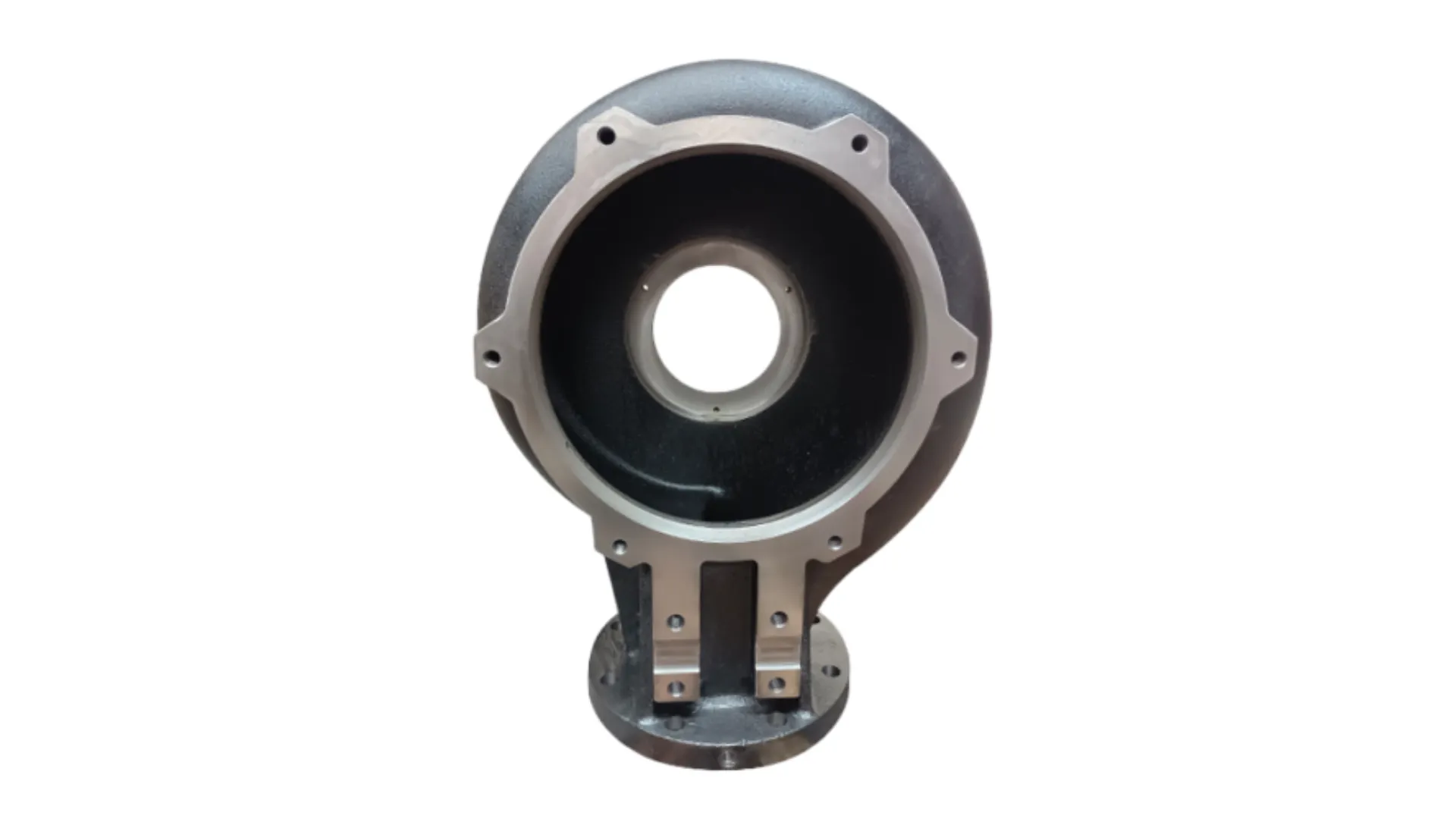

Product parameters

-

Material cast iron GG25, GGG40

-

Wall thickness 10-15mm

-

Weight 10-1500kg

-

Application areas: water supply system, heating system, drainage system, agricultural irrigation Customized products according to customer's drawing.

Product requirements

-

Uniform wall thickness

No leakage under pressure

-

Uniform surface

Welding repair is not allowed

-

The product is an internal cavity structure, which requires a core to complete the molding. Because the wall thickness of the product is small and the external dimension is large, so how to ensure that the wall thickness of the product is uniform is one of the difficulties in the production of the product.

-

For this reason, we in the mold design stage, the product involved in the positioning of the core made full consideration. Both to ensure the accuracy of the axial direction, but also need to consider the stability of the horizontal direction. In order to ensure that the cavity in all directions of the gap is consistent. This ensures that the wall thickness of the product is uniform.

-

In production, we use resin sand molding process. Resin sand has high strength and good air permeability. These characteristics are sufficient to ensure the stability of the cavity and air permeability. Thus, we can produce products that meet the quality requirements.

-

At the same time to ensure the wall thickness, we also analyze the product in the foot and pump body connection position there is a thermal node, if not handled properly, will produce internal casting defects to affect the service life of the product. Therefore, in the process arrangement, to take the appropriate increase in the necessary fill shrinkage risers, control the flow rate of liquid metal and other measures, in order to achieve uniform cooling contraction of the product, and thus avoid casting defects.

-

In order to make the product can have a uniform and consistent surface quality, we use high permeability refinement refractory coatings, this coating formed layer surface smooth and delicate, good permeability. The product is able to vent smoothly during the molding and cooling process while maintaining a smooth surface. The high-temperature-resistant property also makes the metal liquid completely isolated from the sand mold after entering the cavity, avoiding phenomena such as sand sticking.

-

Furthermore, the weight-to-volume ratio of the product is relatively small. Resin sand has the economy and high recyclability, which makes the product will have a relatively small cost investment in molding.

Performance

-

Cost-effectiveness: Due to the relatively low cost of cast iron materials, cast iron valves are more cost-effective and suitable for some occasions with strict requirements on cost.

-

Corrosion resistance: cast iron materials have good corrosion resistance for many chemical media, suitable for a variety of chemical and industrial applications. For example, the corrosion and oxidation resistance of ductile iron valves is superior to cast steel valves in some municipal applications3.

-

Casting performance: cast iron valves can be made into complex shapes by casting process, which is suitable for mass production. In addition, ductile iron valves are more efficient to cast and less expensive to machine23.

-

Temperature resistance: the temperature resistance of cast iron is not as good as that of stainless steel, and it is not suitable for use in high-temperature environments. Therefore, when choosing the valve body material, you need to decide whether to use cast iron valves or stainless steel valves according to the specific application requirements and working environment.

product advantages

-

High strength and low cost: cast iron has high strength, can withstand the role of high pressure, to ensure the normal operation of pumps and valves. At the same time, cast iron material prices are relatively low, making pumps and valves to reduce manufacturing costs, more market advantages.

-

Easy to process: cast iron texture is brittle, easy to process and handle, saving the manufacturing cost. Because of its relatively simple manufacturing process, molding is easy, manufactured pumps and valves have high stability and durability 1.

-

Good abrasion resistance and corrosion resistance: cast iron has good abrasion resistance and corrosion resistance, can be used in a variety of media, to maintain the normal service life of the pump. The corrosion resistance of cast iron makes it adapt to different working environments and extends the service life of pumps

Operation Scenario

-

Sewage treatment: due to the good abrasion and corrosion resistance of cast iron pumps, they are suitable for sewage treatment and other application scenarios that require the transportation of media containing solid particles.

-

Municipal applications: ductile iron valves excel in municipal applications, with better corrosion and oxidation resistance than cast steel valves, and are suitable for the control of water, salt water, steam and other media.

-

Chemical and industrial applications: cast iron valves and pumps are suitable for a wide range of chemical and industrial applications, able to cope with complex process requirements and working environment.

Contáctenos

Hebei Yuanda Trade Co., Ltd.(YD) was founded in 2006, devoted itself to provide flexible solutions for different needs of customized metal castings.

-

Materials Used in Manufacturing Cap End Pipe Fittings2024-03-12Materials Used in Manufacturing Cap End Pipe Fittings

Materials Used in Manufacturing Cap End Pipe Fittings2024-03-12Materials Used in Manufacturing Cap End Pipe Fittings -

-

-

Correo electrónico

-

Whatsapp

-

Arriba