Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Ene . 09, 2025 10:35

Back to list

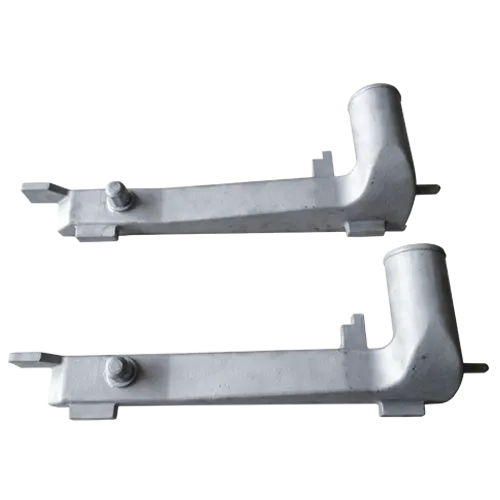

Connector bracket

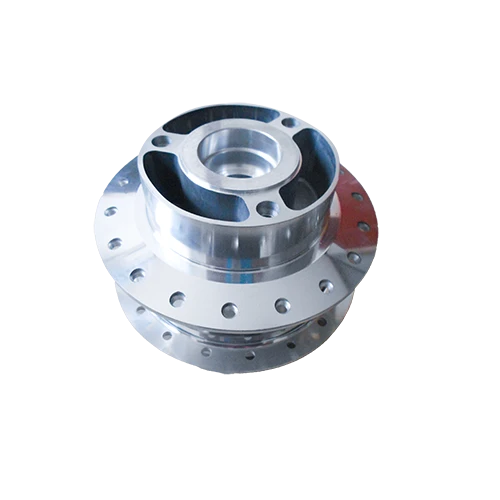

The impeller, a vital component in numerous applications, has been gaining significant attention in recent years due to its essential role in enhancing the efficiency and performance of various fluid-handling systems. The advanced design and engineering of impellers have revolutionized how industries manage flow processes, providing remarkable improvements in both energy consumption and operational efficiency.

The expertise required in the fabrication and maintenance of impellers cannot be understated. Professionals in the field stress the importance of regular inspections and maintenance schedules to preclude performance degradation over time. Optimal functionality demands precision balancing and alignment, aspects that only skilled technicians with comprehensive knowledge can guarantee. The implication of this on operational efficacy is profound, as improper maintenance of impellers can lead to catastrophic failures, causing damage to equipment and halting operations. Ensuring trustworthiness in impeller performance also requires adhering to industry standards and certifications, such as those from the Hydraulic Institute or ISO. Companies that prioritize these standards in their manufacturing processes provide assurances of quality and reliability, essential for industries where guaranteed performance and safety are paramount. Customers and stakeholders gain confidence knowing that products meet or exceed established benchmarks. For businesses looking to enhance their systems, selecting an impeller is not just about picking a product off the shelf; it's about partnering with manufacturers who demonstrate authoritativeness through a commitment to quality, research, and development. These manufacturers invest in state-of-the-art technology and foster a culture of innovation, ensuring they deliver products that are not only current with industry trends but also anticipatory of future demands. In conclusion, the role of impellers in advancing industrial fluid-handling processes is indisputable. The fusion of experience, expertise, authoritative knowledge, and unwavering trustworthiness in their design and maintenance underpins their critical importance across multiple sectors. Businesses aiming to leverage these facets gain a competitive edge, realizing savings, enhanced performance, and sustainability in their operations. As technology and material sciences continue to evolve, the future promises even more groundbreaking developments in impeller design, cementing their status as indispensable components in fluid dynamics.

The expertise required in the fabrication and maintenance of impellers cannot be understated. Professionals in the field stress the importance of regular inspections and maintenance schedules to preclude performance degradation over time. Optimal functionality demands precision balancing and alignment, aspects that only skilled technicians with comprehensive knowledge can guarantee. The implication of this on operational efficacy is profound, as improper maintenance of impellers can lead to catastrophic failures, causing damage to equipment and halting operations. Ensuring trustworthiness in impeller performance also requires adhering to industry standards and certifications, such as those from the Hydraulic Institute or ISO. Companies that prioritize these standards in their manufacturing processes provide assurances of quality and reliability, essential for industries where guaranteed performance and safety are paramount. Customers and stakeholders gain confidence knowing that products meet or exceed established benchmarks. For businesses looking to enhance their systems, selecting an impeller is not just about picking a product off the shelf; it's about partnering with manufacturers who demonstrate authoritativeness through a commitment to quality, research, and development. These manufacturers invest in state-of-the-art technology and foster a culture of innovation, ensuring they deliver products that are not only current with industry trends but also anticipatory of future demands. In conclusion, the role of impellers in advancing industrial fluid-handling processes is indisputable. The fusion of experience, expertise, authoritative knowledge, and unwavering trustworthiness in their design and maintenance underpins their critical importance across multiple sectors. Businesses aiming to leverage these facets gain a competitive edge, realizing savings, enhanced performance, and sustainability in their operations. As technology and material sciences continue to evolve, the future promises even more groundbreaking developments in impeller design, cementing their status as indispensable components in fluid dynamics.

Next:

Latest news

-

Why Should You Invest in Superior Pump Castings for Your Equipment?NewsJun.09,2025

-

Unlock Performance Potential with Stainless Impellers and Aluminum End CapsNewsJun.09,2025

-

Revolutionize Your Machinery with Superior Cast Iron and Aluminum ComponentsNewsJun.09,2025

-

Revolutionize Fluid Dynamics with Premium Pump ComponentsNewsJun.09,2025

-

Optimizing Industrial Systems with Essential Valve ComponentsNewsJun.09,2025

-

Elevate Grid Efficiency with High-Precision Power CastingsNewsJun.09,2025

Related PRODUCTS