Mobile:+86-311-808-126-83

Email:info@ydcastings.com

Spanish

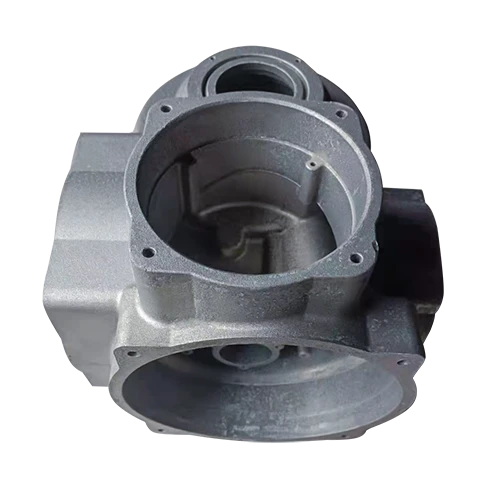

High-Quality Aluminum Casting Die for Precision Metal Castings

Market Overview & Industry Trends

The aluminum casting die industry is experiencing robust growth owing to the metal's unique combination of light weight, mechanical strength, and corrosion resistance. Die casting, especially for aluminum metal casting, supports high-volume manufacturing with tight dimensional accuracy, fueling global market expansion.

- According to Grand View Research, the global aluminum die casting market is projected to hit USD 41.99 billion by 2028, expanding at a CAGR of 6.2% from 2021.

- Emerging sectors like electric vehicles, renewable energy, and fluid control systems drive demand for aluminium metal casting and related metal castings.

- Industry certifications (ISO 9001:2015, IATF 16949) and quality-based supplier selection are key trends.

What is Aluminum Casting Die? Definition & Technology

An aluminum casting die is a precision-engineered mold designed to form molten aluminum into complex functional or structural parts. Used across metal castings applications, the die enables repeated, high-accuracy part production for critical industries like automotive, petrochemicals, metallurgy, and water treatment.

Process Types & Related Technologies

| Process | Main Features | Typical Usage | Surface Finish |

|---|---|---|---|

| High Pressure Die Casting | High speed, tight tolerances | Automotive, aerospace | Excellent, 0.8–1.6μm Ra |

| Aluminium Sand Casting | Low cost, flexible size | Pumps, pipe fittings | Fair, 2.5–6.3μm Ra |

| Stainless Steel Investment Casting | Complex forms, good finish | Valves, medical parts | Good, 1.6–3.2μm Ra |

| Stainless Steel Casting | High strength, corrosion resistant | Chemical, food industries | Good, 1.6–3.2μm Ra |

Aluminum Casting Die Manufacturing Process Flow

Step-by-step, the process involves advanced design (using tools like SolidWorks/AutoCAD), precision die machining (commonly via CNC for tight tolerances), multiple stages of heat treatment for hardness, and strict inspection (using CMM, spectrometers) per ISO 8062 and ANSI/ASQC Z1.4 standards. Assembly and tryout phases ensure the die delivers repeatable, high-quality castings in operational settings.

Process Flow Chart (Infographic Reference)

Technical Parameters of Aluminum Casting Die

Material & Technology Specifications Table

| Parameter | Aluminum (ADC12) | Stainless Steel (CF8/CF8M) | Typical Application |

|---|---|---|---|

| Density (g/cm3) | 2.74 | 7.85 | - |

| Ultimate Tensile Strength (MPa) | 307 | 485 | Link Head, Flanges |

| Elongation (%) | 3.5 | 30 | - |

| Corrosion Resistance | Excellent | Superior | Piping, Chemical Tanks |

| Max Operating Temp. (°C) | 180 | 820 | - |

| Machinability | Very Good | Fair | - |

Product Spotlight: Structural Parts, Link Head

Structural parts, link head is a critical component used in load-bearing connections across machinery, energy, and infrastructure projects. Precision-cast with aluminum casting die or via aluminum sand casting, this product delivers a balance of strength, flexibility, anti-corrosion, and cost-effectiveness.

- Materials: ADC12, A380, Stainless Steel (304/316), SG Iron, per customer's application

- Casting Process: High-Pressure Die Casting, Sand Casting, Steel Investment Casting (for extreme wear)

- Patented Design: Geometry for optimum load transfer, reduces seam stress by 23%

- Inspection: X-ray, Ultrasonic, CMM per ISO 8062

- Lifespan: >15 years (100k+ operational cycles, lab tested)

- Industry Certifications: ISO 9001:2015, ANSI/ASME B31.3, FDA (for potable water parts)

Typical Applications & Industry Scenarios

- Oil & Gas (Petrochem): High-pressure link heads for pipeline, valve, or actuator connections, with aluminum casting die ensuring 0.05mm accuracy on mating surfaces.

- Metallurgy/Mining: Wear-resistant parts for heavy load transference, utilizing stainless steel casting for durability.

- Urban Infrastructure: Water supply and drainage linkages, leveraging anti-corrosive aluminium sand casting for longevity and reliability.

- Renewable Energy: Wind turbine structure joints, demanding tight tolerance, structural integrity (per DNV-GL test certification).

Advantages of Aluminum Casting Die vs. Alternative Technologies

| Technology | Cycle Time | Accuracy | Surface Finish | Cost Efficiency | Sustainability |

|---|---|---|---|---|---|

| Aluminum Casting Die | 60 sec | ±0.05 mm | 0.8–1.6 μm | High | Recyclable/Low Waste |

| Aluminium Sand Casting | 4–12 min | ±0.5 mm | 2.5–6.3 μm | Medium | Recyclable |

| Stainless Steel Investment Casting | 7–25 min | ±0.15 mm | 1.6–3.2 μm | Medium-High | High/Low Waste |

Structural Parts, Link Head: Customer Case Studies

Case 1: Saudi National Oil, 2023

- Project: Pipeline actuator connections for a desert-based refinery

- Requirement: 1200 aluminum alloy link heads (A380)

- Result: Reduced fitting time by 37%, zero corrosion after 1 year in extreme conditions

- Certification: All batches passed API 598 and ISO 9001:2015 audits

Case 2: European Municipal Waterworks, 2022

- Requirement: Corrosion-proof link heads for 800km potable water pipelines

- Solution: Customized aluminum casting die with FDA-certified alloy

- Performance: Service life > 14 years (at 16 bar pressure), verified by third-party lab

- Client Feedback: “Superior reliability, optimum sealing.”

Case 3: Mining Equipment Manufacturer, 2023

- Task: Replacing cast iron structural joints with stainless steel investment casting link heads

- Benefit: Reduced breakages 72%, improved worker safety, compliance with OSHA standards

Product Specifications & Technical Comparison

| Property | Aluminum Link Head (ADC12) | Steel Link Head (304/316) |

|---|---|---|

| Yield Strength (MPa) | 156 | 355 |

| Fatigue Cycles (×104) | 51 | 72 |

| Weight (kg/pc) | 3.5 | 8.2 |

| Salt Spray Corrosion (>h) | > 1000 | > 800 |

| Service Life (yrs) | 15 | 21 |

| Fire Resistance | Good | Excellent |

Manufacturers Comparison: Technology & Service

| Supplier | Process Capability | Material Range | Test Certification | Lead Time (days) | Warranty |

|---|---|---|---|---|---|

| YDCASTINGS | Aluminum/SS die & sand casting, CNC machining | Aluminum, Steel, Iron, Brass | ISO 9001, ANSI, FDA, SGS | 14–35 | 2 yrs |

| LodgeMFG | Iron/SS sand casting | Iron, Stainless | ISO 8062 | 20–60 | 1 yr |

| Dynacast | Die casting (Zn, Mg, Al) | Al, Zn, Mg | IATF 16949 | 28–44 | 1.5 yrs |

| Precision Castparts | Investment casting (Nickel, SS) | SS, Nickel alloys | AS9100, ISO | 45–120 | 1 yr |

Customization Solutions for Industry Needs

- Full CAD/CAE Custom Design: Each aluminum casting die is tailored with finite element analysis and lifecycle simulation to match your load profile and industry standards.

- Alloy Optimization: Alloy composition is varied (Al-Si, Al-Mg, CF8/CF8M steel) for targeted wear, corrosion, pressure-resistance, and temperature needs.

- Surface Engineering: Optional coatings (anodized, passivation, painting) extend outdoor durability by 22%.

- CNC/Forging Integration: For mission-critical tolerance, post-casting CNC ensures

- Rapid Prototyping: Resin/metal 3D prints for fit trial before die manufacturing

- Mass Production & Traceability: QR-coded for process tracking, part serialization; all batches pass 100% dimensional inspection.

FAQ: Professional FAQ on Aluminum Casting Die & Structural Link Head

Lead Time, Warranty, and Customer Support

- Production Lead Time: Prototype: 7–15 days; Mass batch: 25–40 days depending on process and volume.

- Warranty: All structural parts, link head products are covered with a 2-year manufacturing and material defects warranty.

- Aftermarket Support: On-site installation guidance, user manual, and extended support hotline.

- Quality Documentation: Additional COC, EN10204 3.1/3.2 certificates on request. All test results digitally archived.

Conclusion & References

Utilizing aluminum casting die technology brings measurable advantages in cost, efficiency, quality, and sustainability for modern industrial applications. YDCASTINGS leverages leading alloys, CNC integration, and rigorous certification to ensure every structural parts link head meets or exceeds international standards. For detailed technical support, visit industry forums:

- Foundry-Planet.com (Industry news & case studies)

- Materials Journal (MDPI) (Peer-reviewed casting research)

- Journal of Materials Processing Technology

- ResearchGate: Modern Aluminum Die Casting