Mobile:+86-311-808-126-83

Email:info@ydcastings.com

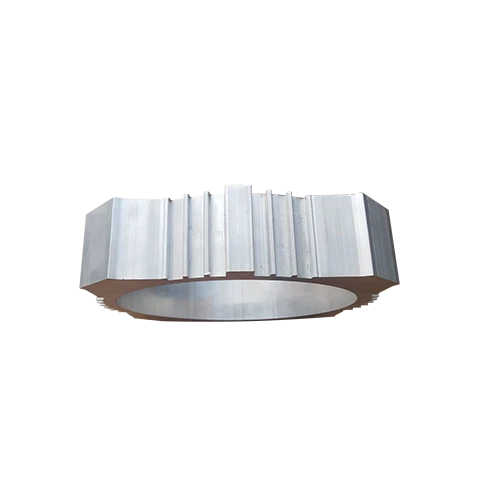

impeller

In the intricate world of fluid dynamics and mechanical engineering, the impeller stands as a pivotal component, transforming the way industries manage fluid flow. As the unsung hero in various systems, impellers are essential for enhancing efficiency and ensuring optimal performance in pumping technology. This article delves into the depth of impeller technology, highlighting its significance, advancements, and application across different sectors.

An impeller's design revolves around principles of centrifugal force, where fluid dynamics are utilized to convert mechanical input into kinetic energy, effectively moving liquids and gases. This process is crucial in applications ranging from water treatment facilities to the automotive industry. The efficiency of an impeller hinges on its design characteristics—blade shape, material composition, and the rotational speed—all meticulously engineered to maximize flow efficiency and minimize energy consumption. Recent advancements in impeller design have pushed the boundaries of efficiency and durability. Computers-Aided Design (CAD) and Computational Fluid Dynamics (CFD) have become indispensable tools, offering engineers the ability to simulate fluid dynamics and optimize the aerodynamic properties of impeller blades. Innovations in materials, such as high-performance polymers and advanced metal alloys, have led to the development of impellers that withstand extreme operational conditions, including high-temperatures and corrosive environments.

Industries such as chemical processing, medical equipment manufacturing, and HVAC systems have witnessed revolutionary changes with the integration of cutting-edge impeller technologies. In chemical plants, for example, precise impeller design ensures the accurate mixing of compounds, which is elemental in maintaining the consistency and quality of the final product. Moreover, the strategic pairing of impellers with variable frequency drives (VFDs) enables precise control over pump operations, ultimately reducing energy consumption and operational costs.impeller

Expert insights suggest that understanding the specific requirements of each application is fundamental when selecting an impeller. For high-viscosity applications, open impellers with fewer blades offer less resistance, thus allowing flow without clogging. Conversely, closed impellers are preferred for low-viscosity, clean fluids as they provide higher energy efficiency and are more capable of handling higher pressures.

Ensuring trust in impeller technology is heavily reliant on the continuous testing and validation of performance standards. Industry certifications such as ISO and ASME ensure that impeller manufacturing adheres to stringent quality and performance criteria. Furthermore, manufacturers often engage in rigorous testing, replicating operational scenarios to validate the lifespan and efficiency of their products.

It is crucial for companies to collaborate with experienced engineers who possess a deep understanding of fluid dynamics and mechanical systems to design impellers that meet specific operational needs. Such expertise not only ensures optimal performance but also prolongs the lifecycle of equipment, thereby reducing the need for frequent replacements and maintenance.

In conclusion, the impeller is not merely a component but a cornerstone in modern industrial applications. With continual advances in technology, impellers are set to become even more efficient, sustainable, and adaptable to various industry needs. As industries push towards greener and more sustainable solutions, the role of the impeller as a catalyst for energy efficiency and process innovation continues to grow, fostering a promising future for fluid management technologies.

-

Impeller Technology That Powers Precision in Pump SystemsNewsMay.22,2025

-

Valve Durability Begins with Quality Cast Iron ComponentsNewsMay.22,2025

-

Performance Cooling with Advanced Automobile Water Pump SolutionsNewsMay.22,2025

-

How Motor Housing and Oil Pans Shape Engine PerformanceNewsMay.22,2025

-

How Metal Castings Drive Modern Manufacturing EfficiencyNewsMay.22,2025

-

Exploring the Engineering Behind Valve Body CastingsNewsMay.22,2025